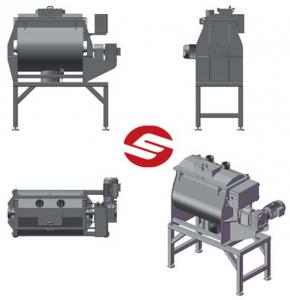

Single Shaft Paddle Mixer Machine

The structure of the single shaft paddle mixermachine is firm and stable. The mixing paddle and material contact is made of stainless steel. Single shaft paddle agitator mixerhas good corrosion resistance and keeps the quality and cleanness of the material without discoloration. The transmission mechanism adopts worm gear and worm to directly drive. It has no excessive noise when used, and has sufficient oil storage capacity to get good lubrication.

Instructions for Use And Precautions of Single Shaft Paddle Mixer Machine

Before use, perform a dry run test. Before the test, check the firmness of all the connecting parts of the machine, the amount of lubricating oil in the reducer and the integrity of the electrical equipment, then close the main switch and put on the power supply.

Empty running test. The empty running test shall be connected to the test according to the steps and functions of Article 15 of this manual.

If you need to scrape the groove wall material during operation, apply bamboo and wood tools, and do not use your hands to avoid accidents.

If the small plaster mixeris found to be abnormal in vibration or abnormal noise during use, stop it immediately.

the use of load should not be too large, generally measured by the load of the motor, with 380V motor in the heavy-duty current when mixing, no more than 6 amps is normal if the load should be reduced immediately to reduce the mixing capacity.

The shaft seals at both ends of the mixing paddle should be kept clean to avoid blackening and deterioration of the material.

Managers must be familiar with the technical performance, internal structure, and control structure of the machine. Do not leave the worksite during operation to prevent damage to the machine parts, so as to ensure safe production.

Structural Characteristics of Single Shaft Paddle Mixer Machine

(1) The single shaft paddle mixer machine is a batch mixer with excellent mixing uniformity.

(2) The gap between the rotor and the casing is small so that the materials can be fully mixed, and the bottom is full-length opening, material residue

small

(3) The two ends of the body are tightly sealed to prevent the leakage of the two shaft ends.

(4) The discharge door is pneumatically controlled, the action is more accurate and reliable, and the sealing performance is good.

(5) The machine is equipped with a liquid adding device, and the distribution is evenly dispersed.

(6) The overall structure is reasonable, the appearance is beautiful, and the operation and maintenance are convenient.

Application of Single Shaft Paddle Mixer Machine

Milk powder

Foodstuff

Medicinal

Chicken powder

Cosmetic Pigment

Other industries

Main Features of Single Shaft Paddle Mixer Machine

The paddles of different directions drive materials through different angles, mixing time approx. 3 to 5 minutes.

The rotating paddles will be filled with the chamber in a compact design, mixing evenness will be up to 99%.

There is only a 2-5mm gap between paddle and chamber, discharging outlet in open type.

Patent design can make sure the rotating shaft and discharging outlet has no leakage.

All with the polishing process in the chamber, there is no fastening pc such as nut, etc.

Full stainless steel 304 construct except hearing parts, very elegant and generous.

Technical Data of Single Shaft Paddle Mixer Machine

|

Technical Data |

|||||||

|

Model |

NDJ-200L |

NDJ-300L |

NDJ-500L |

NDJ-1000L |

NDJ-1500L |

NDJ-2000L |

NDJ-3000L |

|

Efficient volume |

200L |

300L |

500L |

1000L |

1500L |

2000L |

3000L |

|

Fully Volume |

280L |

400L |

680L |

1275L |

1820L |

2600L |

3900L |

|

Turning speed |

53RPM |

53RPM |

45RPM |

53RPM |

39RPM |

53RPM |

53RPM |

|

Total weight |

450KG |

650KG |

980KG |

1300KG |

1600KG |

2200KG |

2600KG |

|

Total power |

4KW |

11KW |

15KW |

22KW |

|||

|

Length(L) |

1800mm |

1900mm |

2050mm |

2500mm |

2950mm |

3330mm |

3350mm |

|

Wide(W) |

900mm |

1000mm |

1050mm |

1200mm |

1350mm |

1500mm |

1880mm |

|

Height(H) |

1110mm |

1200mm |

1250mm |

1350mm |

1400mm |

1650mm |

1950mm |

|

Power supply |

3 Phase AC208-415V 50/60HZ |

||||||

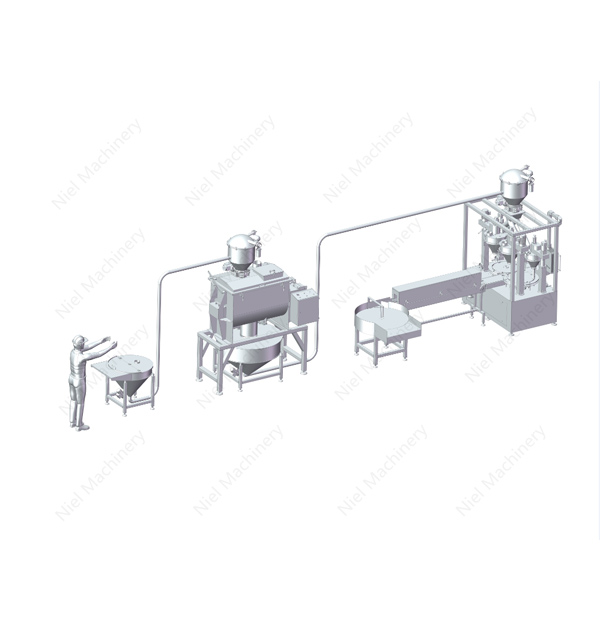

Shanghai Niel Machinery Manufacturing Co., Ltd. specializes in the design and production of bulk powder handling systems and ancillary equipment. NIEL MACHINERY always puts the interests of its customers first, and the company always adheres to the principle of good faith management. If you want to know more details or want a quotation, just feel free to contact us!

在线联系供应商

Other supplier products

| Bucket Elevator | The bucket elevator is suitable for lifting from a low place to a high place. After the material is supplied to the hopper through the vibrating ta... | |

| Conveying Equipment | The conveyor is a machine that frictionally drives the material in a continuous manner. It can be used to form a material conveying process on a ce... | |

| Cabinet Cyclone Dust Collector | Description of the powder dust collector The wind motor drives the machine to run. During the process of dust collecting, the dust will be adsorbed... | |

| Post Lifting Bin Mixer | The post lifting bin mixer can automatically complete the functions of lifting, mixing and lowering, and is ideal mixing equipment for the solid pr... | |

| Post Lifting Bin Mixer | The post lifting bin mixer can automatically complete the functions of lifting, mixing and lowering, and is ideal mixing equipment for the solid pr... |

Same products

| XD-MAX Winch for Drone | 卖方: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-MAX Winch for Drone The XD-MAX Winch for Droneis a high-performance aerial lifting solution d... | |

| XD-55 Winch for Drone | 卖方: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-55 Winch for Drone Introducing the XD-55 Winch for Drone—an advanced lifting system eng... | |

| XD-10 Winch for Drone | 卖方: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-10 Winch for Drone SAFE, EFFICIENT AND CONVENIENT.Your reliable and intelligent air transport... | |

| Uratech ER16 Collet Rack – CNC Collet Storage for ER, DR & RD 16 Series | 卖方: Uratech USA Inc | TheUratech ER16 collet rackis a premium storage solution designed for CNC shops, toolrooms, and m... | |

| Uratech Tool scoot cart for 50 taper tool holders | 卖方: Uratech USA Inc | Maximize efficiency in your machining operations with our50 taper CNC tool carts, the ultimate so... |