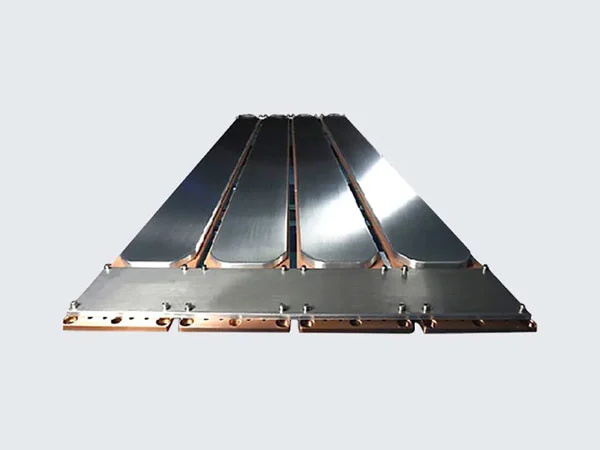

Copper Target

Copper targetis a high-purity and highly conductive material utilized in various applications such as semiconductor production, solar cell manufacturing, and research applications such as X-ray fluorescence analysis. The copper targets are available in various shapes and sizes and are designed with high precision to meet the industry standards. The copper targets feature exceptional durability, excellent thermal conductivity, and resistance to corrosion and oxidation, making them a reliable material.

Classification Of Copper Target

Copper targets are classified based on the manufacturing process, purity level, and the shape and size of the final product. Based on the manufacturing process, the copper targets are divided into two categories - sputtering targets and electroplating targets. Sputtering targets are manufactured using high-temperature techniques, whereas electroplating targets are made through electrochemical processes.

Purity level also plays a significant role in copper target classification, with high-purity copper targets typically featuring purity levels greater than 99.99%. Depending on the shape and size requirement, copper targets can be classified into various shapes such as plates, disks, squares, and rectangles, or custom shapes as per the specific application needs.

Operating Principle of Copper Target

Copper targets are primarily used in sputtering and electroplating applications, where high-purity copper films are required. In the sputtering process, a high-energy ion beam hits the surface of the copper target, causing it to eject copper atoms. These atoms then deposit onto a substrate, forming a thin film.

The sputtering process operates based on the ionization of the sputtering gas, typically argon, which creates a plasma that is accelerated towards the target surface. The plasma ionizes the gaseous argon, creating high-energy ions that impact the copper target, causing sputtering. The sputtered material is deposited onto a substrate, creating a uniform and high-purity copper film.

In the electroplating process, a copper target is used as the anode, and a substrate is used as the cathode. Direct current is passed through a copper sulfate solution to deposit copper onto the substrate. During this process, copper ions dissolve off the target, migrate to the cathode, and deposit onto the substrate, forming a thin copper film.

Overall, the efficient operation of both sputtering and electroplating processes is highly dependent on the purity and quality of the copper target material.

Physical Properties Of Copper Target

|

Density |

|

|

Color |

Purplish red |

|

Melting point |

|

|

Boiling point |

2567℃ |

The copper target is appropriate for various sputtering techniques, such as two-pole sputtering, three-pole sputtering, four-pole sputtering, RF sputtering, ion beam sputtering, magnetron sputtering, and facing targets sputtering. It is suitable for the deposition of several types of films, such as reflective, conductive, semiconductor, decorative, protective, and integrated circuit films, commonly used in applications including displays.

Compared to other target materials, copper targets are cost-effective, making them the preferred choice when the desired film functionalities can be achieved.

If you want to know more about copper target price, please contact us.

More applications of cooling system in industry, please visit our website.

在线联系供应商

Other supplier products

| Molybdenum Target | The requirements for molybdenum targets are significantly more stringent than those of conventional material industries. These requirements entai... | |

| Molybdenum Sheet | Molybdenum sheetis a thin, flat piece of metal made from molybdenum. It is known for its high melting point, resistance to corrosion and wear under... | |

| Molybdenum Wire | Molybdenum wireis a thin, high-strength wire made from molybdenum metal. It is known for its excellent thermal and electrical conductivity, high me... | |

| Molybdenum Screw. | Molybdenum screwis a fastener made of molybdenum, a refractory metal with excellent strength, corrosion resistance, and thermal stability. Molybden... | |

| Molybdenum Plate | Molybdenum plateis a high-quality, durable, and lightweight material used in a variety of applications, including aerospace, manufacturing, and def... |

Same products

| Yoyik offer cooler GLC2-2.6 for steam turbine | 卖方: DONGFANG YOYIK (DEYANG) ENGNIEERING CO; LTD | "Yoyik offer cooler GLC2-2.6 for steam turbine YOYIK is a hi-tech company specializing in the pro... | |

| Recirculated Air Heating and Cooling Unit | 卖方: Fujian Air Technology Systems Co., Ltd | When hot/cold water or stream passes the Recirculated Air Heating and Cooling Unit, the efficient... | |

| Water Chiller Manufacturers Near Me | 卖方: Shanghai Kendall Refrigeration Equipment Co., Ltd | Headquartered in Shanghai, China, Kendall stands as a pioneer and leader in the refrigerati... | |

| Cold Room Solutions | 卖方: Shanghai Kendall Refrigeration Equipment Co., Ltd | At , we bring over 20 years of expertise in refrigeration design, construction, installatio... | |

| Flooded Water-cooled Screw Chillers | 卖方: Shanghai Kendall Refrigeration Equipment Co., Ltd | This has a compact structure which makes it easy to install and maintain. It is equipped wi... |