Positioning Components

Keep the following points in mind when positioning components.

One or more components can be added for positioning even when the positioning tool is active. The added component will immediately get the transformations shared by the other components.

If 2 or more components are selected for positioning, you cannot deselect any of them until they have been positioned.

Use the dragger's handles to move and components of positioningas a single unit. While dragging the linear handle, fix the components to a geometric reference and constrain them.

If you add one or more components to a group of multiple components already positioned, any constraints previously applied when positioning the components are clear.

Positioning Type Description

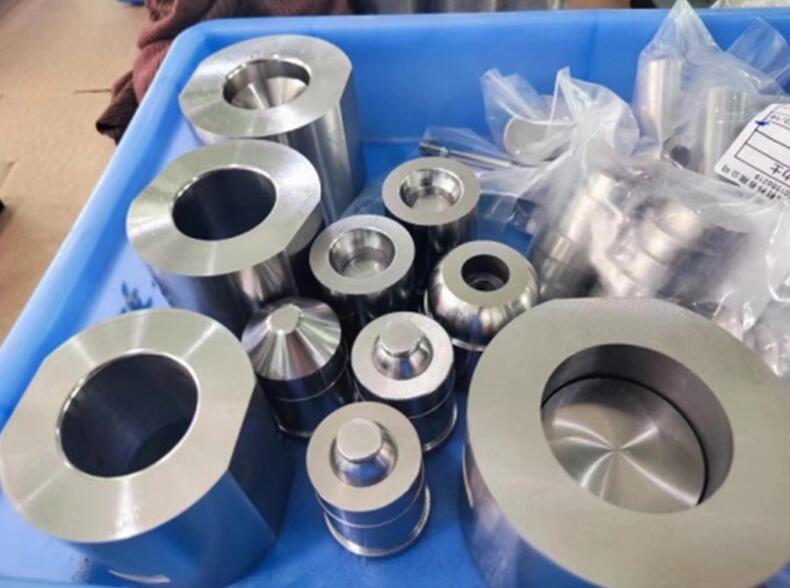

[1] Method of using a positioning pin The workpiece is positioned using a cylindrical or tapered positioning pin.

[2] Method of adjusting the positioning surface (point) Allows the use of adjustable positioning pins to adjust the orientation.

[3] Method of adjusting the position of the workpiece to a fixed datum plane Press the face of the workpiece onto the datum plane for positioning.

[4] Centering Positioning a cylindrical workpiece to its center.

[5] Indexing Positioning the workpiece at a specified distance in a straight line.

[6] Method using V-slot Position the cylindrical workpiece along the V-slot in the longitudinal direction.

The Principles of Positioning

What is positioning refers to the highly accurate maintenance of the positional relationship between two objects. any one object. As a basis for positioning... (e.g., positioning fixture) Another object. The object to be positioned to the positioning base... (e.g.: workpiece) To place two objects in a configuration where their positional relationship is set in an efficient manner (refer to [Figure 1]).

Select the positioning method according to the operation to be performed (manual, automatic, prototyping, mass production, etc.) and the characteristics of the workpiece (accuracy level, appearance quality level, material, etc.).

As a professional precision machining suppliers, Hui Huan has high-quality precision machining china. Welcome to contact us if needed.

在线联系供应商

Other supplier products

| Carbide Mold Components | Carbide Components We are very capable of customizing punches and dies to produce precision tungsten punches, bushings, ejectors, and die componen... | |

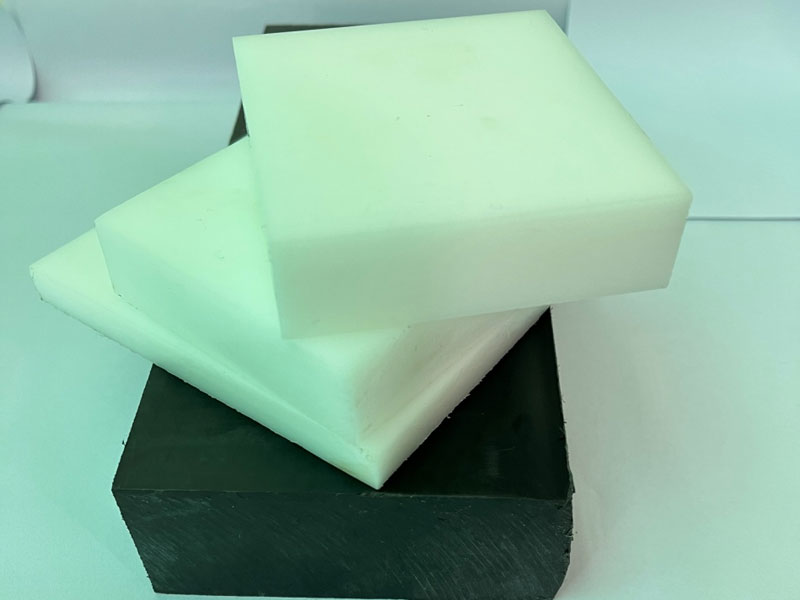

| CNC Machining Material | Metal Material Machining Aluminum Alloys Aluminum alloy material is divided into: 6061 mainly contains magnesium and silicon elements, suitable... | |

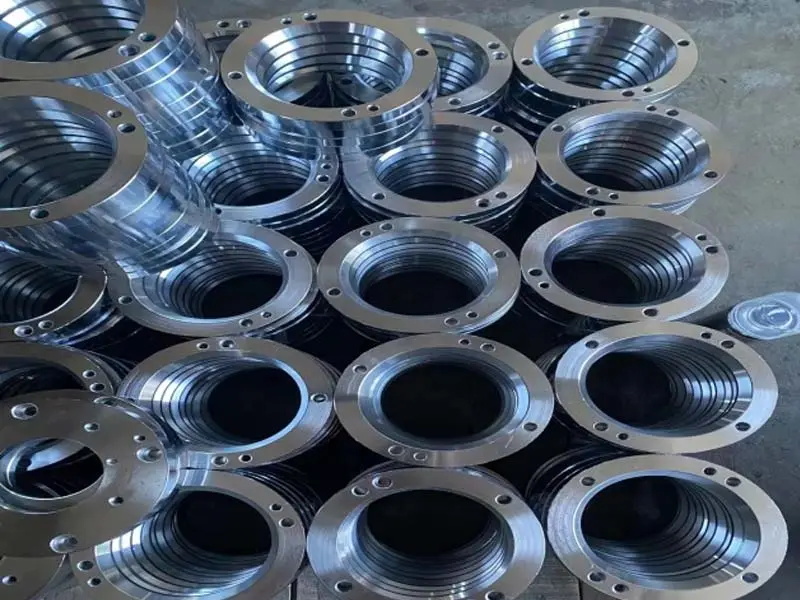

| Metal CNC Machining Parts | cnc metal parts factory/ cnc machining metal parts factory custom cnc metal parts/ cnc machined metal parts/ metal cnc machined parts/ metal cnc p... | |

| Custom Precision Machined Parts | As the leading supplier of custom precision parts, we have 10 years of experience in custom fabrication services which include CNC machining servic... | |

| Electroplating | ElectroplatingServices The custom electroplatingprocess is a method of laying a layer of metal on a conductive body using the principle of electro... |

Same products

| Tool Scoot – Heavy-Duty CNC Tool Holder Storage by Uratech | 卖方: Uratech USA Inc | Tool Scoot– Heavy-Duty CNC Tool Holder Storage by Uratech When precision, mobility, and du... | |

| Car Signs Molds | 卖方: Zhuozhou Yihua Mould Factory | Our company has long provided automobile manufacturers with automobile sign moldsand products. Au... | |

| DG-I Gantry Crane Rail Changer | 卖方: 武汉联科瑞际轨道设备有限公司 | ||

| 便携式轨道垂直捣固机 | 卖方: 武汉联科瑞际轨道设备有限公司 | ||

| NSiC stalk tube,NBSiC stalk ceramic, advanced NSiC riser tube, nitride bonded silicon riser tube, LPDC machine parts | 卖方: 唐山星斗碳化硅陶瓷有限公司 | 星斗公司的升液管作为低压铸造机上的关键部件,具有较好的耐热冲击性、耐腐蚀性、较传统材料寿命更长,性价比更高,可以很好的满足低压铸造行业要求。 |