Plastic Toilet Seat Mold

Toilet seat mouldquality points: cover mold cycle, cover mold life, Parting line whether there are sharp edges? Is the cover wall thickness even? How to make covers are light and strong? How to design a good exhaust ? How to make your toilet cover polish durable? How to judge the molding cycle? how to set up the toilet temperature?

High-quality Plastic Toilet Seat MoldFor Sale

As the toilet cover need to be strong and durable, the surface need smooth and high polished, many defects may be in injection molding production, including rhymes, poor fusion, black spots, black lines, color difference, burning a so on, we choose PP for the part material,to ensure the toilet seat cover mouldquality and mold life, we need to choose steel with right hardness, we design the plastic toilet seat mold with reasonable/reliable construction and movements, the mold cycle is settled to meet the requirements of lowest cost, we add ribs to strong the covers, we make side core pulling bodies for demolding,we use hot runner to enhance the production quality and efficiency,and good cooling system is also very important.

Points of Making Toilet Seat Cover Mould

Choosing the right material for the cover, PP could make the parts with good strength, good rigidity, good dimensional stability, and good coloring performance.

Designing the proper injecting system to ensure the plastic material could be heating melt well and venting.

Choosing the good mold material and inserts to ensure the high quality of the toilet seat casting mold.

Using the hot runner for cost-saving and enhancing the quality of the parts.

Using robots to pick up the parts during production can also enhance production efficiency.

Following our construction to install and use the toilet seat cover mould, to make sure there's no any damage for the mold and less repair.

Green Vitality Industry is a professional plastic injection manufacturerin various industries since 1993. We provide custom plastic injection mold, toilet seat cover mold, mould on toilet seat, mold on toilet seat, injection molds for saleand etc. Want to know more, contact us.

在线联系供应商

Other supplier products

| LCD TV Mould | LCD TV Mould TV screen frame mold is used to produce TV screen frames, it should be strong and assembly well with the screen. It has an undercut... | |

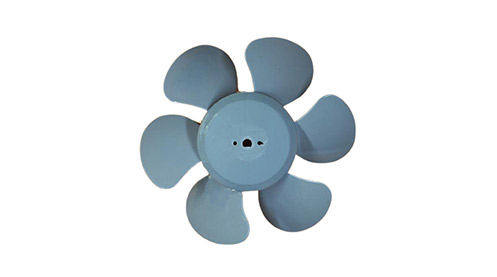

| Fan Mold | If the weight of each fan blade is not balanced, large vibration, high noise, and large wear of the rotating shaft will occur during high-speed rot... | |

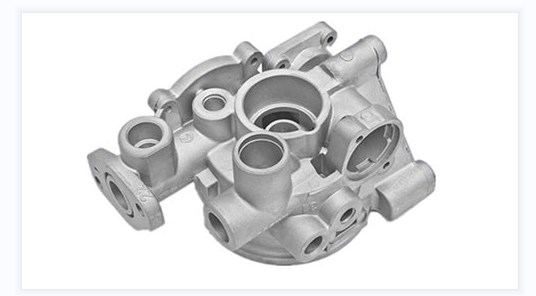

| Aluminum Die Casting Mold | Aluminum High Pressure Die Casting Mold When working at high or low temperatures, they also maintain good mechanical properties and have good co... | |

| Plastic Gear Mold | Injection molded plastic gearsis one of the most widely used transmission mechanisms in the field of instruments & meters, timers, reducers, ca... | |

| Plastic Enclosure Mold For Electronic Device | In a Lego game, you will hold the laser, sit on the device, and shoot various targets. Since this game is mainly to meet the gaming experience of L... |

Same products

| Uratech ER16 Collet Rack – CNC Collet Storage for ER, DR & RD 16 Series | 卖方: Uratech USA Inc | TheUratech ER16 collet rackis a premium storage solution designed for CNC shops, toolrooms, and m... | |

| Uratech Tool scoot cart for 50 taper tool holders | 卖方: Uratech USA Inc | Maximize efficiency in your machining operations with our50 taper CNC tool carts, the ultimate so... | |

| 3 in1 Decoiler Leveler Feeder | 卖方: Dongguan YouYi Precision Automation Equipment Co., Ltd. | 3 in1 Decoiler Leveler Feeder For Thin Plate(0.3-3.2mm) The 3-in-1 servo feederintegrates four f... | |

| NC Servo Feeder (0.1-3.0mm) | 卖方: Dongguan YouYi Precision Automation Equipment Co., Ltd. | NC Servo Feeder (0.1-3.0mm) Our standard servo feederis engineered for precision coil feeding of... | |

| Uratech 40 Taper CNC Tower – CAT 40 Tool Cart & CNC Tool Holder Storage | 卖方: Uratech USA Inc | TheUratech 40 Taper CNC Toweris the ultimate solution for organizing and protecting your CNC tool... |