PP Meltblown Non-woven Fabric Production Line

During the outbreak of COVID-19 in 2019, our company JWELL took the lead in developing a complete production line capable of successfully producing high-quality PP meltblown fabrics with many years of experience in textile and weaving equipment. The whole company worked hard and delivered tens of thousands of production lines, making great contributions to alleviating the epidemic at that time, also exporting many high quality pp non woven fabric making machineto many countries.

Advantages of PP Meltblown Non-woven Fabric Production Line

We provide complete project solution for you from raw material to plant planning, which means that even you have no experience of this product, we will support you.

The melt blown mold adopts the latest runner design to ensure the uniformity and high accuracy of the melt blown cloth, and the manufacturing cost is expensive.

High-accuracy vacuum and temperature control system.

Equipped with double-station screen changer.

Intelligent control system helps you know details data of each part of this machine line in real time. Easy operation and energy saving.

Introduction of PP Meltblown Non-woven Fabric Production Line

PP meltblown non-woven fabric is mainly made of polypropylene, and the fiber diameter can reach 1-5 microns. There are many voids, fluffy structure, and good anti-wrinkle ability. These ultrafine fibers with unique capillary structure increase the number and surface area of fibers per unit area, so that the meltblown cloth has good filterability, shielding, heat insulation and oil absorption.

The complete production process of PP melt blown cloth making machineincludes raw material mixing, dryer, extrusion, screen changer, metering pump, mold, distribution plate, spinneret, netting and ending winding device. The production of melt-blown cloth is relatively complicated and has high requirement for equipment manufacturing, as well as, reliable service during the whole production process is also indispensable.

Introduction of Spunbond Nonwoven Fabric Production Line

Spunbonded non-woven fabric is used for clothing, medical and sanitary materials.

Our spunbonded non-woven fabric production line is mainly used to produce PP spinning and hot rolling reinforced non-woven fabrics. PP Spunbond hot-rolled non-woven fabrics with different colors, properties and applications are produced with PP as the main raw material, added into color masterbatch and additives such as antioxidant, anti pilling and flame retardant. Our spunbonded non-woven fabric production line can produce S, SS, SSS and other series products by changing different technical configurations to meet the market demand of PP Spunbond Nonwoven Fabrics for different purposes.

Introduction of SMS Spinning Melt Composite Nonwoven Fabric Production Line

This production line is used to produce nonwoven fabrics for medical isolation clothing, surgical clothing, sheets curtain, sanitary napkins, baby diapers, adult incontinence pad and other disposable medical protection and personal health care industry, etc.

SMS spinning melt composite non-woven non-woven fabric is made of spunbond non-woven fabric + melt blown non-woven fabric + spunbond non-woven fabric through three-layer web hot rolling composite. Our company has mastered a full set of one-step SMS spinning melt composite nonwoven production process and technology. The production line adopts high-precision die spinneret, and the products are finer and more uniform, and the fabric texture is more soft, which can greatly meet the needs of different customers

The Application of PP Meltblown Non-woven Fabric Production Line

PP meltblown non-woven fabric can be used in the fields of air, liquid filter materials, face mask materials, thermal insulation materials, oil-absorbing materials etc. With our constant attention to public health, meltblown products become indispensable.

As a plastic extruder machine factory, we can offer high quality hdpe pipe extruder machinefor sale, if you are interested, please contact us.

在线联系供应商

Other supplier products

| PVC Window Profile Extrusion Line | Our high quality PVC window profile extrusion line equipped with special conical twin screw extruder or parallel screw extruder which is more suita... | |

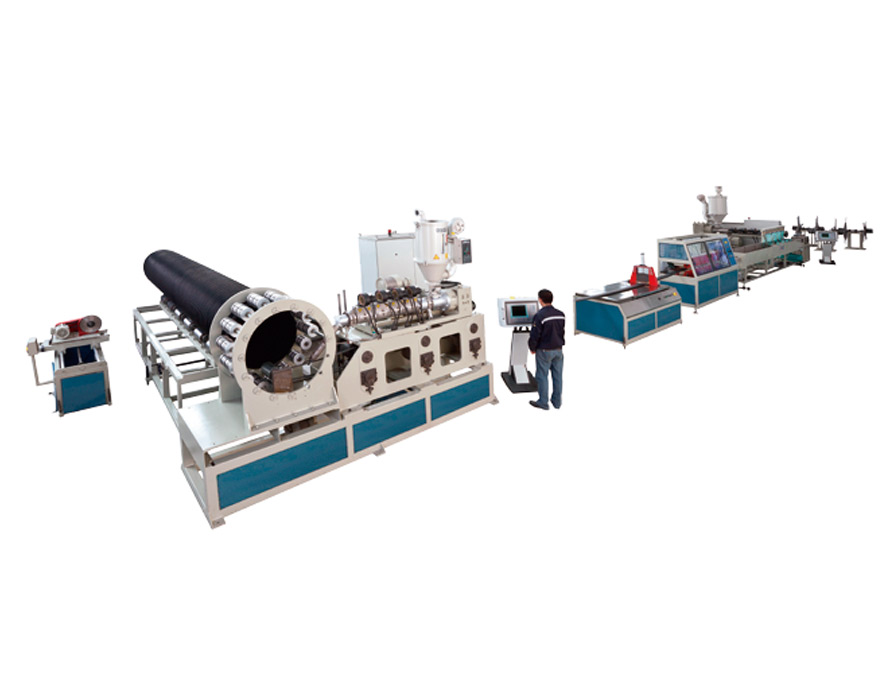

| High Pressure RTP Twisted Composite Pipe Extrusion Line | As a leading pipe extrusion machine line supplier, Jwell provides quality composite pipe extrusion production lines for RTP. RTP (Reinforced Thermo... | |

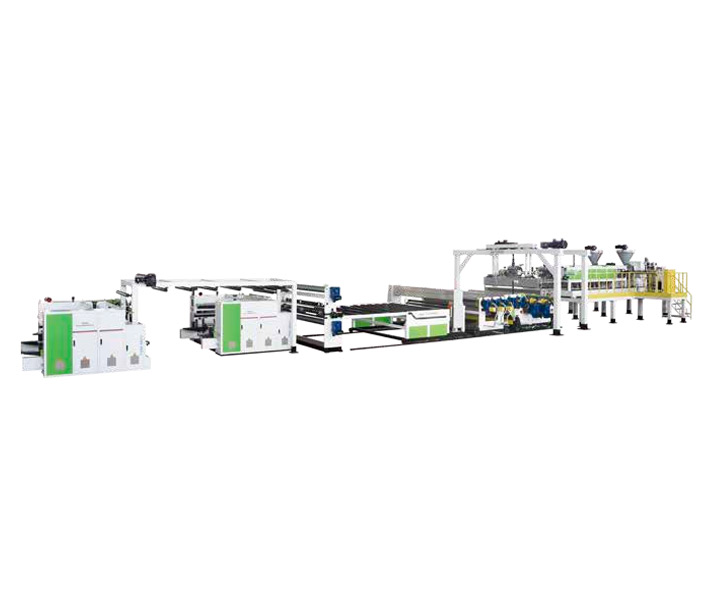

| Film Extrusion Line | We have own experimental institution and professional company to research and develop high-performance plastic film extrusion machines. The main fi... | |

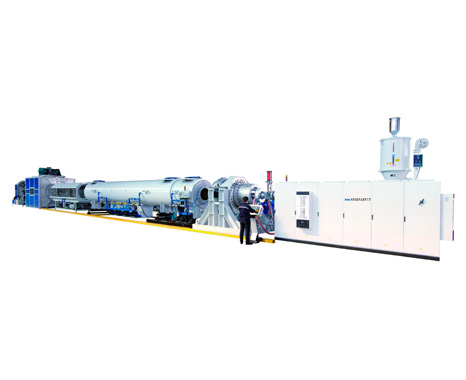

| HDPE Pipe Extrusion Line | Our single screw extruder series offers high performance in terms of HDPE pipe production and melt homogeneity. The full HDPE extrusion lineadopts ... | |

| PVC Foam Board Extrusion Line | We have researched and developed on PVC skinning foam board extrusion machine for over 25 years, and have exported thousands of full PVC foam board... |

Same products

| Waste Aluminum Plastic Pyrolysis Plant | 卖方: Shangqiu Sihai Energy Technology Co.,Ltd | Waste Aluminum Plastic Pyrolysis Plant The refining of waste aluminum and plastic mainly uses a ... | |

| Continuous Tire/ Rubber Powder Pyrolysis Plant | 卖方: Shangqiu Sihai Energy Technology Co.,Ltd | Continuous Tire/ Rubber Powder Pyrolysis Plant Pyrolysis is the process of heating organic mater... | |

| Herbicide Supplier | 卖方: HEBEI LAIKE BIOTECH CO.LTD | Herbicide Supplier Wholesale Herbicide Suppliers - Laike Biotech is a professional supplier ... | |

| Press Fit Machine | 卖方: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Press Fit Machine Mainly used in the semiconductor packaging industry, it can be used for variou... | |

| Tri-Temperature Test Product | 卖方: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Tri-Temperature Test Product Mainly used in the semiconductor packaging industry, it can be used... |