coil handling system makes efficient coil transportation for rolling mill

coil handling system makes efficient coil transportation for rolling mill

Coil Handling System

VERSATILE HANDLING SOLUTIONS

The finishing end of high-speed rod rolling mills and bar-in-coil mills plays a crucial role in the production of high-quality product. Upstream rolling and cooling components of the mill have worked in concert to make a high-quality product, with consistent size and coil shape. Now, the coil must be transported for further cooling, compacting and storage or shipment.

The rod coils need to be handledand compacted carefully to prevent damage, yet processed efficiently to keep up with production. Compacted coils must be tied or strapped firmly to withstand the rigors of shipment without scratching and deformation of the rod rings, avoiding risk of rejection by your customers.

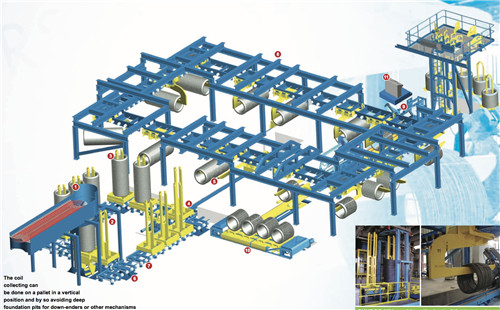

The SINOMTechnologies vertical stem pallet and horizontal hook carrier systems feature a modular design with standardized components for ease of maintenance. They can be custom configured to meet your specific needs for production and coil processing.

For compacting of coils, both horizontal and vertical compactor systems are available for seamless interfacing with the upstream

coil handling system and with the downstream unloaders to coil storage and shipment. Our compactors are versatile and can be offered with wire binding or strapping systems. The binding heads are designed to make a consistent, high-strength knot for safe transport through storage and shipping.

Our coil handling systems and compactors are supplied as complete mechatronic packages that combine mechanical and electrical components designed to be used together, with standard, proven modules that bring new value to any long rolling mill.

Contact informaiton:

Tel:

Mobile:

Web:

在线联系供应商

Other supplier products

| Used hot rebar Rolling Mill Equipment and Machine | Used hot rebar Rolling Mill Equipment and Machine Used Rolling Mill Equipment and Machine Used and reconditioned rolling mills, like flat wire rol... | |

| copper crusher for bullet testing,Crusher type pressure gauges | copper crusher for bullet testing,Crusher type pressure gauges Crusher type pressure gauges are used to determine the maximum pressure in the barre... | |

| hot narrow strip rolling mill production line | Steel-rolling Engineering Division is SINOM’s main technology engineering force. Steel-rolling Engineering Division has held good command of ... | |

| straighten and withdraw machine for equipment of CCM/straightener For con-casting | straighten and withdraw machine for equipment of CCM/straightener For con-casting withdrawal & straigthening machine /straightenerFor con-casti... | |

| oilless bearing/ sliding bearings/self-lubricating bearings/copper bushes/oil-less copper brushes supplier/manufacturer | oilless bearing/ sliding bearings/self-lubricating bearings/copper bushes/oil-less copper brushes supplier/manufacturer We are specializing in prod... |

Same products

| Uratech ER16 Collet Rack – CNC Collet Storage for ER, DR & RD 16 Series | 卖方: Uratech USA Inc | TheUratech ER16 collet rackis a premium storage solution designed for CNC shops, toolrooms, and m... | |

| Uratech Tool scoot cart for 50 taper tool holders | 卖方: Uratech USA Inc | Maximize efficiency in your machining operations with our50 taper CNC tool carts, the ultimate so... | |

| 3 in1 Decoiler Leveler Feeder | 卖方: Dongguan YouYi Precision Automation Equipment Co., Ltd. | 3 in1 Decoiler Leveler Feeder For Thin Plate(0.3-3.2mm) The 3-in-1 servo feederintegrates four f... | |

| NC Servo Feeder (0.1-3.0mm) | 卖方: Dongguan YouYi Precision Automation Equipment Co., Ltd. | NC Servo Feeder (0.1-3.0mm) Our standard servo feederis engineered for precision coil feeding of... | |

| Uratech 40 Taper CNC Tower – CAT 40 Tool Cart & CNC Tool Holder Storage | 卖方: Uratech USA Inc | TheUratech 40 Taper CNC Toweris the ultimate solution for organizing and protecting your CNC tool... |