CNC Turning

CNC Turning

OEM CNC turning is the perfect way to make deep holes, machine threads, and all types of cylinder shapes with excellent surface finishes. The cnc turning machining serviceis that the cutting tool continues to cut until the desired programmed shape is achieved as the workpiece rotates in the machine. It is important to note that a CNC lathe turning center has different tools in the turret, all of which are controlled by computer programs and codes. Yet, custom CNC turning machines that can accommodate more tools are more complex and have more features, making them more suitable for complex designs.

What is CNC Turning Machining Service?

Turning in CNC is a manufacturing process in which a bar of material is clamped in a chuck and rotated while a tool is fed into the workpiece to remove the material and form the desired shape. This is also known as "subtractive machining" because it involves the removal of material. The cnc turning machining factorieswould use this technique allowing for a variety of shapes, sizes, features, and even material types. The cutting energy for CNC turning operations is provided primarily by the workpiece rather than the tool. The CNC turning process is the most basic and common method of cutting, and it occupies a very important place in production. Turning is suitable for processing rotary surfaces, and most of the workpieces with rotary surfaces can be processed by CNC precision turning methods, such as internal and external cylindrical surfaces, internal and external conical surfaces, end faces, grooves, threads, and rotary forming surfaces, etc. The tools used are mainly turning tools.

CNC Turning Capability

Hhuitech, a professional cnc turning machining supplier, provides different general tolerance options and you can also specify the available tolerances in accordance with ISO 2768-mK.

|

Max dimensions of the CNC lathe machine turning |

1600mm x 1200 mm x 900 mm |

|

Tolerance |

Linear dimension: +/-0.025 mm |

|

Hole diameters (not reamed): +/- 0.025 mm |

|

|

Shaft diameters: +/- 0.025 mm |

|

|

The smallest feature size we make is 0.5 mm, it depends on the product geometry of OEM CNC turning machining products and the material used. |

|

|

Burrs and chamfers |

Default deburring and chamfering as per drawing processing requirements |

|

Surface Finish |

The standard surface finish is 32 Ra or better. |

We are one ofprofessional precision manufacturing companiesfocusing on OEM & ODM customized services of precision quality machining. We own a precision machining chinafactory specializing in precision cnc machining, non-standard spare part processing, metal stamping and metal prototyping.

在线联系供应商

Other supplier products

| CNC Machining Parts | CNC Machining Parts OEMparts cnc machiningare components produced by CNC (computer numerical control) machining. CNC machining is a manufacturing ... | |

| Punches and Bushings Parts | Punches and Bushings Parts When punching holes with a concave die, the standard of hole diameter is based on the diameter of the convex die. For ex... | |

| EDM Spark | Electrical Discharge Machining ServicesSpark During the EDM process, an electric current crosses the gap between the electrode and the workpiece (... | |

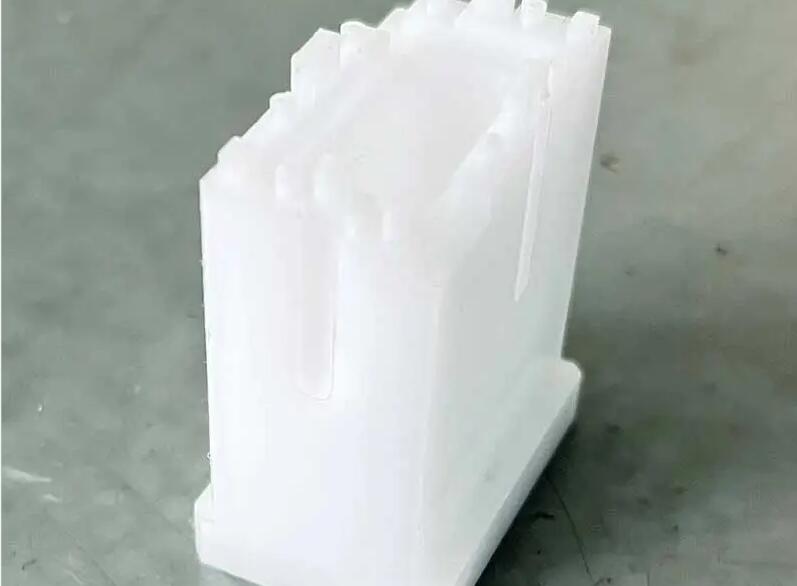

| PEEK Non-standard Parts | PEEK Non-standard Parts PEEK material is a new type of semi-crystalline aromatic plastic engineering plastics, with extremely good physical and mec... | |

| Rubber Prototyping Parts | Liquid silicone rubber (LSR) molding is a form of injection molding. The liquid silicone rubber is first injected into the mold, then the liquid is... |

Same products

| Tool Scoot – Heavy-Duty CNC Tool Holder Storage by Uratech | 卖方: Uratech USA Inc | Tool Scoot– Heavy-Duty CNC Tool Holder Storage by Uratech When precision, mobility, and du... | |

| Car Signs Molds | 卖方: Zhuozhou Yihua Mould Factory | Our company has long provided automobile manufacturers with automobile sign moldsand products. Au... | |

| DG-I Gantry Crane Rail Changer | 卖方: 武汉联科瑞际轨道设备有限公司 | ||

| 便携式轨道垂直捣固机 | 卖方: 武汉联科瑞际轨道设备有限公司 | ||

| NSiC stalk tube,NBSiC stalk ceramic, advanced NSiC riser tube, nitride bonded silicon riser tube, LPDC machine parts | 卖方: 唐山星斗碳化硅陶瓷有限公司 | 星斗公司的升液管作为低压铸造机上的关键部件,具有较好的耐热冲击性、耐腐蚀性、较传统材料寿命更长,性价比更高,可以很好的满足低压铸造行业要求。 |