Paper-making Grade CMC

Paper-making grade CMC (Sodium Carboxymethyl Cellulose) is cellulose ether that is used in the paper-making industry as a retention and drainage aid, as well as a paper surface sizing agent.

It is a water-soluble cellulose derivatives made by reacting cellulose with sodium hydroxide and monochloroacetic acid.Paper-making grade CMC is used in the pulp and paper industry to improve the efficiency of the paper-making process and to enhance the properties of the paper, including strength, porosity, and surface smoothness. It is commonly used in the production of various types of paper, including newsprint, writing paper, and packaging materials.In the paper-making process, paper-making grade CMC is typically added to the pulp slurry before it is formed into sheets, and it is used in concentrations ranging from 0.01 to 1% by weight of the dry pulp. It can also be added as a surface sizing agent, applied to the surface of the paper after it has been formed.

How To Use CMCPaper?

Paper-making grade CMC (Carboxymethyl Cellulose) is typically used as an additive in the paper-making process to improve the retention and drainage of pulp fibers, as well as to enhance the properties of the paper. Here are some general guidelines on how to use paper-making grade CMC:

Determine the concentration: The recommended concentration of CMC in paper-making typically ranges from 0.01 to 1% by weight of the dry pulp, depending on the desired effect.

Add to the pulp: CMC should be added to the pulp slurry during the paper-making process, typically after the pulp has been beaten and refined. It is important to add CMC slowly and mix thoroughly to ensure that it is evenly dispersed.

Mix thoroughly: Once the CMC has been added, the pulp slurry should be mixed thoroughly to ensure that it is well dispersed and the CMC is fully dissolved.

Adjust pH: The pH of the pulp slurry may need to be adjusted to ensure that the CMC is fully activated and effective.

Test: It is important to test the paper to ensure that it has the desired properties, such as good strength, porosity, and surface smoothness.

There are many methyl cellulose manufacturersin China, but we are one of the best to meet all the needs of customers.

在线联系供应商

Other supplier products

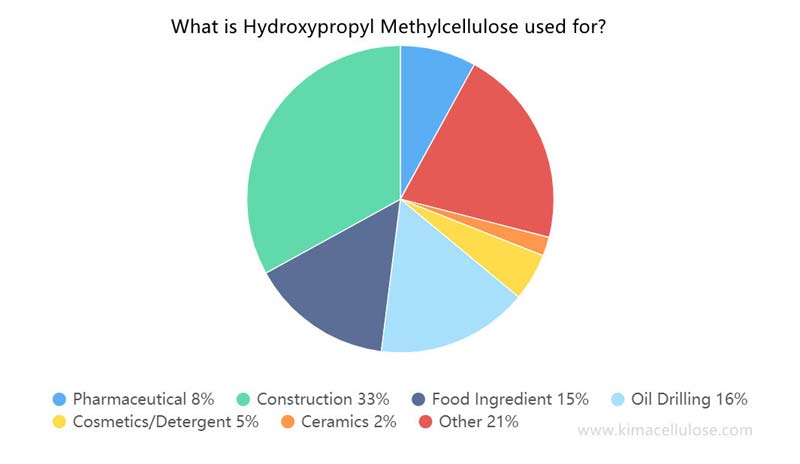

| Hydroxypropyl Methylcellulose (HPMC) Wholesale | HPMC Definition: Hydroxypropyl Methylcellulose (HPMC), also known as hypromellose, is a non-ionic cellulose ether made from natural polymer such as... | |

| Hydroxyethyl Methyl Cellulose (HEMC) Wholesale | CAS 9032 42 2 Hydroxyethyl methyl cellulose (HEMC) is a type of cellulose ether that is derived from natural cellulose. It is a non-ionic, water-s... | |

| Hydroxypropyl Methylcellulose (HPMC) Wholesale | Mydroxypropyl Méthylcellulose(HPMC), also known as , is a non-ionic cellulose ether made from natural polymer such as refined cotton or wood... | |

| Ethyl Cellulose (EC) Wholesale | CAS9004 57 3 Ethyl Cellulose (EC), known as the ethyl ether of cellulose, is a cellulose derivative in which ethoxy groups replace the hydroxyl ... | |

| Food Grade CMC | Food Grade CMC refers to a type of food additive known as sodium carboxymethyl cellulose, which is derived from cellulose, a naturally occurring su... |

Same products

| Peptide Technology Cooperation & Transfer | 卖方: PeptiOrigin Biotechnology Co., Ltd. | Peptide Technology Cooperation & Transfer Driving Innovation Through Strategic Partnerships ... | |

| Recombinant Human Fibroblast Growth Factor-basic | 卖方: Hangzhou NeuroPeptide Biological Science and Technology Incorporation, Ltd | Physical Appearance:Freeze-dried powder Formulation:5mMPB(pH7.4) before freeze-drying TheorypI:... | |

| Recombinant Staphylococcal Protein A | 卖方: Hangzhou NeuroPeptide Biological Science and Technology Incorporation, Ltd | TheorypI:5.10 Resources:Escherichia coli(E. coli) Purity:≥95% Storage condition:-20℃ Stora... | |

| NuPerley Core 700 | 卖方: Hangzhou NeuroPeptide Biological Science and Technology Incorporation, Ltd | NuPerley Core 700 Matrix:Rigid agarose microsphere Ligand:n-octylamine Particle size, d50:~90 ... | |

| Q NUPharose Fast Flow | 卖方: Hangzhou NeuroPeptide Biological Science and Technology Incorporation, Ltd | Matrix:6% Cross-linked agarose Ligand:Quaternary ammonium salt, -CH2CH(OH)CH2N(CH3)3+ Particle ... |