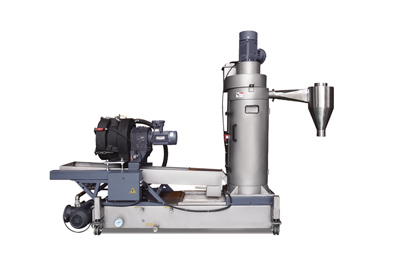

KEYA Twin Screw Extruder

With more than 20 years of industry experience and installation practice of more than 8000 production lines, Nanjing KY Chemical Machinery Co., Ltd. provides global customers with optimal cost performance and reliable compouding extrusion systems. Our twin screw extrusion machine models range from laboratory test samples by using lab scale twin screw extruder to polyolefin granulation engineering for petrochemical enterprises to meet the latest needs of various related industries.

The compounding system covers various process steps from material handling, metering feeding, step-by-step feeding, compounding extrusion, melt filtration or pressurization, pelletizing, conveying and cooling, drying, storage homogenization to packaging. With years of technological experience and strong strength, Nanjing KY Chemical Machinery Co., Ltd., as a professional extruder machine manufacturer, has selected and trained many powerful suppliers to provide customers with a complete set of small twin screw extruders. The compounding system of our plastic extrusion equipment for salecan effectively eliminate the repetitive work of communication between customers and dozens of suppliers, greatly saving the twin screw extruder cost and the time limit of buying twin screw extruder for customers, and finally obtain the best return on investment. If you want to buy twin screw extruder, you can check our different types of twin screw extruder for sale below. Or you can contact us directly and consult for more information about plastic extrusion equipment for sale and twin screw extruder machine price.

The Features of the Twin Screw Extruder

The industrial ethernet control system, using internal communication technology. Allow the operation in the field, control room, and remote.

The modular system. The system of our twin-screw extruders can be expanded or reformed according to the actual demands.

The combination of imported technology and independent research and development technology.

Specially adapted upstream equipment for feeding.

Easy to maintain and clean.

Come and buy twin screw extruder. / Come and get twin screw extruder cost. / Come and get double screw extruder price.

How Does Reliable and Easy-to-use Control System of Twin Screw Machine Work?

How many devices need how many control units? How do different control units work together? KY's work is to provide a comprehensive, reliable, and easy-to-use control system for the whole compounding system. This is an integrated control system based on industrial ethernet, which provides a new control standard for customers. The control of each extruder pelletizer can be connected to ethernet, using internal communication technology, and can be operated in the field, control room, or remote. At the same time, the system has flexibility and diversity, tailor-made for customer projects.

Aiming at the different production scale and different material production process, the plastic extrusion equipment for sale of our compounding system vary greatly. To satisfy different customers and different standard control systems, KY provides reliable and easy-to-use solutions for customers. By adopting the modular system, the system of our twin-screw extruders can be expanded or reformed with the expansion of production scale or the renewal of process, and seamlessly integrated with the existing general operating system. Our twin-screw extruder can significantly reduce user costs and saves learning time, so as to meet customers' requirements for continuous improvement of product quality and cost control.

What is the Difference Between Single Screw and Twin Screw Extruder?

Price: While the single screw extruder has a simple structure and low price, the twin-screw extruder holds a more complicated structure and therefore, higher prices.

Plasticizing Ability: Single screw machine is suitable for plasticizing extrusion of polymer and for extrusion processing of granular material. As for the single screw machine, the shear degradation of polymer is small, but the residence time of the material in the extruder is relatively long. In contrast, the twin-screw extruder pelletizer has good mixing and plasticizing ability, and the material normally stays in the extruder pelletizer for a short time, which is suitable for powder processing.

Processing Capacity and Energy Consumption: Unlike a single-screw machine, the twin extrusion screw for sale has a large output, fast extrusion speed, and low energy consumption per unit output.

Operation: The operation for the single screw extruder is easy and the process control is simple; whereas, the operation of the twin-screw extruder is relatively complicated and the process control requirements are high.

Buy from extrusion machine manufacturers.

在线联系供应商

Other supplier products

| SK53 Twin Screw Extruder | Overview of SK53 Twin Screw Extruder SK53 mini twin screw extrudercan be used in engineering plastics, color masterbatch, functional masterbatch, ... | |

| AKW Series Water Ring Pelletizer | For some materials such as elastomers with low hardness or easy adhesion, it is recommended to use a water ring pelletizer for granulation. After e... | |

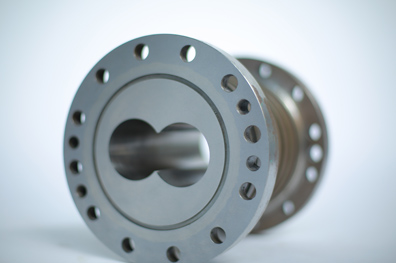

| Barrels | The body of the basic grade barrel is made of 45 # steel. The liner of the barrel is made of basic alpha-101 bimetallic material. The high-grade... | |

| KEYA Twin Screw Extruder | With more than 20 years of industry experience and installation practice of more than 8000 production lines, Nanjing KY Chemical Machinery Co., Ltd... | |

| HK Large Extruder Production System | Founded in 1993, Nanjing KY Chemical Machinery Co., Ltd. is currently one of the largest parallel co-rotating twin screw extrusion machinesuppliers... |

Same products

| Inclined Belt Planetary Vertical Shaft Concrete Mixing Plant | 卖方: Yousheng Machinery Equipment Co.,Ltd | Inclined Belt Planetary Vertical Shaft Concrete Mixing Plant Why Choose anInclined Belt Planetar... | |

| Improved Vertical Shaft Planetary Concrete Mixing Plant With Hopper Lift | 卖方: Yousheng Machinery Equipment Co.,Ltd | Improved Vertical Shaft Planetary Concrete Mixing Plant With Hopper Lift Vertical Shaft Planetar... | |

| High-Discharge Mobile Concrete Batching Plant | 卖方: Yousheng Machinery Equipment Co.,Ltd | High-Discharge Mobile Concrete Batching Plant High-Discharge Mobile Concrete Batching Plantinteg... | |

| Forced Mobile Concrete Plant | 卖方: Yousheng Machinery Equipment Co.,Ltd | Forced Mobile Concrete Plant Introducing our versatile forced concrete mixer: compact for tight ... | |

| Waste Aluminum Plastic Pyrolysis Plant | 卖方: Shangqiu Sihai Energy Technology Co.,Ltd | Waste Aluminum Plastic Pyrolysis Plant The refining of waste aluminum and plastic mainly uses a ... |