Geothermal Well Drill Bits

Geothermal drilling characteristics of geothermal drilling the main oil and gas well drilling technology for reference, because the heat reservoir rock geological conditions, such as lithology, buried depth and output fluid property is different, compared with more demanding conditions of oil and gas drilling, geothermal drilling, but also for geothermal well characteristic of the high temperature and large diameter to new technology and new equipment improvement and development.

Characteristics of Geothermal Drilling

Compared with oil and gas drilling, geothermal drilling has the following characteristics:

- High temperature, great variation in buried depth.

- The rock is hard, abrasive and high in-situ stress heat storage rocks are mostly volcanic and metamorphic rocks. Compared with the deposition rock of oil and gas wells, the rock is hard, abrasive and high in-situ stress, and the stratum is broken and often unstable.

- The crack height is developed, and even centimeter-grade cracks exist.

Formation pressure is low and leakage is serious.

- The formation often contains corrosive fluid, which is corrosive to drilling string, casing, etc.

This requires the production of expensive titanium alloy bushing and the development of special cement.

- The geothermal well has a large diameter, many casing procedures and a large amount of cement.

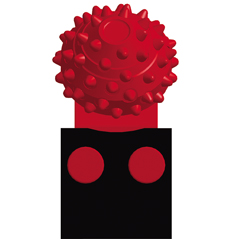

Recommended Geothermal Drilling Bits Types

Drilling a geothermal well is similar to drilling oil, gas and well. In order to overcome the special difficulties in drilling, drilling methods, flushing media, drilling tools, casing head structure, wellhead device and other appropriate technical measures should be adopted.

The drill pipe and drill collar with high-temperature resistance, corrosion resistance, low coefficient of thermal expansion and high strength should be used in the drill pipe and drill collar.

And we will recommend high-quality PDC bit and Tricone bit of GREAT.

Cangzhou Great Drill Bits Co.,Ltd.is a drill bit manufacturer, we have china rock drill toolsfor sale, rock drill bitand etc. For more information about drill bit types oil and gasand oil well drill bit types, please feel free to contact us!

在线联系供应商

Other supplier products

| PDC cutters used for PDC bit, PDC hole opener, PDC reamer | Overview of PDC Cutter PDC cuttersare made of diamond micro-powder and cemented carbide substrate sintered under ultra-high pressure and high te... | |

| The Cause of PDC Bit Balling | The Cause of PDC Bit Balling Ⅰ. The common phenomenon of PDC drill bit balling Ⅱ. Causes of PDC bit balling As one of ... | |

| Bi-center Bit | Overview ofbi center bit This type of bi center drill bitmainly used for medium to medium-hard compressive and abrasive formation, it has medium a... | |

| What Are the Advantages of an Oil Well Bit? | What Are the Advantages of an Oil Well Bit? The oil wellbitis one of the widely used drilling bits, which has the characteristics of adapting to a... | |

| How to Use Tricone Bit Appropriately? | How to Use Tricone Bit Appropriately? (1) According to the lithology of the drilled formation, the following principles should be followed when se... |

Same products

| Uratech ER16 Collet Rack – CNC Collet Storage for ER, DR & RD 16 Series | 卖方: Uratech USA Inc | TheUratech ER16 collet rackis a premium storage solution designed for CNC shops, toolrooms, and m... | |

| Uratech Tool scoot cart for 50 taper tool holders | 卖方: Uratech USA Inc | Maximize efficiency in your machining operations with our50 taper CNC tool carts, the ultimate so... | |

| 3 in1 Decoiler Leveler Feeder | 卖方: Dongguan YouYi Precision Automation Equipment Co., Ltd. | 3 in1 Decoiler Leveler Feeder For Thin Plate(0.3-3.2mm) The 3-in-1 servo feederintegrates four f... | |

| NC Servo Feeder (0.1-3.0mm) | 卖方: Dongguan YouYi Precision Automation Equipment Co., Ltd. | NC Servo Feeder (0.1-3.0mm) Our standard servo feederis engineered for precision coil feeding of... | |

| Uratech 40 Taper CNC Tower – CAT 40 Tool Cart & CNC Tool Holder Storage | 卖方: Uratech USA Inc | TheUratech 40 Taper CNC Toweris the ultimate solution for organizing and protecting your CNC tool... |