AEROSPACE CNC MACHINING

DEED Precision uses advanced technology and the best engineering solutions to provide the most accurate parts for aerospace-with fewer changes and the lowest possible cost.

Focusing on the market, it covers aerospace and its components, including aircraft structural components, turbomachinery components and related (by process and/or material) products.

CNC machining aerospace parts manufacturing

DEED Precision's machines have a wide range of sizes, flexibility and adaptability, which are very suitable for the manufacture of aircraft structural components. Available machine platforms can contain three, four, five axes, with a working area and stroke of up to 20 meters-which can accommodate the largest structural components.

--The spindle speed and torque can be customized for processing specific materials

--Provide industry-leading performance for processing aircraft structural components.

--Almost all machines can be integrated into the automation system.

Aircraft engine manufacturing

With numerous grinder, EDM and milling machine options, DEED machines are ideal for the manufacture of aircraft engines and other turbomachinery parts.

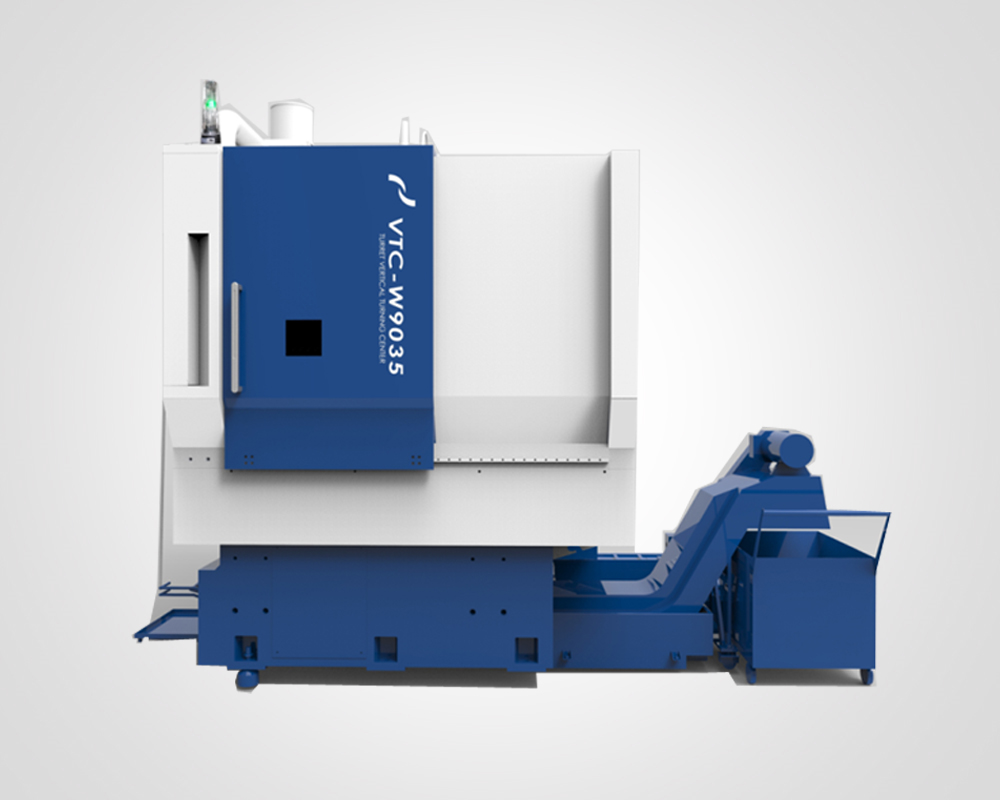

Grinding Machines for aerospace cnc machining

In addition to traditional milling machines, DEED also offers flexible grinding centers that can provide grinding capabilities on a multi-axis machining center platform. This allows traditional milling and drilling to be performed on the same machine. It also enables cnc machining aerospace parts to be machined with the fewest set-ups, resulting in the smallest tolerance stack-up and the greatest accuracy.

Milling Machine for aerospace cnc machining

Various sizes and spindle characteristics can be customized. Three-axis, four-axis, and five-axis working areas and strokes can handle most engine parts, and can match the platform with the cnc machining aerospace parts being processed according to size, feature geometry and material. The combination of high-performance motion control and high-performance axis features can create very precise multi-axis motions, while contouring, moving features to features, or at the same time. This ability is particularly beneficial in shaping the contour of the surface of the cnc machining aerospace parts. The spindle speed and torque can be selected and optimized for the specific materials involved.

在线联系供应商

Other supplier products

| HBC SERIES CNC HORIZONTAL BORING AND MILLING CENTER FOR SALE | HBC Series is our CNC horizontal boring machine. According to the different sizes, we have HBC1116 CNC horizontal boring machine and HBC1316 CNC ho... | |

| HORIZONTAL TURNING CENTER SPECIAL FOR WHEEL HUB | The machine tool bed adopts "mineral casting" material and technology of Germany, which guarantees DEED CNC machine tool with better performance on... | |

| HBC SERIES CNC HORIZONTAL BORING MILL FOR SALE | HBC SERIES CNC HORIZONTAL BORING MILLFOR SALE HBC Series is our CNC horizontal boring machine. According to the different sizes, we have HBC1116... | |

| UNIVERSAL HORIZONTAL LATHE | The machine tool adopts the mainstream oblique bed structure of Europe, America, and Japan, with integrated electromechanical, hydraulic, and gas d... | |

| CNC LATHE | CNC LATHE ADVANTAGES Imported spindle unit specially ordered according to industry needs. V-ribbed belt transmission, more stable. Multiple seali... |

Same products

| Inclined Belt Planetary Vertical Shaft Concrete Mixing Plant | 卖方: Yousheng Machinery Equipment Co.,Ltd | Inclined Belt Planetary Vertical Shaft Concrete Mixing Plant Why Choose anInclined Belt Planetar... | |

| Improved Vertical Shaft Planetary Concrete Mixing Plant With Hopper Lift | 卖方: Yousheng Machinery Equipment Co.,Ltd | Improved Vertical Shaft Planetary Concrete Mixing Plant With Hopper Lift Vertical Shaft Planetar... | |

| High-Discharge Mobile Concrete Batching Plant | 卖方: Yousheng Machinery Equipment Co.,Ltd | High-Discharge Mobile Concrete Batching Plant High-Discharge Mobile Concrete Batching Plantinteg... | |

| Forced Mobile Concrete Plant | 卖方: Yousheng Machinery Equipment Co.,Ltd | Forced Mobile Concrete Plant Introducing our versatile forced concrete mixer: compact for tight ... | |

| Waste Aluminum Plastic Pyrolysis Plant | 卖方: Shangqiu Sihai Energy Technology Co.,Ltd | Waste Aluminum Plastic Pyrolysis Plant The refining of waste aluminum and plastic mainly uses a ... |