Flange Molding

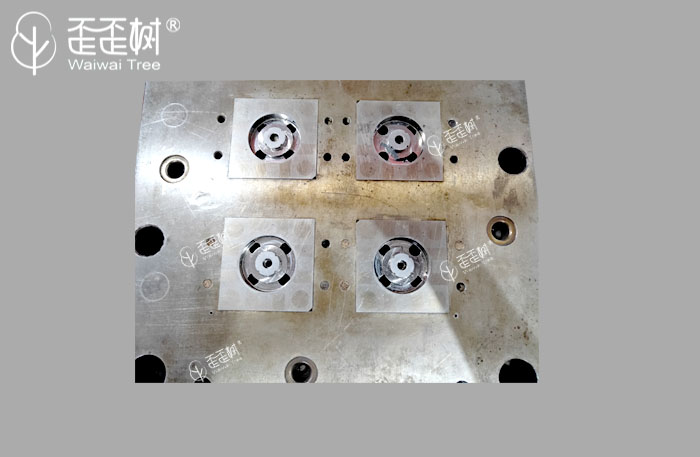

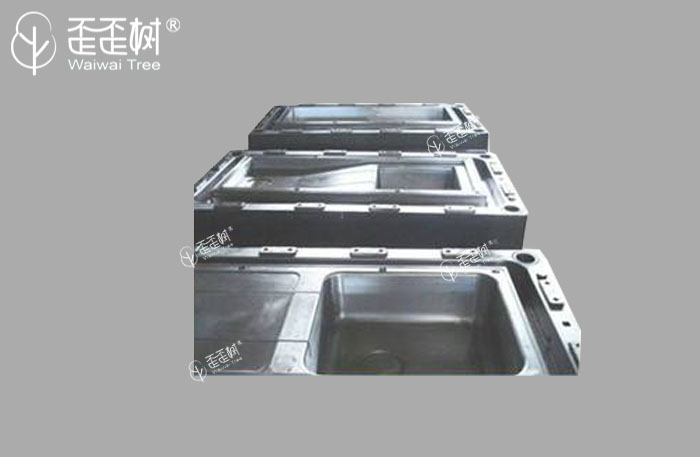

Mainly for injection molding, the cavity pressure should be considered as small as possible when designing the runner and the parting surface. Since the BMC material cannot be decomposed, we are the first to use the materialless handle structure in China. Vacuuming structure, the mold temperature balance is consistent. The appearance and strength of the product are guaranteed.

High insulation, high temperature resistance and high strength. The mold has a high degree of standardization, reasonable flow channel design, small cavity pressure, balanced temperature, no handle, and low power consumption.

You can know more about flange moldingfrom us.

Aobang technology limitedhas a technical team engaged in many years of production and R&D, and has the industry-leading expertise and technical level. We are dedicated to meeting the needs of our customers and highlighting the value that is given to our customers.To learn more about bulk molding compound manufacturing, please contact us!

在线联系供应商

Other supplier products

| SMC/BMC Antenna Reflector | High precision, high efficiency, and high gain The most important job of usingsmc bmcfor the manufacture of antennas is to fully exploit its fea... | |

| BMC/SMC Molded Products | BMCSMCthermosetting plastic products are produced by SMC and BMCmoldingprocess. PRODUCTS Types of BMC/SMC Molded Products BMC/SMC Motor SMC/B... | |

| Household Mould | Household Mould Description Mainly for pressure molding, the cavity pressure should be considered as small as possible when designing the partin... | |

| BMC/SMC Molded Products | What Is SMC Plastic? SMC, BMC thermosetting plastic products are produced by BMC SMCplastic molding process. BMC/SMC Motor Plastic SMC/BMC e... | |

| SMC/BMC Antenna Reflector | High precision, high efficiency, and high gain The most important job of using bmc reflectorfor the manufacture of antennas is to fully exploit it... |

Same products

| 真空泵三相异步电机 | 卖方: Taizhou Sulin Electromechanical Co., Ltd. | 真空泵三相异步电机是一种专为真空泵设计的专用电机,具有高效可靠的特点。该电机是各种工业应用中的关键部件,尤其是在真空技术至关重要的领域。其坚固耐用的设计和卓越的性能使其成为需要持续高效产生真空的... | |

| IndustrialFlex Worm Gear Motor | 卖方: Ruian Zhanpeng Machinery Co., Ltd | IndustrialFlex Worm Gear Motoris built to support equipment requiring smooth motion transmission ... | |

| TorqueBalance High Precision Gear Reducer Motor | 卖方: Ruian Zhanpeng Machinery Co., Ltd | TorqueBalance High Precision Gear Reducer Motorprovides controlled speed output and flexible redu... | |

| High Precision Gear Reducer Motor | 卖方: Ruian Zhanpeng Machinery Co., Ltd | The High Precision Gear Reducer Motoris an advanced power transmission solution that combines a h... | |

| Philips TTF Motor 9498 396 00197 | 卖方: KF-SMT Technology Co., Ltd | Part Name: PHILIPS TTF MOTORPart NO: 9498 396 00197 Delivery 1-5working days ... |