CNC Milling

CNC Milling

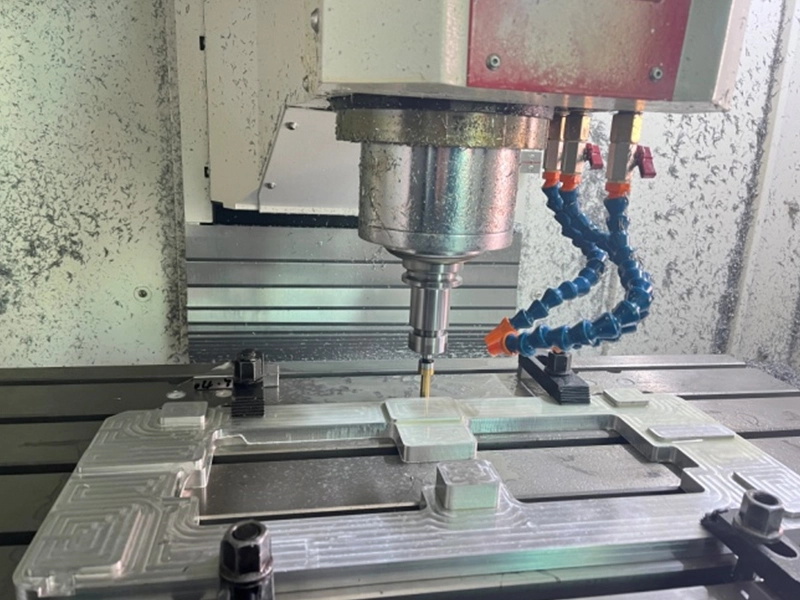

CNC Milling is the ideal method for rapid prototyping and for batch manufacturing of plastics and metals. As a cnc milling service supplier, we provide you with fast CNC machining services and manufacturing services. It is the process of using a revolving tool to remove material by pushing the tool into the workpiece. This may be accomplished by changes in direction, cutter speed and pressure on one or several axes. Milling covers a wide variety of operations and machines, ranging from small individual parts to large, heavily grouped milling operations. It is one of the most common processes for machining custom parts to exact tolerances. Milling can be performed using a wide variety of machines.

What is CNC Milling?

CNC milling is a machining process that uses a cutting tool mounted on a rotating spindle to selectively remove material from the original substrate. The workpiece is firmly mounted on the table and the table moves or rotates in different planes, so the tool can work at multiple angles. Complex CNC milling machines can have five or more independent axes of motion to create more complex shapes or to avoid moving the workpiece to one machine. The milling process can be divided into vertical and horizontal milling, circumferential and end milling and down and reverse milling depending on the milling machine, the milling tool and the form of motion.

CNC Milling Capability

CNC milling is a machining process that uses Computer Numerical Control (CNC) to create precision parts and components with tight tolerances. This process involves the use of a milling machine equipped with cutting tools to remove material from a workpiece. CNC milling is capable of producing complex shapes, intricate details, and smooth finishes, making it ideal for a wide range of applications, including automotive, aerospace, and medical components.

|

Max dimensions |

1600mm x 1200 mm x 900 mm |

|

Tolerance |

Linear dimension: +/-0.025 mm |

|

Hole diameters (not reamed): +/- 0.025 mm |

|

|

Shaft diameters: +/- 0.025 mm |

|

|

The smallest feature size we make is 0.5 mm, it depends on the product geometry and the material used. |

|

|

Burrs and chamfers |

Default deburring and chamfering as per drawing processing requirements |

|

Surface Finish |

The standard surface finish is 32 Ra or better. |

As one of cnc milling service suppliers, we can provide professional services for clients, and the cnc milling service priceis reasonable, anything you need, please contact us.

We are a professional precision machining companyfocusing on OEM & ODM customized services of china precision machining. We own a precision machining factory specializing in precision cnc machining, non-standard spare part processing, metal stamping and metal prototyping.

在线联系供应商

Other supplier products

| Punches and Bushings Parts | Punches and Bushings Parts When punching holes with a concave die, the standard of hole diameter is based on the diameter of the convex die. For ex... | |

| Rapid Prototyping Parts | Using 3D CAD data, precision parts prototypingis a form of manufacturing technology used to quickly construct a scale model of a real item or assem... | |

| CNC Milling | CNC Milling CNC Milling is the ideal method for rapid prototyping and for batch manufacturing of plastics and metals. As a cnc milling service sup... | |

| PEEK Non-standard Parts | PEEKprecision machiningmaterial is a new type of semi-crystalline aromatic plastic engineering plastics, with extremely good physical and mechanica... | |

| EDM Spark | Electrical Discharge Machining ServicesSpark During the EDM process, an electric current crosses the gap between the electrode and the workpiece (... |

Same products

| Tool Scoot – Heavy-Duty CNC Tool Holder Storage by Uratech | 卖方: Uratech USA Inc | Tool Scoot– Heavy-Duty CNC Tool Holder Storage by Uratech When precision, mobility, and du... | |

| Car Signs Molds | 卖方: Zhuozhou Yihua Mould Factory | Our company has long provided automobile manufacturers with automobile sign moldsand products. Au... | |

| DG-I Gantry Crane Rail Changer | 卖方: 武汉联科瑞际轨道设备有限公司 | ||

| 便携式轨道垂直捣固机 | 卖方: 武汉联科瑞际轨道设备有限公司 | ||

| NSiC stalk tube,NBSiC stalk ceramic, advanced NSiC riser tube, nitride bonded silicon riser tube, LPDC machine parts | 卖方: 唐山星斗碳化硅陶瓷有限公司 | 星斗公司的升液管作为低压铸造机上的关键部件,具有较好的耐热冲击性、耐腐蚀性、较传统材料寿命更长,性价比更高,可以很好的满足低压铸造行业要求。 |