Cellulose Ethers

Kima is a leading manufacturer of cellulose ether from China, and has been serving global cellulose ether market over ten years with our brand KimaCell®.

Kima offers a comprehensive range of cellulose ether products for sale to meet the requirement of global customers. KimaCell® is the unique trademark of our cellulose ether products, including 20000 tons of Hydroxypropyl Methyl Cellulose (HPMC), Hydroxyethyl Methylcellulose (HEMC),Hydroxyethyl Cellulose (HEC), Methyl Hydroxyethyl Cellulose (MHEC), Sodium Carboxymethyl Cellulose (CMC), Redispersible Polymer Powder(RDP), Methyl Cellulose (MC), Ethyl Cellulose (EC), Hydroxypropyl Cellulose (HPC), Hydroxypropyl Starch Ether (HPS), Microcrystalline Cellulose (MCC).

Nowadays Kima's different grade of cellulose ether have been sold to more than 20 countries around the world, successfully used in building & construction, pharmaceutical, food, detergent, paints & coatings, ceramics, PVC, home care, personal care, oil drilling, cosmetics etc. Quality is well accepted among customers. KimaCell® become the reliable brand in cellulose ether market.

Buy KimaCell® cellulose ether to make product in bulk, and get the competitive wholesale hydroxypropyl cellulose price. For more information like cellulose ether viscosity, grade and formula, price per kg, please feel free to contact us.

Cellulose Ether Products List

Hydroxypropyl Methylcellulose (HPMC)

Hydroxypropyl Methylcellulose (HPMC), also known as hypromellose and methyl cellulose wholesaleether derivatives, is made of highly pure cotton cellulose as raw material, which is specially etherified under alkaline conditions. KimaCell® HPMC is a non-ionic cellulose ether, white powder, odorless and tasteless, soluble in water and most polar organic solvents and swell into a transparent solution in both hot and cold water. The aqueous solution has surface activity, high transparency and stable performance. CAS 9004-65-3

Hydroxyethyl Cellulose (HEC)

Hydroxyethyl Cellulose (HEC) is a non-ionic water soluble cellulose ether, which is a white or off-white, odorless, non-toxic fibrous or powdery solid polymer produced by etherification reaction of alkaline cellulose and ethylene oxide. KimaCell® HEC has good properties of thickening, suspending, dispersing, emulsifying, bonding, film-forming, water retention and protective colloid, HEC has been widely used in paints & coatings, construction, oil drilling, pharmaceutical, food, textile, paper and polymer polymerization and other fields. CAS 9004-62-0

Hydroxyethyl Methyl Cellulose (HEMC)

Hydroxyethyl Methyl Cellulose(HEMC) is methyl cellulose ether derivatives. HEMC is prepared by adding ethylene oxide substituents (MS 0.3~0.4) to methyl cellulose (MC). Its salt resistance is better than that of unmodified polymers. KimaCell® HEMC plays an important role in drymix mortar industry which can increase good workability and good water retention, excellent open time, slip resistance, impact resistance, adhesion and shear strength. HEMC is widely used in various dry-mixed mortars such as tile adhesives, protective mortars, waterproof mortars, grouting materials, detergent etc. CAS 9032-42-2

Methyl Hydroxyethyl Cellulose (MHEC)

Methyl Hydroxyethyl Cellulose (MHEC) is a non-ionic cellulose ether that is easily soluble in both hot and cold water. Compared with other cellulose ethers, methyl cellulose derivatives have slight Newtonian flow characteristics and can provide relatively high shear viscosity. Methyl Hydroxyethyl cellulose (MHEC) has the characteristics of thickening, suspending, dispersing, bonding, emulsifying, film-forming, and water retention. The water retention, viscosity stability and mildew resistance, dispersibility of MHEC is stronger than hydroxypropyl methyl cellulose (HPMC). KimaCell® MHEC has Good anti-sagging effect, long open time, high early strength, high temperature adaptability, easy to stir, easy to operate when adding to drymix mortars. CAS 9032-42-2

Methyl Cellulose (MC)

Methyl Cellulose (MC) is a cellulose methyl ether which is White or light yellow or light gray small particles, filaments or powder. It is odorless and tasteless, and about 27%~32% of the hydroxyl groups exist in the form of methoxy groups. KimaCell® Methyl Cellulose MC can be used as synthetic resin dispersant, coating film-forming agent, thickener, adhesive for building materials, sizing agent for textile printing and dyeing, film-forming agent for pharmaceutical and food industries, etc. CAS 9004-67-5

Ethyl Cellulose (EC)

Ethyl Cellulose (EC), also named as cellulose ethyl ether, is a cellulose derivative in which ethoxy groups replace the hydroxyl groups, with different molecular weights and viscosity. KimaCell® Ethyl Cellulose is white granules or powder, odorless and tasteless; easily soluble in toluene or ether, soluble in dichloromethane, slightly soluble in ethyl acetate and methanol, insoluble in water, glycerol and propylene glycol; Ethyl Cellulose is stable, resistant to alkali and salt, and is more sensitive to acid than cellulose ester. CAS 9004-57-3.

Carboxymethyl Cellulose (CMC)

Carboxymethyl cellulose (CMC), known as cellulose gum, is a high polymer cellulose ether obtained by chemically modifying natural cellulose. Sodium CMC is white or milky white fibrous powder or granules, with a density of 0.5-0.7 g/cm3, almost odorless, tasteless, and hygroscopic. CMC is easily dispersed in water to form a transparent colloidal solution, CMC can be widely used in paints & coatings, food ingredients, paper-making additives, toothpaste, oil drilling, mud conditioners, ceramics, detergent etc. CAS 9004-32-4.

Redispersible Polymer Powder (RDP)

Redispersible Polymer Powder (RDP) are water-soluble redispersible latex powders, which are divided into ethylene/vinyl acetate copolymers, vinyl acetate/ethylene tertiary carbonate copolymers, acrylic acid copolymers, etc., and the powders made after spray drying are bonded agent, with polyvinyl alcohol as a protective colloid. KimaCell® RDP powder can quickly redisperse into emulsion after contacting with water. Due to the high bonding ability and unique properties of redispersible latex powder, such as: water resistance, construction and heat insulation, etc., RDP is widely used in tile adhesives, skimcoat, drymix mortar. CAS 24937-78-8

Hydroxypropyl Cellulose (HPC)

Hydroxypropyl Cellulose (HPC) is a non-ionic water-soluble cellulose ether obtained by the reaction of cellulose and propylene oxide. HPC is odorless, tasteless, usually white to pale yellow powder. Its unique physical properties and its solubility in water and various organic solvents make it widely used in tablet bonding, release regulation, film coating and rheology regulation. HPC has been used in the pharmaceutical industry for many years, and the county has very good safety. KimaCell®HPC products comply with the US Pharmacopoeia, European Pharmacopoeia, and Japanese Pharmacopoeia. CAS 9004-64-2.

Hydroxypropyl Starch Ether (HPS)

Hydroxypropyl starch ether (HPS) is a white colorless powder with good fluidity and good water solubility. Its aqueous solution is transparent and colorless with good stability. It is stable to acid and alkali, the gelatinization temperature is lower than that of native starch, and the change of cold and hot viscosity is more stable than that of native starch. Mixing with salt, sucrose, etc. has no effect on viscosity. After etherification, the ice-thaw stability and transparency are improved. CAS 9049-76-7

Cellulose Ether Manufacturing Process

Cellulose ethersare a group of important industrial materials derived from cellulose, a natural polymer found in the cell walls of plants. They are widely used in various applications such as adhesives, coatings, construction materials, pharmaceuticals, and food products. The manufacturing process of methocel cellulose etherinvolves several steps, including cellulose extraction, chemical modification, and purification. In this article, we will discuss the detailed process of cellulose ether manufacturing.

Cellulose Extraction:

The first step in the manufacturing process of cellulose ethers is the extraction of cellulose from a natural source. The most common source of cellulose is wood pulp, which is obtained from trees through a process called pulping. Wood chips are treated with chemicals, heat, and mechanical action to separate the cellulose fibers from other components like lignin and hemicellulose. The resulting pulp is then washed and bleached to remove impurities and achieve a high-purity cellulose material.

Alkali Treatment:

Once the cellulose pulp is obtained, it undergoes an alkali treatment to remove residual lignin and hemicellulose. In this step, the pulp is mixed with a hot alkali solution, usually sodium hydroxide (NaOH), and heated under controlled conditions. The alkali breaks down the lignin and hemicellulose, solubilizing them in the solution, while the cellulose remains intact.

Etherification:

The next step in the manufacturing process is the chemical modification of cellulose through etherification. Etherification involves introducing ether groups into the cellulose structure to enhance its solubility and other desired properties. Various types of ether groups can be introduced, such as methyl, ethyl, hydroxyethyl, hydroxypropyl, and carboxymethyl.

Alkali Cellulose Formation:

In this step, the alkali-treated cellulose pulp is converted into alkali cellulose by reacting it with an alkali metal hydroxide, usually sodium hydroxide (NaOH). The cellulose pulp is mixed with a solution of NaOH and heated, resulting in the dissolution of cellulose and the formation of alkali cellulose.

Etherification Reaction:

The alkali cellulose is then reacted with an appropriate etherifying agent to introduce the desired ether groups. The most commonly used etherifying agents are alkyl halides (e.g., methyl chloride, ethyl chloride) for alkyl ethers and alkylene oxides (e.g., ethylene oxide, propylene oxide) for hydroxyalkyl ethers. The reaction is typically carried out in the presence of a catalyst, such as tertiary amines or alkali metal hydroxides.

Neutralization and Washing:

After the etherification reaction, the reaction mixture is neutralized to deactivate the catalyst and adjust the pH. This is usually done by adding an acid, such as hydrochloric acid (HCl). The neutralized mixture is then washed with water to remove any unreacted reagents, by-products, and impurities.

Purification:

The purified cellulose ether is obtained by further processing the etherified product. Purification steps may include filtration, centrifugation, evaporation, and drying. These processes remove residual impurities, solvents, and excess reactants, resulting in a high-purity cellulose ether product.

Quality Control:

Throughout the manufacturing process, quality control measures are implemented to ensure the desired properties and performance of the cellulose ether. Parameters such as viscosity, degree of substitution, moisture content, and purity are carefully monitored using analytical techniques.

Packaging and Storage:

The final step in the cellulose ether manufacturing process involves packaging the product in suitable containers, such as drums or bags, and storing it in a controlled environment to maintain its quality and stability. Proper labeling and documentation are essential for traceability and regulatory compliance.

In conclusion, the manufacturing process of cellulose ethers involves the extraction of cellulose from natural sources, alkali treatment, etherification, purification, and quality control. Each step is crucial in producing cellulose ethers with the desired properties for various applications. The process requires careful control of reaction conditions, choice of etherifying agents, and purification techniques to achieve consistent and high-quality cellulose ether products.

Why Choose Kima Chemical For Cellulose Ether?

Kima Chemical has been committed to the scientific research and development of cellulose ether and related products, and has overcome the key technical problems that restrict production.

In the process of cellulose ether research and development, KIMA company established a special technical research team to solve many industry problems from the perspectives of equipment.

Talent is the biggest core competitiveness of an enterprise. Relying on the people-oriented corporate culture and the platform advantages of listed companies.

With our own cellulose ether factory, KIMA can provide customized products and services for different customer needs, which are difficult for competitors to compete.

To continuously contribute value to the society, our corporate culture concept is Dedicated to making human beings healthier and the environment more friendly.

For more informationabout cellulose ether uses, please feel free to contact us!

There are many hydroxypropyl cellulose suppliers, but we are one of the best choices for you.

在线联系供应商

Other supplier products

| Oil Drilling Grade CMC | Oil drilling grade Carboxymethyl Cellulose (CMC) is water soluble polymer derived from cellulose that is commonly used as a thickening, stabilizing... | |

| Paint Grade CMC | Paint grade CMC (Sodium Carboxymethyl Cellulose) is a type of cellulose ether that is commonly used as a thickener, stabilizer, and dispersant in p... | |

| Food Grade CMC | Food Grade CMC refers to a type of food additive known as sodium carboxymethyl cellulose, which is derived from cellulose, a naturally occurring su... | |

| Paper-making Grade CMC | Paper-making grade CMC (Sodium Carboxymethyl Cellulose) is cellulose ether that is used in the paper-making industry as a retention and drainage ai... | |

| HPMC F4M | KimaCell®HPMC F4M Hydroxypropyl methylcellulose is used as a binder and disintegrant. Low-viscosity HPMC dissolves in water to form a clear to ... |

Same products

| Peptide Technology Cooperation & Transfer | 卖方: PeptiOrigin Biotechnology Co., Ltd. | Peptide Technology Cooperation & Transfer Driving Innovation Through Strategic Partnerships ... | |

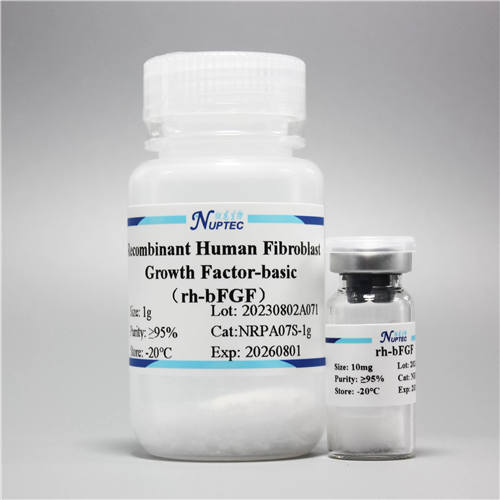

| Recombinant Human Fibroblast Growth Factor-basic | 卖方: Hangzhou NeuroPeptide Biological Science and Technology Incorporation, Ltd | Physical Appearance:Freeze-dried powder Formulation:5mMPB(pH7.4) before freeze-drying TheorypI:... | |

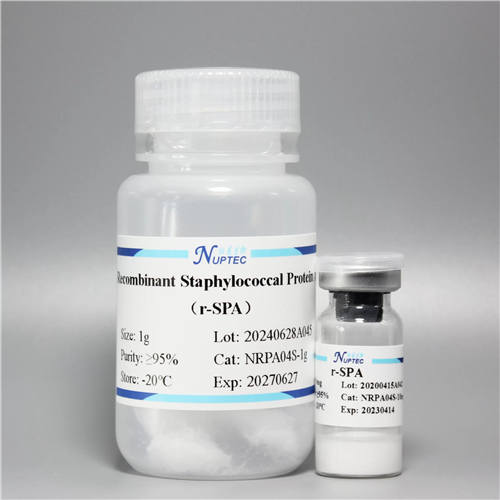

| Recombinant Staphylococcal Protein A | 卖方: Hangzhou NeuroPeptide Biological Science and Technology Incorporation, Ltd | TheorypI:5.10 Resources:Escherichia coli(E. coli) Purity:≥95% Storage condition:-20℃ Stora... | |

| NuPerley Core 700 | 卖方: Hangzhou NeuroPeptide Biological Science and Technology Incorporation, Ltd | NuPerley Core 700 Matrix:Rigid agarose microsphere Ligand:n-octylamine Particle size, d50:~90 ... | |

| Q NUPharose Fast Flow | 卖方: Hangzhou NeuroPeptide Biological Science and Technology Incorporation, Ltd | Matrix:6% Cross-linked agarose Ligand:Quaternary ammonium salt, -CH2CH(OH)CH2N(CH3)3+ Particle ... |