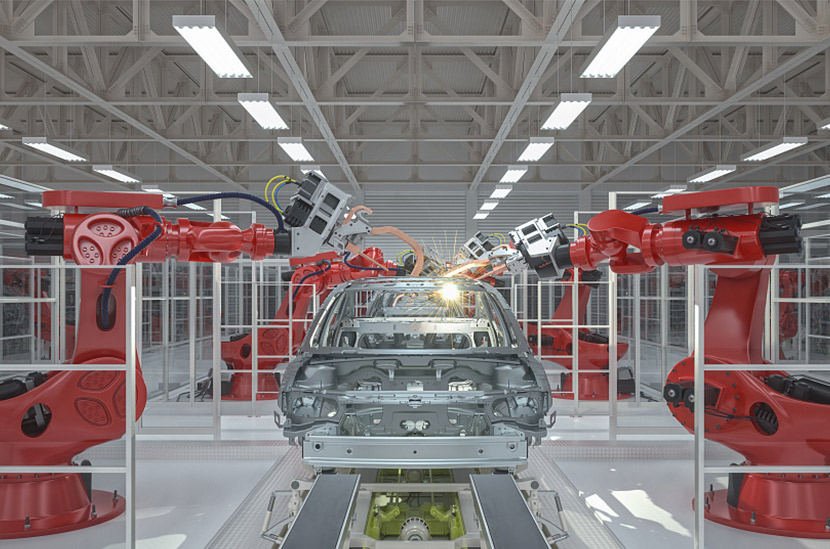

FRICTION STIR WELDING IN AUTOMOTIVE INDUSTRY

FRICTION STIR WELDING IN AUTOMOTIVE INDUSTRY

The development of new energy vehicles in the world started with hybrid power, and then gradually entered the era of battery-based vehicles. Pure electric and plug-in hybrids have become the main policy support for new energy. Since 2013, new energy vehicles have developed rapidly with the promotion of support policies from various countries. In 2021, the global sales of new energy passenger vehicles including pure electric, plug-in hybrid, and fuel cell vehicles will be 6.23 million, a year-on-year increase of 118.6%. China has put forward the strategy of "energy-saving and new energy vehicles", and pays great attention to the research and development and industrialization of new energy vehicles. Under the premise of advocating global environmental protection today, the new energy vehicle industry will definitely become the orientation and goal of the future development of the automotive industry.

BATTERY TRAY FOR ELECTRIC VEHICLE

The aluminium alloy battery tray/ lower box of the battery pack is mainly made of steel and aluminium alloy. Aluminium alloy is favored by more and more automobile OEMs and manufacturers around the world because of its low density and various forming processes, which can meet the requirements of electric vehicle lightweight. At present, the aluminium alloy battery tray has two process schemes: integral casting and aluminium profile welding. Friction stir welding and process has been widely used in the manufacture of battery trays because of its non-melting, automation, intelligence, environment-friendly and integrated characteristics.

COLD ALUMINIUM PLATE

The main materials of friction stir welding water-cooled plates are aluminium alloy and stainless steel. Aluminium alloy can meet the lightweight requirements of the application end due to its low density and various forming processes.

CASING WITH FRICTION STIR WELDING FSW COOLING/COLD CHANNEL

The main processes of aluminium alloy motor shells include aluminium extrusion forming and friction stir welding.

There are many custom die casting manufacturers, but we are one of the best choices for you.

在线联系供应商

Other supplier products

| Carbon Nanotube Sheets | Carbon nanotubes have good flexibility, excellent electrical and thermal conductivity, and are seamless, hollow tubes formed by cnt sheetsformed by... | |

| FRICTION STIR WELDING IN AUTOMOTIVE INDUSTRY | FRICTION STIR WELDING IN AUTOMOTIVE INDUSTRY The development of new energy vehicles in the world started with hybrid power, and then gradually e... | |

| Die Casting Lighting | Ningbo Cheeven New Materials is one of the China Led FSW Manufacturers and die casting lighting factory.We have a team of die casting lightingto de... | |

| Die Casting Automotive Parts | With the adding number of vehicles on our roads, it has become more critical than ever to reduce weight to increase energy effectiveness and reduce... | |

| Die Casting Automotive Parts | In the early stage of product development, the customer only needs to provide 2 D or 3 D renderings or samples in the format of DXF/DWG/PRT/SATIGES... |

Same products

| Common Rail Fuel Injector Nozzle DLLA150P1746 | 卖方: China Lutong Part Plant | Common Rail Fuel Injector Nozzle DLLA150P1746 Tina #for Bosch 0 281 006 074 Pressure Control Val... | |

| Automotive Parts & Accessories | 卖方: O&K GROUP LIMITED | Okwishing supplies all kinds of Automotive Parts & Accessories Okwishing () is a cross-borde... | |

| OEM 23390-0L041 Auto Fuel Systems for Toyota | 卖方: Foshan Bohua Auto Parts Co., Ltd | OEM 23390-0L041 Auto Fuel Systemsfor Toyota The fuel filter is used to prevent particles, water ... | |

| OEM Car Engine Timing Belt for Hyundai | 卖方: Foshan Bohua Auto Parts Co., Ltd | The OEM car engine timing beltis a genuine Hyundai part designed specifically for Hyundai vehicl... | |

| OEM Car Fuel Filter for Toyota | 卖方: Foshan Bohua Auto Parts Co., Ltd | The fuel filter is used to prevent particles, water and impurities in the fuel, and ensure that t... |