Dixon Ring

Dixon Ring

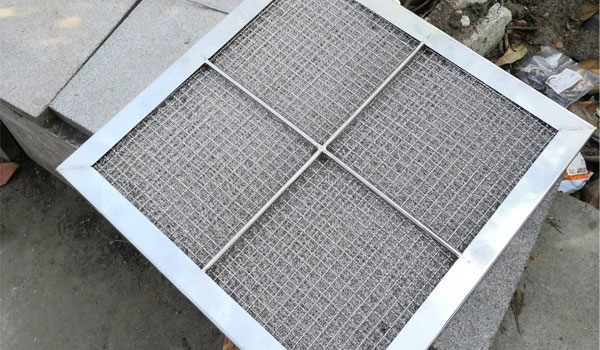

Dixon ringwas Originally designed by Dr George Olaf Dixon in 1946, it is a large development from Ceramic cross partition ring. Since it was born, Dixon ring was fine handmade, even after the automated process came up, the best quality Dixon ring is still fine handmade. The advantage of Dixon ring is high-efficiency mass transfer and extremely low-pressure drops.

Overview of Dixon Ring

Also known as Dixon packing, is a small particle of efficient packing, made of wire mesh or piercing-hole plate, the diameter and height of the packing is equal, mainly used in the laboratory and small batch packing, high purity product separation process.

The pressure drop of refillers is related to factors such as gas velocity, liquid spray amount, the weight of the material system, surface tension, viscosity, and properties of the fillers, as well as being related to preflooding treatment of the fillers. The conditions of the following data are operated under full reflux, and the operating pressure is normal pressure for reference.

Φ 1.5 x 1.5 Φ pressure drop in the 13 mm Φ tower is 70 ~ 400 mmh2o/m (cresyl ethane)

Φ 2.5 x 2.5 in the 50 mm Φ tower pressure drop is 55 ~ 250 mmh2o/m (cresyl ethane)

Φ 4 x 4 pressure drop in the 50 mm Φ tower is 30 ~ 200 mmh2o/m (water)

In addition, the hysteresis amount of reorganizing ring fillers is larger than that of solid fillers of the same kind, indicating that the surface wetting of reorganizing rings is more complete than that of general porcelain rings, leading to higher film formation rate and higher efficiency. As for fillers with smaller diameter, this is more obvious.

As the diameter of the tower increases, the number of theoretical plates decreases greatly(HETP = 0.8 ~ 1.2dr in Dr/d>10 but packing efficiency decreases significantly in Dr/d>70). The number of theoretical plates increases as gas velocity increases, but decreases as surface wetting rate decreases.15.

NAIKEproduces fillers for a single layer of silkscreen.

在线联系供应商

Other supplier products

| 4A MOLECULAR SIEVE | 4A Molecular Sieve NAIKEMolecular Sieve 4A is an alkali alumino silicate; it is the sodium form of the Type A crystal structure. 4A molecular si... | |

| MCM-41 Zeolite | MCM-41 show potential on catalytic cracking, residue hydrocracking, lube oil hydro finishing, alkylation, olefin polymerisation, separation of CO2 ... | |

| RASCHIG RING | Raschig ringsis also called cylindrical ring. It was invented by F. Rasching in 1914. As one of the earliest tower packing in the Chemical Industry... | |

| Ceramic Saddle Packing | Intalox saddles ceramicPacking is divided into two different types of products according to their properties, one is often used in the field of Che... | |

| Pad Demister With Frame/Mist Eliminator With Frame | NAIKEKnitted Wire Mesh is a kind of wire mesh knitted in particular type. It is used for wire mesh demister, oil-gas separator, dust remover, dedus... |

Same products

| Waste Aluminum Plastic Pyrolysis Plant | 卖方: Shangqiu Sihai Energy Technology Co.,Ltd | Waste Aluminum Plastic Pyrolysis Plant The refining of waste aluminum and plastic mainly uses a ... | |

| Continuous Tire/ Rubber Powder Pyrolysis Plant | 卖方: Shangqiu Sihai Energy Technology Co.,Ltd | Continuous Tire/ Rubber Powder Pyrolysis Plant Pyrolysis is the process of heating organic mater... | |

| Herbicide Supplier | 卖方: HEBEI LAIKE BIOTECH CO.LTD | Herbicide Supplier Wholesale Herbicide Suppliers - Laike Biotech is a professional supplier ... | |

| Press Fit Machine | 卖方: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Press Fit Machine Mainly used in the semiconductor packaging industry, it can be used for variou... | |

| Tri-Temperature Test Product | 卖方: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Tri-Temperature Test Product Mainly used in the semiconductor packaging industry, it can be used... |