13X Molecular Sieve

13X Molecular Sieve is the sodium form of the type X crystal and has a much larger pore opening than the type A crystals. 13X Molecular Sieve will adsorb molecules with a kinetic diameter of less than 9 Angstrom (0.9 nm) and exclude those larger.

13X molecular sieve material also has the highest theoretical capacity of the common adsorbents and very good mass transfer rates. Molecular sieve 13x provided by NAIKE CHEMICAL, one of the professional zeolite 13x suppliers in China, can remove impurities too large to fit into a type A crystal and is commonly used to separate nitrogen from oxygen.

Molecular Sieve 13x Types

Industrial desiccant category: Mainly used for the use of equipment desiccant package, deep drying of air compressor dryer, commonly used type of 3A molecular sieve, commonly used specification is 3-5mm, the main type of insulating glass process is 3A molecular sieve, the main specification is 1.5-2.5mm size.

Molecular sieve for oxygen production: Molecular sieve is a good choice for oxygen production. The concentration of oxygen production is 93-96%. According to different indicators of the equipment, the molecular sieve for oxygen production is usually a 13X type molecular sieve with a conventional size of 1.6-2.5mm.

Type of air separation equipment: Air separation equipment, which mainly separates rare gases in the air, such as helium, nitrogen, argon and so on. The commonly used type is 13x molecular sieve with a specification of 1.6x-2.5mm.

13X-HP molecular sieve: A new type of X zeolite molecular sieve, a special molecular sieve for oxygen production. The principle of oxygen production: the air is absorbed by the compressor to absorb the air, and the air is extracted into the 13X-HP molecular sieve. The 13x zeolitemolecular sieve absorbs nitrogen, carbon dioxide and other waste gases in the air, and only oxygen is left into the gas collecting bottle. The zeolite 13xoxygen is purified by the high pressure valve, and the oxygen is output after raising the concentration of the oxygen making machine to the standard.

How do Molecular Sieves 13x Remove Water?

13x molecular sieve adsorbs water, can make the gas dry very quickly. According to the research, in the molecular sieve desulfurization, because the molecular sieve has a very strong adsorption capacity to water and other polar small molecules, therefore, the LPG mercaptan removal process must strictly control the water content. Due to the limitation of LPG mercaptan removal, it is widely used in Europe and the United States, and there is also a preliminary application in China.

13x molecular sieve is used as a solid adsorbent in the chemical industry, the substance adsorbed by 13x molecular sieve can be desorbed, and the carbon molecular sieve adsorbent can be regenerated. At the same time, molecular sieves are also used for the drying, separation, purification and recovery of gases and liquids. In the oil company industry, a modified X-type or Y-type molecular sieve exchanged by high valence metal cations, such as lanthanum, mixed light rare earth elements and cerium, is physically adsorbed to remove organic sulfides from liquefied petroleum gas. in this way, the gas can be dried very quickly to meet the needs of the company.

Molecular Sieve 13x/zeolite 13x Uses

As a polar adsorbent material, molecular sieve has very strong hydrophilic properties and is a very excellent material for dewatering and drying. The pore size of 13X molecular sieves is larger than that of A-type molecular sieves, resulting in stronger and more water absorption properties.

The molecular sieves produced by Naike Chemical are produced through the whole process of closed automated equipment, which can achieve a lower water content than the industry, better than the national standard water adsorption capacity, and have a very strong water absorption capacity at room temperature and pressure.

13x molecular sieve drying and dehydration, mainly used in various types of air dryers, serving a variety of high water content requirements of the industry. In the oil industry, natural gas industry and liquid hydrocarbon drying treatment can be used as molecular sieve adsorption dehydration treatment.

13x molecular sieve can dry the gas very quickly because the molecular sieve has a strong adsorption capacity for water and carbon dioxide, which deeply meets the special needs of the deep cooling air-separation industry. 13x molecular sieve absorbs water to dry the gas very quickly because it is a kind of synthetic zeolite. The characteristic of selectivity of adsorption is that H2S and organic sulphur can be removed to a lower level at the same time. It is characterized by physical adsorption and no chemical reaction.

13x molecular sieve, also known as zeolite and 13x molecular sieve zeolite, is a kind of crystalline aluminosilicate with regular and uniform pores in its crystal place structure. It is the best adsorbent for sweetening. The molecular sieve method has the advantages of no caustic prescrub, no pollution, and can be adsorbed at room temperature. At the same time, because it can only be regenerated at about 300C, it will need to increase the input cost of the company. Because the pore size of the molecular sieve is of the order of magnitude of molecular size, it only allows molecules with a smaller diameter than pore size to enter, so the molecules in the mixture can be screened according to size, and then the best quality products can be obtained.

Note: Zeolite 13x powder should not adsorb organic gases or liquids before use, otherwise 13x molecular sieve need to be regeneration.

For more information about zeolite 13x priceand zeolite 13x pore size, please feel free to contact us!

在线联系供应商

Other supplier products

| Carbon Molecular Sieve | PSA (pressure swing adsorption) nitrogen generation is implemented by the selective adsorb characteristic of CMS, and different adsorption capaciti... | |

| PSA MOLECULAR SIEVE | psa molecular sieve zeolite molecular sieve oxygen generator/ molecular sieve oxygen generator zeolite oxygen generator molecular sieve oxygen c... | |

| CERAMIC BALL | The ceramic balls produced by our company are mainly divided into the following categories: Inert alumina balls Activated alumina ceramic balls Gr... | |

| Fenske Spiral | Fenske Spiral The Fenske spiral Packingmade of wire and has a shape similar to that of a spring, also known as a triangular spring Packing. Its ... | |

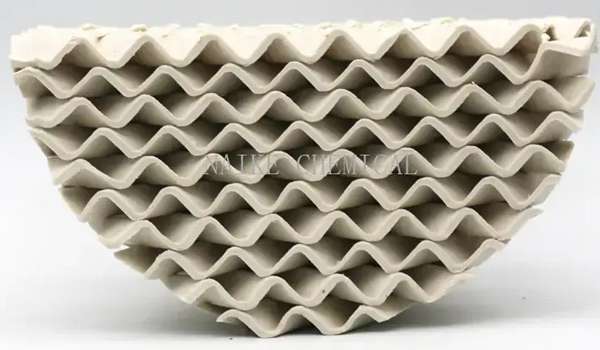

| CERAMIC STRUCTURED PACKING | Ceramic structured packingis made up of many packing unit bodies that share the same geometry shape. Corrugated ceramic packing is called Kelapak p... |

Same products

| Peptide Technology Cooperation & Transfer | 卖方: PeptiOrigin Biotechnology Co., Ltd. | Peptide Technology Cooperation & Transfer Driving Innovation Through Strategic Partnerships ... | |

| Recombinant Human Fibroblast Growth Factor-basic | 卖方: Hangzhou NeuroPeptide Biological Science and Technology Incorporation, Ltd | Physical Appearance:Freeze-dried powder Formulation:5mMPB(pH7.4) before freeze-drying TheorypI:... | |

| Recombinant Staphylococcal Protein A | 卖方: Hangzhou NeuroPeptide Biological Science and Technology Incorporation, Ltd | TheorypI:5.10 Resources:Escherichia coli(E. coli) Purity:≥95% Storage condition:-20℃ Stora... | |

| NuPerley Core 700 | 卖方: Hangzhou NeuroPeptide Biological Science and Technology Incorporation, Ltd | NuPerley Core 700 Matrix:Rigid agarose microsphere Ligand:n-octylamine Particle size, d50:~90 ... | |

| Q NUPharose Fast Flow | 卖方: Hangzhou NeuroPeptide Biological Science and Technology Incorporation, Ltd | Matrix:6% Cross-linked agarose Ligand:Quaternary ammonium salt, -CH2CH(OH)CH2N(CH3)3+ Particle ... |