PU/PIR Continuous Sandwich Panel Production Line

Continuous pu sandwich panel machine chinaPIR Sandwich Panel Production Line, also called polyurethane sandwich panel manufacturing linemachine, is an automatic production line, which is consisting of decoiler, film coating, pre-cutting, cutting equipment, roll forming system, preheating, foaming, solidification, band saw cutting, cooling, stacking and packing. The whole PUpir sandwich panel machineintegrates technologies of mechanics, chemistry, electrical control, hydraulic pressure pneumatic and temperature control.

Jinggongis one of the leading sandwich board manufacturersin China who has been specialized in providing high-quality PIR/PU sandwich panel production line. The PU sandwich panel lines were exported to many countries, such as Poland, Brazil, Jordan, Kuwait, Saudi Arabia, Tunisia, and so on. The production line performance has got unanimous approval and favorable comment from domestic and international customers. Feel free to contact us for PIRPU sandwich panel production line price!

Zhejiang Jinggong Science & Technology Co., Ltd., which is located in Shaoxing, Zhejiang, developed the PU sandwich panel production line by themselves. This line has reached the world's advanced technology, stopped relying on import, and entered the time that there is no PU production line manufacturer in China. It means China localization age of PU production line is coming. The PU production line made by Jinggongconsists of decoiler, roll forming machine, preheating, high pressure foaming, double belt machine, bandsaw, stacking, packing and cooling, realizing an automatic production from uncoiling to packing. Max production speed is 12 meters per minute. Annual output is 1 million square meters.

Main Technical Parameters/Specifications of PU/PIR Continuous Sandwich Panel Production Line

|

Item |

Parameter |

|

|

Material |

Type |

Color steel sheet; galvanized sheet, Aluminum sheet |

|

Thickness |

||

|

Width |

≤1250(Max) |

|

|

Suitable size of panel |

Length |

2000-16000 |

|

Width |

600-1200 |

|

|

Thickness |

30-200 (Not including height of corrugation) |

|

|

Production speed |

3-8 (Adjustable) |

|

|

Valid length of double belt conveyor(mm) |

||

|

Work pressure on pouring foam |

150-200 |

|

|

Total power |

About 300 |

|

|

Total size(Length×Width×Height)(mm) |

130000×15000×6000 |

|

Features of PU/PIR Sandwich Production Line

Beautiful and applicable, multiple functions, such as thermal isolation, sound isolation and flame retardance.

Using heated air recycle oven, strictly control the temperature of PU foaming and solidification in suitable range.

Using high-pressure foaming system, precise measurement, high stability, little dust in the locale, protect the worker's health.

Using 141B or Pentane as foaming agent. Instead of carbon chloral-fluoride, make the PU foaming treatment become an environmental production craft.

Special double belt conveyor, flat surface of sandwich panel, even thickness, anti-pattern

Operation system controlled by PLC computer, personal design and simple operation.

在线联系供应商

Other supplier products

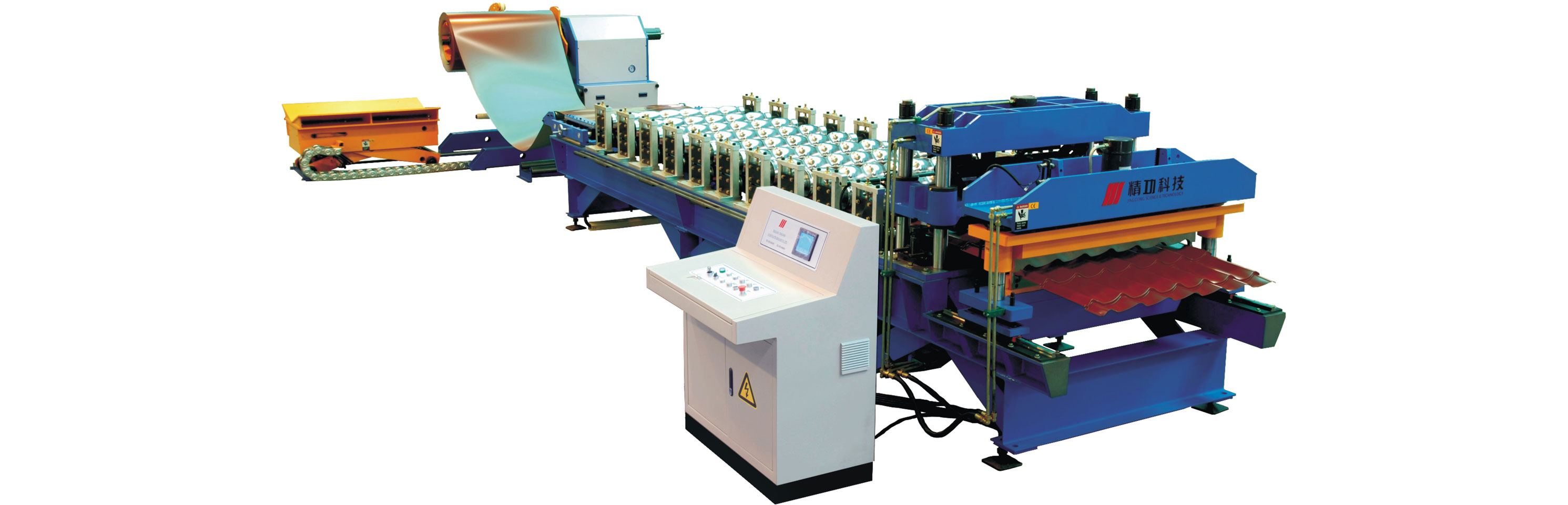

| High Speed Tile Forming Machine | This series of high-speed tile roll forming machineis a new-generational type roof tile roll forming machine with high speed and high-efficient, in... | |

| Rockwool Continuous Sandwich Panel Production Line | The rock wool sandwich panel lineis one continuous and automatic line that integrates mechanism, electrical controlling, hydraulic system and polyu... | |

| EPS Sandwich Panel Production Line | Main structure features ofEPS Sandwich Panel Machine 1) This EPS sandwich panel making machinehas the specification: nice appearance, low noise and... | |

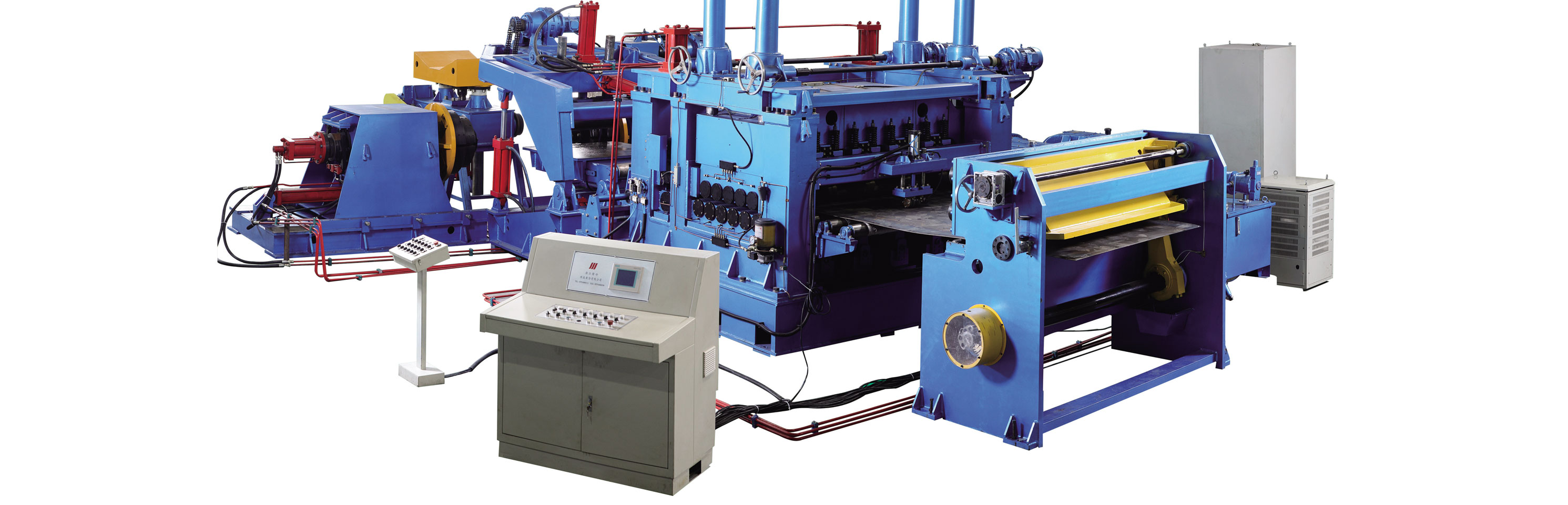

| Auxiliary Equipment | Here is the different types of auxiliary equipmentof our roll forming machine: curving punching forming machine, filming and cutting machine, slitt... | |

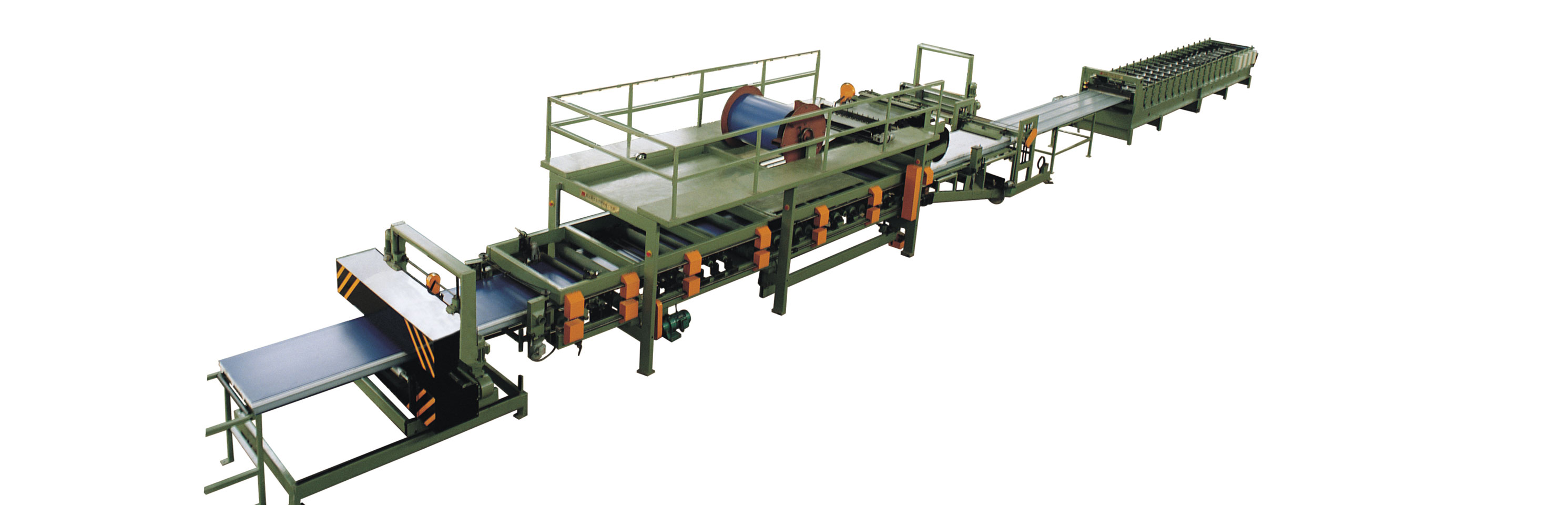

| Cut To Length Line | Thischina cut to length machineis special equipment for uncoiling, leveling, cutting and stacking the steel sheet according to the requirement of t... |

Same products

| Waste Aluminum Plastic Pyrolysis Plant | 卖方: Shangqiu Sihai Energy Technology Co.,Ltd | Waste Aluminum Plastic Pyrolysis Plant The refining of waste aluminum and plastic mainly uses a ... | |

| Continuous Tire/ Rubber Powder Pyrolysis Plant | 卖方: Shangqiu Sihai Energy Technology Co.,Ltd | Continuous Tire/ Rubber Powder Pyrolysis Plant Pyrolysis is the process of heating organic mater... | |

| Herbicide Supplier | 卖方: HEBEI LAIKE BIOTECH CO.LTD | Herbicide Supplier Wholesale Herbicide Suppliers - Laike Biotech is a professional supplier ... | |

| Press Fit Machine | 卖方: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Press Fit Machine Mainly used in the semiconductor packaging industry, it can be used for variou... | |

| Tri-Temperature Test Product | 卖方: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Tri-Temperature Test Product Mainly used in the semiconductor packaging industry, it can be used... |