Precision Mmedical Swiss Machining

Precision Medical Swiss Machining

Medical manufacturing refers to the production and distribution of cnc machining medical devices, equipment, and supplies used in the healthcare industry. It involves a complex process that includes the design, development, testing, and production of medical products. This includes a wide range of products such as surgical instruments, prosthetics, diagnostic equipment, imaging systems, and drug delivery systems.

At Falcon Swiss Machine Shop, One of the key advantages of Swiss machining is its ability to produce parts with high accuracy and consistency. This is especially important in medical manufacturing, where precision is critical to ensure the safety and efficacy of medical devices.

4 Main Ways of Medical Device Machiningat Falcon

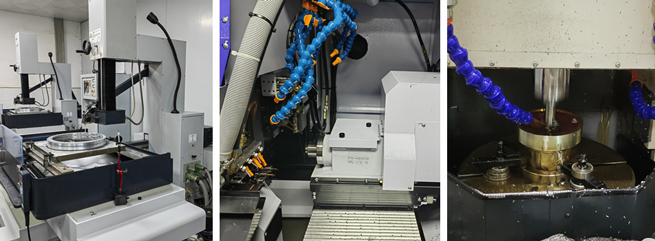

Falcon 5-axis machining process is particularly suited for the machining of high-accuracy, intricate geometries and can significantly improve processing efficiency and reduce processing time. Five-axis machining has wide applications in industries such as aerospace, automotive, medical, and defense.

Swiss machining technique is particularly suited for long and slender parts for medical devices. Our CNC Swiss machining service can maintain exceptional precision and repeatability, making it ideal for high-volume production runs that require consistent quality and accuracy for the medical industry.

Micro machining service is a critical process in the production of miniature components used in medical applications. It involves the use of precision tools and machines to create small parts with intricate geometries and tight tolerances.

Sinker electrical discharge machining (EDM) and wire EDM (WEDM) are advanced machining processes that utilize electrical discharges to remove material from workpieces. Sinker EDM is ideal for producing complex shapes with sharp internal angles and deep ribs, making it well-suited for the fabrication of high-precision medical components.

Falcon Capacities of Medical Parts Machining & Manufacturing

(1) 300+ Equipment: Falcon has 300 + production and testing equipment: mainly CNC lathes, machining centers (including not limited to Japan TSUGAMI, Taiwan King, etc.), traditional turning and milling, welding, internal and external grinding, surface grinder and EDM (mid-running and slow-running wire); Testing equipment includes spectrograph (ROHS), OES, CMM, projector, altimeter, height gause, etc.

(2) Accuracy: The general accuracy our machine can control is ±0.01mm, and the limit accuracy is ±0.001mm. Precision machiningmodule in the range of 0.3-15, size 0-1000mm, DIN 5-9 accuracy.

(3) Processing Capacity: Falcon has accumulated a lot of project experience in mass processing. We can produce at least 1,000,000 pieces in one month, providing one-stop service from one-off prototypes to millions of units for customers in all industries.

(4) Surface treatment: Falcon has at least 30 types of surface treatments. We can meet the specific types of surface treatment requirements of medical customers, such as corrosion protection, rust prevention, etc. Commonly processed surface treatments include anodization, plating, polishing, etc.

4 Keys about Falcon of Medical Manufacturing Quality and Assurance

5 Typical Medical Device CNCMachining MedicalParts That We Make

Our CNC technologies such as Swiss machining is a versatile and reliable process that can produce a wide range of medical parts with high precision and accuracy, making it an important tool for medical device manufacturers.

High-precision surgical instruments with tight tolerances and intricate shapes.

Precise and durable orthopedic implants, such as screws, plates, and pins.

Complex shapes and tight tolerances dental implants.

High-precision connectors for medical devices, such as catheters and IV lines.

Electronic components for medical devices such as sensors and housings.

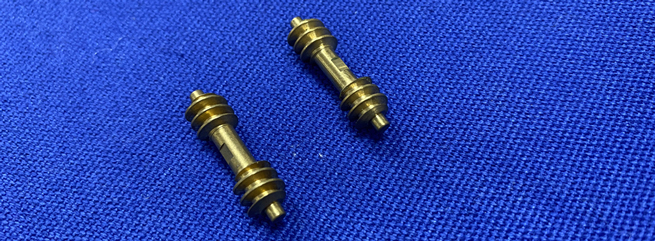

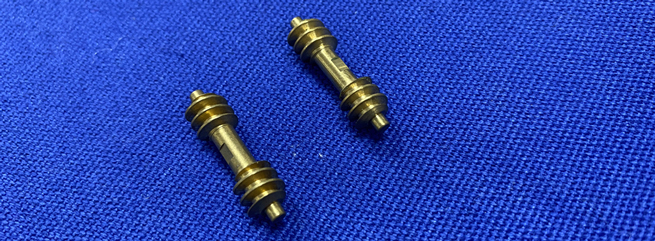

Case Study of Swiss Machined Medical Bone Screws

Bone screws: As an essential component in orthopedic treatments, metal screws need to be placed inside the human body for a long time. Their accuracy and sterile properties are important factors in the success of surgeries. Falcon has strict control over the raw materials of bone screws - titanium alloy/stainless steel. They must be inspected by a spectrometer to ensure their authenticity and qualified composition.

This Bone Screws for Medical are made by Swiss machining process, the process is:

Swiss turn machining

Polishing

Clean

Plating

Suggested Materials When Choose Swiss Turning for Medical Industry

When choosing materials for medical parts made by Swiss turning, it is important to consider factors such as biocompatibility, durability, and corrosion resistance. It is also important to work with a skilled and experienced Swiss machining company that has the expertise to produce high-quality medical parts that meet your specific requirements.

There are several materials that are commonly used. Some of these materials include:

Falcon's commitment to quality, innovation, and customer satisfaction has helped us build a reputation as a trustworthy and reliable machining medical partssupplier. We strive to continually improve our manufacturing processes and technology to stay at the forefront of the precision medical machiningindustry. Partnering with Falcon ensures the production of top-quality medical devices, instruments, and equipment that meet the stringent standards of the healthcare industry. Share your project.

在线联系供应商

Other supplier products

| Aluminum Precision Machining Services | Aluminum CNC Services Aluminum is a popular material for Swiss machining due to its excellent strength-to-weight ratio, corrosion resistance, and ... | |

| Precision Titanium Machining | Precision Titanium Machining Why is Titanium So Hard to Machine? Titanium, as a challenging material, has a unique combination of properties in... | |

| Brass and Copper Precision Machining | Is Brass Easier to Machine than Copper? Copper is a soft, malleable metal that is an excellent conductor of electricity and heat, which makes it s... | |

| Brass and Copper Precision Machining Services | Brass and Copper MachiningServices Is Brass Easier to Machine than Copper? Copper is a soft, malleable metal that is an excellent conductor of ... | |

| Precision Mmedical Swiss Machining | Precision Medical Swiss Machining Medical manufacturing refers to the production and distribution of cnc machining medical devices, equipment, and... |

Same products

| Windshield Wiper Blades | 卖方: Guangzhou May Import & Export Trading Co.,Ltd | Because of legal requirements, almost everywhere cars must be equipped with windshield wiper cutt... | |

| 3000W MODIFIED SINE WAVE INVERTER | 卖方: Suzhou Cosuper Energy Technology Co., Ltd | The Cosuper DPI3000 modified sine wave inverter converts 12V/24V battery power into 120V/230V AC ... | |

| Precision Mmedical Swiss Machining | 卖方: Falcon MFG Co .,Ltd | Precision Medical Swiss Machining Medical manufacturing refers to the production and distributio... | |

| car camera car monitor | 卖方: 广州市易达电子科技有限公司 | For car cameras ,we have got many popular models ,like the turtle camera ET-388,butterfly car cam... | |

| Car reversing camera | 卖方: Helen wang | Dia= 16.5 mm , Butterfly and bracket for choice , cap with black / white / grey / gun silver for ... |