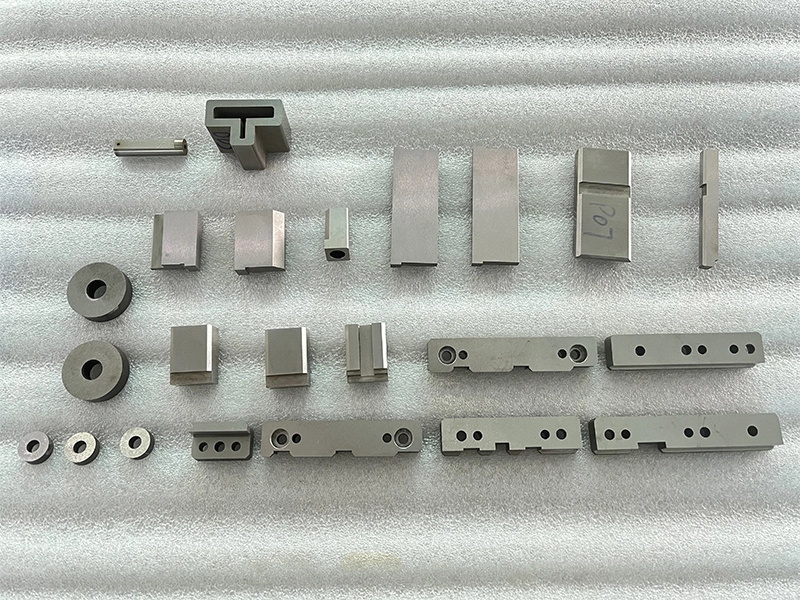

Aluminum Precision Spare Parts

Aluminum Precision Spare Parts

When it comes to aluminum precision parts production, aluminum die-casting surface treatment is indispensable which should be divided into pre-treatment and post-treatment, pre-treatment is to remove surface oxidation, and oil increases the adhesion of post-treatment and improves the appearance of the effect. For aluminum precision machining parts, what aluminum die-casting surface pretreatment most commonly used are shot blasting, sandblasting, and phosphating 3, post-treatment is generally used spraying, oxidation, electroplating, and electrophoresis 4. Other surface treatment methods due to cost reasons are only applied to products with special requirements.

What Are The Process Characteristics of Aluminum Parts CNC Machining?

About Aluminum CNC Precision Parts

After aluminum parts CNC machining, because aluminum is a metal that is easy to self-oxidize, as a professional CNC aluminum parts supplier, we apply surface treatment to aluminum parts for the protection of the parts or for other assembly requirements. Surface treatment of precision aluminum parts processing:

Sandblasting can be used by a blasting machine to pressurize shot diamonds, and hit the metal surface, according to the size of the diamond (unit with mesh) to form the metal surface of the matte grinding effect.

Aluminum CNC precision parts refer to metal parts that are machined from aluminum materials using Computer Numerical Control (CNC) machines. These CNC machine aluminum parts are characterized by their high precision, tight tolerances, and intricate shapes. These parts are widely used in a variety of industries such as automotive, aerospace, and medical. Because of their strength and lightweight characteristics, aluminum is an ideal material for making OEM CNC milling parts.

As one of cnc aluminum parts suppliers, we will do our best to meet all the needs of customers.

We are a professional precision machining companyfocusing on OEM & ODM customized services of precision quality machining. We own a precision machining factory specializing in precision machining china, non-standard spare part processing, metal stamping and metal prototyping.

在线联系供应商

Other supplier products

| Copper Precision Spare Parts | Copper Precision Spare Parts T1, T2 copper is mainly used as conductive, heat-conducting and corrosion-resistant components, such as wires, cables,... | |

| POM Non-standard Parts | Polyacetal ( POM ) properties for crystalline thermoplastic, with an apparent melting point of 165 ~ 175 ℃, the nature of the closest to the metal,... | |

| Metal CNC Machining Parts | Metal CNC Machining Parts Custom cnc metal parts are suitable for hand board production and small batch production, various types of parts in large... | |

| Copper Precision Spare Parts | T1, T2 copper is mainly used as conductive, heat-conducting and corrosion-resistant components, such as wires, cables, conductive screws, shells an... | |

| Metal Stamping Parts | Metal Stamping Components Most of the world's steel is made into finished products by stamping. The body, chassis, fuel tank and radiator sheet of... |

Same products

| Tool Scoot – Heavy-Duty CNC Tool Holder Storage by Uratech | 卖方: Uratech USA Inc | Tool Scoot– Heavy-Duty CNC Tool Holder Storage by Uratech When precision, mobility, and du... | |

| Car Signs Molds | 卖方: Zhuozhou Yihua Mould Factory | Our company has long provided automobile manufacturers with automobile sign moldsand products. Au... | |

| DG-I Gantry Crane Rail Changer | 卖方: 武汉联科瑞际轨道设备有限公司 | ||

| 便携式轨道垂直捣固机 | 卖方: 武汉联科瑞际轨道设备有限公司 | ||

| NSiC stalk tube,NBSiC stalk ceramic, advanced NSiC riser tube, nitride bonded silicon riser tube, LPDC machine parts | 卖方: 唐山星斗碳化硅陶瓷有限公司 | 星斗公司的升液管作为低压铸造机上的关键部件,具有较好的耐热冲击性、耐腐蚀性、较传统材料寿命更长,性价比更高,可以很好的满足低压铸造行业要求。 |