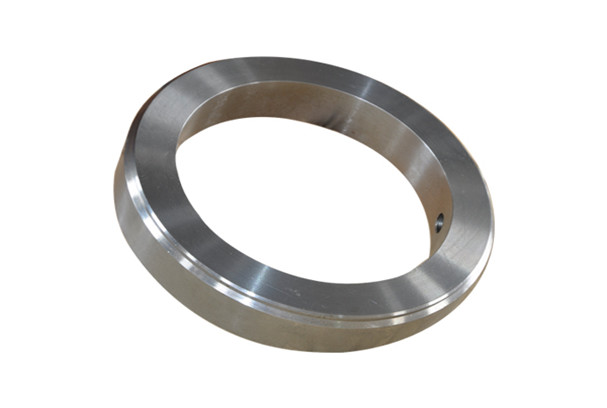

CASTING

Casting is one of the basic processes of modern equipment manufacturing. The casting process can be divided into three basic steps, namely casting metal preparation, mold preparation, and vacuum pressure castingprocessing. Casting metal refers to the metal material used for casting castings in the production of castings. It is an alloy in which metal elements are the main components and other metals or non-metal elements are added. It is usually called casting alloy, which mainly includes cast iron, cast steel, and cast non-ferrous alloy.

As one of the professional titanium casting companies, ECTN provides our clients with advanced metal casting services such as high pressure aluminum castingand low pressure aluminum casting, custom aluminum casting, custom brass casting, permanent mold aluminum casting and etc.

As a common catrgory of advanced metal casting, gravity mold casting is an ideal choice for the production of various complex aluminum castings of automotive parts.

Advantage of Casting

It Can Produce Parts With Complex Shapes, Especially Blanks With Complex Cavitie

Wide Adaptability, Metal Materials Commonly Used In Industry Can Be Cast, From A Few Grams To Hundreds Of Tons.

Wide Adaptability, Metal Materials Commonly Used In Industry Can Be Cast, From A Few Grams To Hundreds Of Tons.

The Shape And Size Of The Casting Are Very Close To That Of The Parts, Reducing The Amount Of Cutting, Which Is Non-cutting.

The Shape And Size Of The Casting Are Very Close To That Of The Parts, Reducing The Amount Of Cutting, Which Is Non-cutting.

It is Widely Used

40%~70% of agricultural machinery and 70%~80% of machine tools are castings.

Casting FAQs

Casting Cracks

The solution: Use low-strength investment materials, reduce the casting temperature of the metal as much as possible, and do not use alloys with low ductility and brittleness.

Easy To Crack When Die-casting Thin-walled Products

If this problem occurs, it may be due to material problems or poor mold opening or improper selection of process parameters. Try to control the proportion of waste not to exceed 30%. The mold retention time should not be too long, about 3s per mm of wall thickness, and ejection delay is not allowed. Long, generally 0.5-2s.

Metal Splashing During Die Casting

Reinstall the mold; increase the clamping force and adjust the sand casting and die castingmachine to keep the movable and fixed mold mounting plates parallel to each other; add a support plate on the movable mold to increase the rigidity of the sleeve plate.

Why Can't The Inner Processing Of Aluminum Die-casting Hole Exceed 0.25mm

In order to be suitable for die casting, people add a lot of silicon to the aluminum alloy used for die casting. When the aluminum alloy condenses in the mold, the silicon will float on the surface to form a layer of silicon film that is very hard and wear-resistant. Some OEM designers use this feature to directly design the inner surface of the die casting hole as a bearing surface. This silicon surface layer is generally only 0.2 to 0.9 mm thick. With too much processing, the life of the bearing surface will be shortened.

Unclear Marking During Casting

- Another factor that is easily overlooked is the casting location of the casting mark. When determining the casting position, try to keep the casting mark on the bottom or side to avoid being on the top surface.

If you want to know more about aluminium casting price, please contact us.

As a leading China CNCmanufacturingcompany in China, ETCN offers precision CNCmachining Chinaand manufacturing services covering different fields in China CNC grinding services like iron metal casting services, CNC machining (including plastic) services, CNC milling services, CNC punching services and CNC turning services.

在线联系供应商

Other supplier products

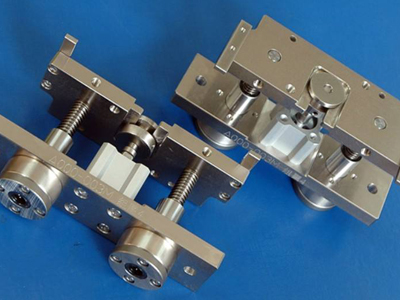

| Automations and Fixtures With CNC Machining | As a professional auto CNC machining ltdcompany, we can supply a high-quality level of CNC automation solutionand parts for the production of all-i... | |

| Casting | Casting is one of the basic processes of modern equipment manufacturing. The casting process can be divided into three basic steps, namely casting ... | |

| CNC Milling | CNC milling processing is suitable for precision and complex parts processing, periodically repeated production parts processing, multi-station, mu... | |

| Die Casting | Die Casting As a professional aluminum die casting co inc, ETCN provides our clients qualified mould die castingservice. The product uses a die-ca... | |

| CNC Grinding | After CNC milling or CNC turning forming, the surface roughness and behavior tolerance requirements of products are completed by cnc grinding, and ... |

Same products

| XD-MAX Winch for Drone | 卖方: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-MAX Winch for Drone The XD-MAX Winch for Droneis a high-performance aerial lifting solution d... | |

| XD-55 Winch for Drone | 卖方: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-55 Winch for Drone Introducing the XD-55 Winch for Drone—an advanced lifting system eng... | |

| XD-10 Winch for Drone | 卖方: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-10 Winch for Drone SAFE, EFFICIENT AND CONVENIENT.Your reliable and intelligent air transport... | |

| Uratech ER16 Collet Rack – CNC Collet Storage for ER, DR & RD 16 Series | 卖方: Uratech USA Inc | TheUratech ER16 collet rackis a premium storage solution designed for CNC shops, toolrooms, and m... | |

| Uratech Tool scoot cart for 50 taper tool holders | 卖方: Uratech USA Inc | Maximize efficiency in your machining operations with our50 taper CNC tool carts, the ultimate so... |