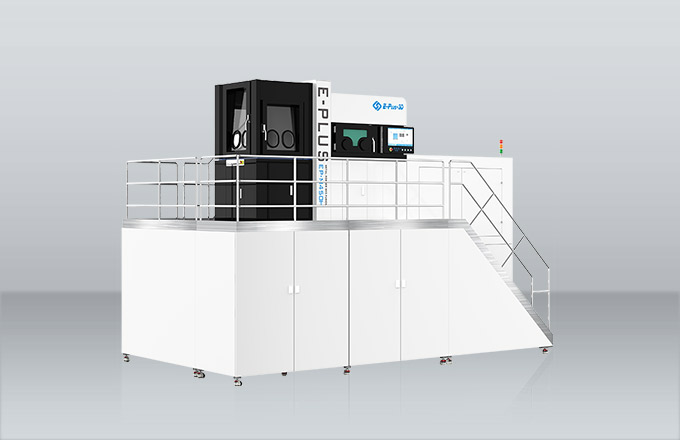

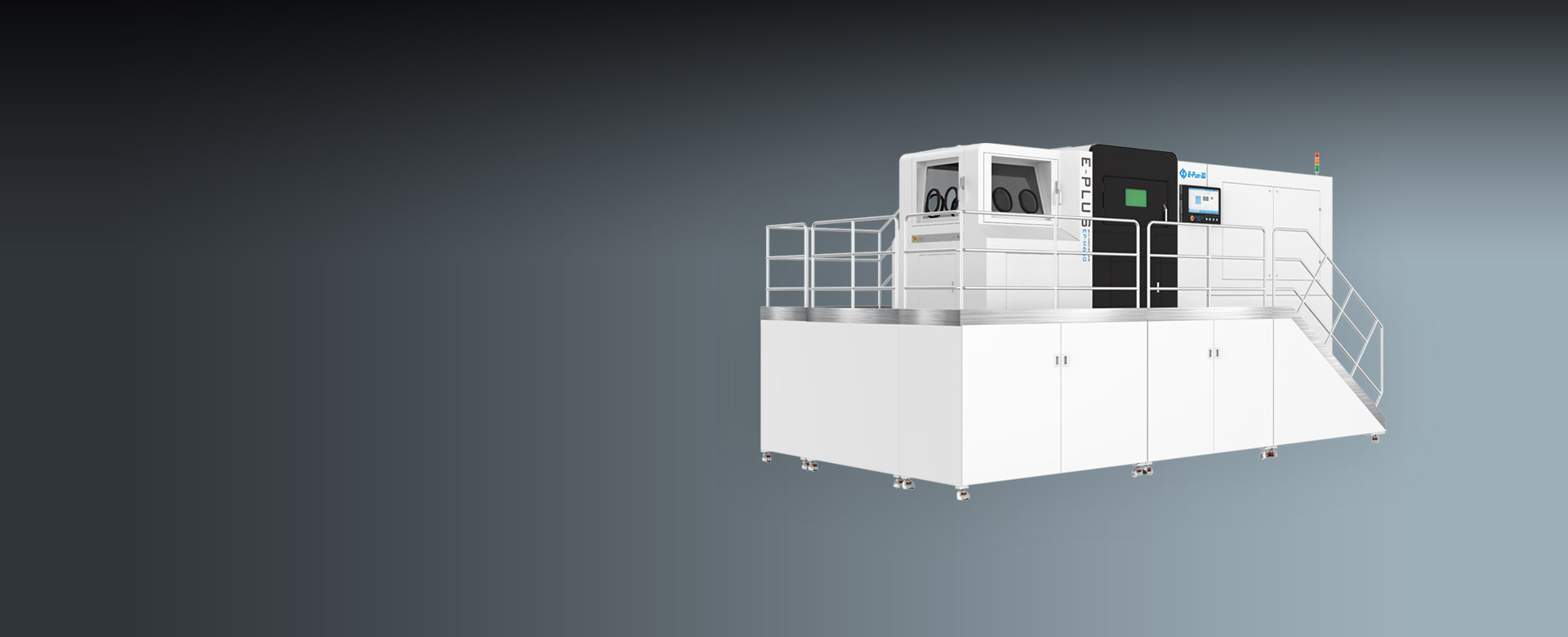

Additive Manufacturing Machine

Renowned as one of the preeminent 3D printing machine manufacturersin China, Eplus3D specializes in a diverse range of industrial 3D printing machines. We offers industrial 3D printing systems that can be flexibly integrated into existing production environments, equipped with a wide range of different building volumes, powerful multi-laser options, and advanced in-build monitoring and scanning system. Eplus3D's industrial 3d printing machinerymanufacture high-quality parts with excellent mechanical performance and accuracy.

Additive Manufacturing Machines 3DPrinting Machine Industrialfor Sale

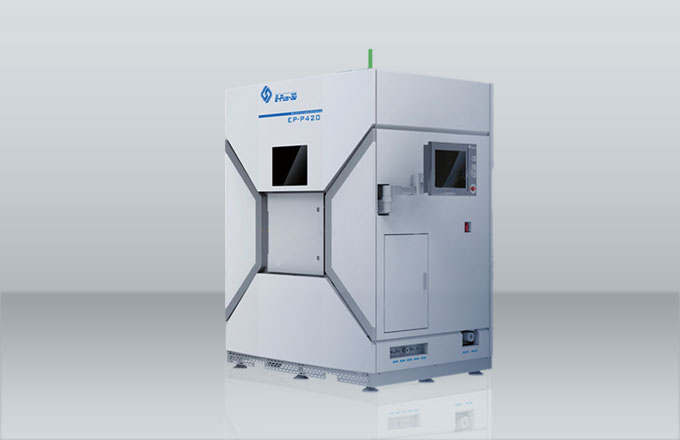

SLM3DMetal Printer

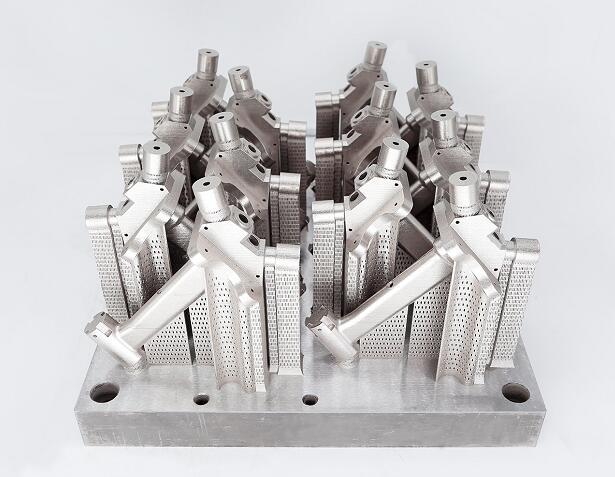

Eplus3D's industrial metal additive manufacturing machines use micron grades metal powder Stainless steel, Titanium alloy, Aluminum alloy, Nickel base alloy, Maraging steel, CoCr alloy, Copper alloy and other micron grades metal powder to manufacture the direct use metal parts, such as fuel nozzle, turbine blades, light-weight parts, conformal cooling channel parts, heat radiator, condenser, hydraulic components, light weight parts, metal molds, medical instruments, dental crown and implant.

SLS 3D Printer

Direct manufacturing plastic function parts with nylon, nylon composite, PS, PP, TPU and other micron grades plastic powder, which is used for rapid nylon parts, elastic parts, wax pattern, sand mold, fixtures, and other engineer plastic parts production. Eplus3D PPBF™(Polymer Powder Bed Fusion) technology is widely used in various industries such as automotive, electronics, machinery, aerospace, shoes, sports, packing, medical, etc.

SLA 3D Printer

Eplus3D Stereolithography 3D printers are industrial grade systems to create concept models, cosmetic prototypes, and complex parts with intricate geometries in as fast as in a few hours. A wide option with materials, extremely high feature resolutions, and quality surface finishes are possible with SLA technology.

What is the difference between CNC and additive manufacturing?

The main difference between 3D printing and CNC is that they work differently. 3D printing is an additive technology, while CNC is a subtractive technology. As we all know, metal 3d printingis easier to use than CNC machining. When the file is ready, you only need to select the part orientation, fill and support as needed. Then start to print. There is no need for a supervisor to supervise the whole process of printing. However, CNC is a labor-intensive process. It requires both skilled operators and different tools. It also requires complicated post-processing.

Why do we use additive manufacturing?

Additive manufacturing has the ability to reduce the time to produce complex prototypes. By applying additive manufacturing, products can be put into the market quickly by avoiding wasting valuable time waiting for changing tools or mold. For any changes or adjustments to the design, it can be made to the CAD file and programmed into the 3D printer in simple ways. 3D printers can also lower the time needed to manufacture fully functional products for use in operations. The process of additive manufacturing is additive, making it possible to manufacture products in a single step, without the need to produce different parts to be assembled later, thereby reducing production time.

Further, the additive approach can help in producing more rugged and sturdy equipment. This gives it a competitive edge over traditional manufacturing processes and also improves material use by reducing waste. Traditional manufacturing results in lots of waste that may not be correctly recycled, on the contrary, the only material that is consumed via additive manufacturing is the actual material used for the end product.

在线联系供应商

Other supplier products

| EP-M650 Metal 3D Printer | Using MPBF (Metal Powder Bed Fusion) technology, the EP-M650 is using a 657 x 657 x 800 mm³ build envelope and four laser systems to ensure a ... | |

| Eplus3D Metal Additive Manufacturing | Machines & Materials For Your Metal 3D Printing Demands Eplus3D metal printers are a lab from entry-level models to multi-layer machines for a... | |

| Additive Manufacturing Metal Material | Eplus3D metal printers are available from entry-level models to muti-laser machines for additive production at industrial grades. We also provide a... | |

| EP-M300 Metal 3D Printer | EP-M300 is a marvelous industrial metal 3d printerthat makes the production of reliable and high-quality large metallic parts viable on an industri... | |

| EPLUS 3D Additive Manufacturing Materials | Additive Manufacturing With SH8900H SH8900H is an ideal material for many industries, including Molding. The powder has been tested for use on ... |

Same products

| Waste Aluminum Plastic Pyrolysis Plant | 卖方: Shangqiu Sihai Energy Technology Co.,Ltd | Waste Aluminum Plastic Pyrolysis Plant The refining of waste aluminum and plastic mainly uses a ... | |

| Continuous Tire/ Rubber Powder Pyrolysis Plant | 卖方: Shangqiu Sihai Energy Technology Co.,Ltd | Continuous Tire/ Rubber Powder Pyrolysis Plant Pyrolysis is the process of heating organic mater... | |

| Herbicide Supplier | 卖方: HEBEI LAIKE BIOTECH CO.LTD | Herbicide Supplier Wholesale Herbicide Suppliers - Laike Biotech is a professional supplier ... | |

| Press Fit Machine | 卖方: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Press Fit Machine Mainly used in the semiconductor packaging industry, it can be used for variou... | |

| Tri-Temperature Test Product | 卖方: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Tri-Temperature Test Product Mainly used in the semiconductor packaging industry, it can be used... |