Plastic Gear Mold

Injection molded plastic gearsis one of the most widely used transmission mechanisms in the field of instruments & meters, timers, reducers, cameras, copiers, fax machines, shredders, printers, vacuum cleaners, automatic coffee machines DVD moving support, automotive rearview mirrors, headlight regulators, toy movement, medical devices.

Precision gears have very high requirements in terms of dimension and performance, minor deformation will affect the performance of the gear system, it might cause unstable moving, vibration, shaking, or noise. Therefore, it is very important to prevent deformation in the process of injection molding.

High-quality Injection Mold For Precision Gear

Precision is the most essential factor when our team designed gear mold. We adopted steel material S316 with stable properties which are suitable for precise injection molding. The gears produced by this mold are operating reliably and transmit stably.

Basic Information for Plastic Gear Mold

Plastic Gear MoldingSpecification

Features of Plastic Injection Molding Double Spur Gear

The Small Plastic Double Spur Gear is made of POM.

POM product has high rigidity and sound abrasion resistance, the size of the gear is precise for perfect assembly. It is of good self-lubricating property on the surface for smooth transmission.

How to Choose A Good Quality Precision Plastic Gear Mold

There are straight spur gear, helical gear, internal gear. herringbone gear, straight bevel gear, spiral bevel gear, zero bevel gear, worm gear, screw gear, concave worm gear, hypoid gear, face gear, and more, choose the suitable gear system for the internal driver of your devices.

ISO, AGMA, DIN, JIS are the Precision Standard of Gears.

When you check the quality of gears, please pay attention to the precision of gear motion, gear working stability, and tooth contact accuracy

The good quality gear system is suitable for high-speed movement and has a long working life.

Green Vitality Industry is a professional plastic moulding companyin various industries since 1993. We provide injection molding dies for sale, auto lamp mould, plastic mouldand etc. Want to know more, contact us.

在线联系供应商

Other supplier products

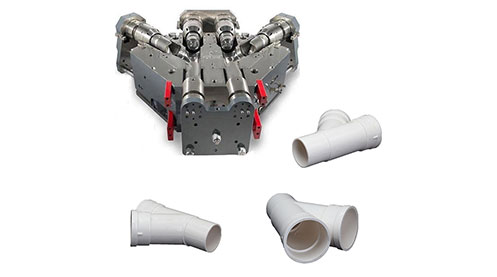

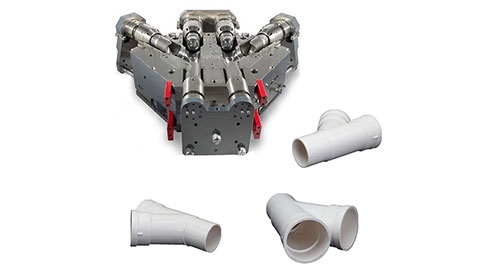

| PVC Pipe Fitting Mould | PVC fitting mould is playing an important role in the pipeline systems, they are used for connection, control, direction change, diversion, sealing... | |

| PVC Pipe Fitting Mould | PVC Pipe Fitting is playing an important role in the pipeline systems, they are used for connection, control, direction change, diversion, sealing,... | |

| Mouse Mold | One computer mouse usually includes these plastic parts: a bottom shell, an upper cover, a middle cover, a wheel, a base of wheel, a frame which co... | |

| Car Light Mould | The car light mould plays a vital role in illuminating vehicles, serving as the eyes of cars. It encompasses all the lighting systems employed in a... | |

| Keyboard Mould | Mainly electronic molds we make are electronic housing mold, electronic components mold, electronic dashboard cover mold, computer keyboard mold, c... |

Same products

| XD-MAX Winch for Drone | 卖方: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-MAX Winch for Drone The XD-MAX Winch for Droneis a high-performance aerial lifting solution d... | |

| XD-55 Winch for Drone | 卖方: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-55 Winch for Drone Introducing the XD-55 Winch for Drone—an advanced lifting system eng... | |

| XD-10 Winch for Drone | 卖方: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-10 Winch for Drone SAFE, EFFICIENT AND CONVENIENT.Your reliable and intelligent air transport... | |

| Uratech ER16 Collet Rack – CNC Collet Storage for ER, DR & RD 16 Series | 卖方: Uratech USA Inc | TheUratech ER16 collet rackis a premium storage solution designed for CNC shops, toolrooms, and m... | |

| Uratech Tool scoot cart for 50 taper tool holders | 卖方: Uratech USA Inc | Maximize efficiency in your machining operations with our50 taper CNC tool carts, the ultimate so... |