Induction Hardening

The induction hardening process is a very important way in the manufacturing process of heat treatment of mechanical parts. In order to improve the hardness of metal's surface, not only should the surface layer depth of the workpiece reach the industrial design standard, but the heat treatment production plants are also needed to introduce the hardening process in the production. Functioning as an effective tool to implement the induction hardening process of steel, the induction hardening machine occupies an irreplaceable position in many heating methods, especially in the control of layer depth and temperature control. As a mature induction hardening machine manufacturers, JKZ sells 1-10KHZ medium frequency induction furnaces, 15-30KHZ ultrasonic frequency induction heaters, 30-60KHZ high-frequency induction heating machines, and 50-120KHZ super high-frequency small induction heating machines of high quality. These induction hardening machines hold the power range from 7.5KW to 600KW, which can process workpieces with a diameter up to 2000mm and hardening depth from 1 to 20mm. Moreover, capable of working together with CNC/PLC hardening machine scanner system, JKZ's Induction heating equipment can also accurately control the induction heating coil moving speed, workpiece rotation speed, power output percentage, layer depth, and quenching liquid spray time. Thus, if you are still looking for a tool to conduct effective application of induction surface hardening, our industrial heating unit can then perfectly meet all your needs for the hardening and heating processes.

Induction Hardening VS Case Hardening

Comparing the two methods of quenching steel workpieces, the first significant difference is part handling. Surface hardening can process a large number of workpieces at the same time, while induction hardening focuses on a single workpiece. Through induction hardening, the parts are quenched one by one.

Case hardening relies on parts logistics to transport parts between the production line and hardening. Induction hardening can be directly integrated into the production line as part of the cycle with a suitable hardening machine.

Case hardening in detail

As mentioned above, surface hardening is carried out in batches. As with induction hardening, the goal is to harden the outer layer of the workpiece.

In the case of quenching, the workpiece is hardened by carburizing. The steel is heated above 880°C to become austenite. The coal is then transferred from the CO emission medium to the part through the surface of the part. Diffusion causes the edges of the workpiece to receive more carbon, while the carbon density in the center remains the same.

There are two ways to influence the depth of hardening in surface hardening: one is to manipulate the heating of the workpiece, for example, by using a special paste to prevent certain places from being heated. The other is by influencing the quenching process, for example by immersing only certain parts of the workpiece.

Using these two methods, the results are not particularly accurate, and can only be reproduced within a relatively wide tolerance range. This is very different from induction hardening.

Induction hardening in detail

As mentioned above, each part is individually quenched using induction hardening technology. Each part is heat treated, quenched and annealed separately. In addition to being integrated into the production line, the great advantage of induction hardening is the precise control and reproducibility of the quenching results. In order to achieve this, the entire hardening process from the inductor and the applied energy and frequency to quenching and annealing has been specifically adjusted for the relevant workpiece. Even for workpieces with complex geometries, this can produce excellent quenching results.

Which Hardening Method is Better?

Which hardening process is suitable for the application depends on many factors. Both case hardening and induction hardening methods have their own advantages and disadvantages. However, for the mass production of medium or high-volume parts, induction hardening provides a series of benefits:

Using a suitable induction hardening machine, induction hardening can be fully integrated into the cycle of the production line and automated.

Especially induction hardening, the result is repeatable, which helps to maintain high quality in production. This greatly reduces the unit cost

As a professional induction heater factory, JKZ has high-quality induction heating inverterfor sale. Welcome to contact us if needed.

在线联系供应商

Other supplier products

| Induction Heating Machines | JKZ Electronic has been engaged in the manufacturing of induction heating equipment for nearly 30 years. At present, there are currently more than ... | |

| Induction Heating Machines In Carbide Production | Hard alloy carbide is an important raw material for cutter heads. At present, most of the manufacture of cemented carbide cutting tools uses high-f... | |

| SWP-MT 15KHz-30KHz Medium Frequency Induction Heating Machine | SWP 300series are JKZ's newly designed and manufactured induction heating power supply. The MT version of SWP series equipment uses IGBT as the ... | |

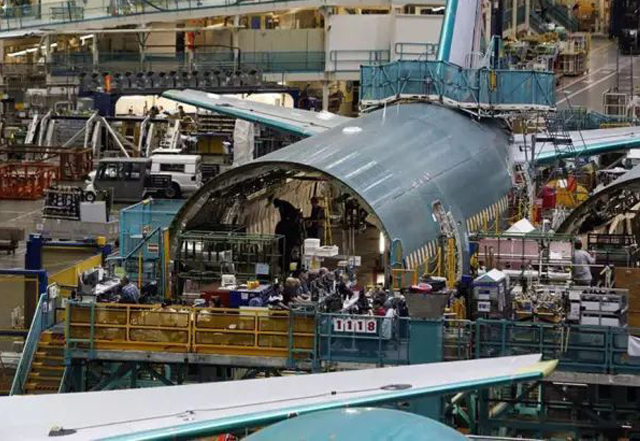

| Induction Heating Machines In Aviation And Aerospace | Aviation and aerospace are manifestations of high standard industrial capabilities. Induction heating is widely used in the aerospace industry, and... | |

| CX2030C 50-120KHZ 30KVA 23A High Frequency Induction Heating Machine | CX2030C 50-120KHZ high-frequency MOSFET type induction heating equipmentholds the output power of 15KW/30KVA. It is suitable for soldering, welding... |

Same products

| XD-MAX Winch for Drone | 卖方: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-MAX Winch for Drone The XD-MAX Winch for Droneis a high-performance aerial lifting solution d... | |

| XD-55 Winch for Drone | 卖方: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-55 Winch for Drone Introducing the XD-55 Winch for Drone—an advanced lifting system eng... | |

| XD-10 Winch for Drone | 卖方: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-10 Winch for Drone SAFE, EFFICIENT AND CONVENIENT.Your reliable and intelligent air transport... | |

| Uratech ER16 Collet Rack – CNC Collet Storage for ER, DR & RD 16 Series | 卖方: Uratech USA Inc | TheUratech ER16 collet rackis a premium storage solution designed for CNC shops, toolrooms, and m... | |

| Uratech Tool scoot cart for 50 taper tool holders | 卖方: Uratech USA Inc | Maximize efficiency in your machining operations with our50 taper CNC tool carts, the ultimate so... |