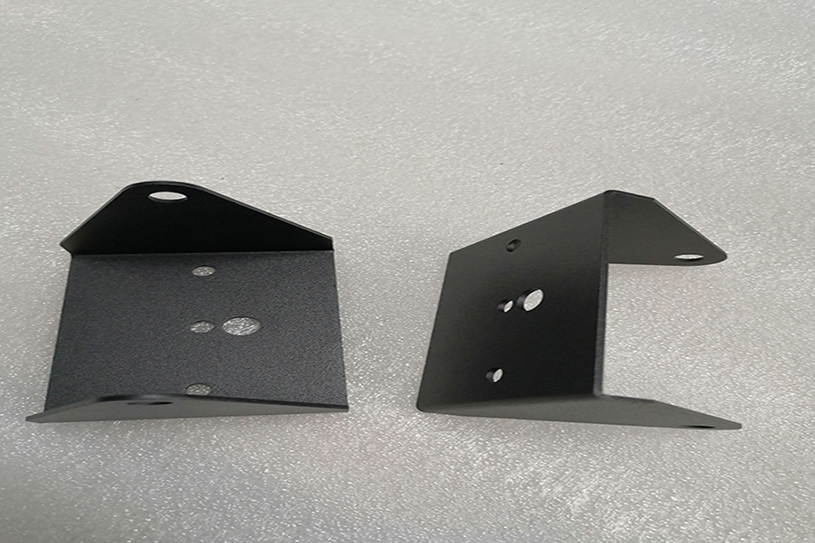

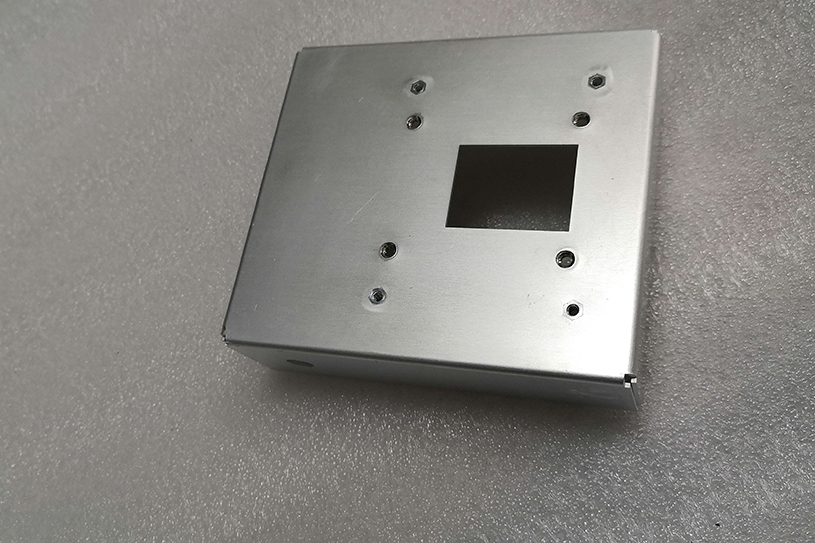

Custom Bending Electronic Enclosure

Custom metal enclosures electronics

Material:

SPCC, SGCC, SECC,Stainless Steel,copper, aluminum,and so on

Surface treatment:

Power coating, Polishing, Plating, Brushing, sandblasting, anodizing,passivation,silk-print ect.

Process:

Laser cutting, NCT Punching, CNC bending, riveting, welding, surface treatment and assembly and so on.

Key Specifications for Custom Electronic Enclosure

Tolerance: 0.1mm

Size: We can negotiate

Sea transport packaging options:besides common packing including plastic film & kraft paper packing, plastic bag packing , plywood board packing, wood box packing, pallet packing, bundle packing, we also offer customized packing based on client requirement.

Customization Process for Sheet Metal Electronics Enclosure

HSJ is a leading manufacturer of custom sheet metal electronics enclosures in China, offering a range of services from designing, material selection, process choosing, surface treatment, quality control, packing, online face-to-face confirmation, project meetings, and one-stop after-service. Our business includes power enclosures, energy enclosures, controller enclosures, solar enclosures, electric enclosures, medical enclosures, aircraft enclosures, industrial enclosures, and more.

Sheet metal electronics enclosure fabrication typically involves seven steps, which include designing, material selection, cutting, bending, welding, finishing, and assembly.

Designing

Design is the initial stage of sheet metal electronics enclosure fabrication, which includes developing a comprehensive design that satisfies the project's specifications and requirements. Typically, it takes 3-7 days to create a sample after the design has been approved.

Material Selection

After finalizing the design, the next step is to choose the appropriate sheet metal material, which is typically based on factors such as strength, durability, and cost. The materials that we usually choose and use are:

Aluminum (2A21/3003/5052/5083/6061/6082/8011)

Carbon Steels (Q235, SPHC, SPCC, SPCD, SPCE, ST, ST12, ST13, ST14, ST15, ST14-T)

Stainless Steel (304, 304L, 312, 316, 317, 321, 347, 904L, 440, 17-4ph, 430, etc.)

Copper (C1020, C1100, C2100, 2200, 2300, 2400)

Brass (H62, H65, H68, H70, H80, H90, C2600, C2680, C2700, C5210, C5191, C51000, QBe2.0, C1100, T2)

|

Sheet Metal Electronics Enclosure |

|

|

Material |

Options |

|

Aluminum |

2A21,3003,5052,5083,6061,6082 ,8011 |

|

Carbon Steels |

Q235,SPHC,SPCC,SPCD,SPCE,ST,ST12,ST13,ST14,ST15,ST14-T |

|

Stainless Steel |

304,304L ,312 ,316,317,321,347,904L,440,17-4ph,430 etc |

|

Copper |

C1020,C1100,C2100,2200,2300,2400 |

|

Brass |

H62,H65,H68,H70,H80,H90,C2600,C2680,C2700,C5210,C5191,C51000,QBe2.0,C1100,T2 |

Sheet Metal Cutting

Sheet metal cutting is a crucial step in the fabrication process, where the sheet metal is cut to the required size and shape using a variety of cutting tools. Laser cutting machines and shears are commonly used to achieve precise cuts. At HSJ, we offer sheet metal cutting services for sizes ranging from 0.010.01mm to 20004000mm, with a thickness of less than 6mm. Additionally, we can accommodate special sizes and thicknesses based on customized requirements.

Sheet Metal Bending

After the sheet metal cutting process, the next step is sheet metal bending, which involves using a press brake to bend the metal into the desired shape. The press brake applies pressure to the metal using a punch and a die, which creates the bend. At HSJ, we can accommodate sheet metal sizes up to 3000mm * 6000mm and can also accept customized sizes. Our metal parts meet the CE and RoHS standards and are held to tight tolerances of +/- 0.005" (+/- 0.127 mm). For flat parts, the tolerance is +/- 0.010mm, while for bent parts, the tolerance is +/- 0.030mm.

Sheet Metal Welding

After shaping the sheet metal to the desired configuration, the cabinet structure is formed through sheet metal welding using different techniques such as TIG welding and MIG welding.

Finishing

Once the welding process is complete, the cabinet undergoes sanding, cleaning, and finishing to achieve a sleek, polished appearance. Additionally, we can perform various customized finishes such as sandblasting, shot blasting, grinding, tumbling, polishing, brushing, spraying, painting, oiling, blackening, anodizing, electrochemical polishing, electroplating, depending on the customer's request.

Assembly

Assembly is the ultimate stage in the fabrication process of the Electronics Enclosure made from sheet metal. It comprises fastening hardware and accessories like hinges, handles, and locks to the cabinet. After completion, a quality inspection is conducted, and the finished cabinet is shipped to the customer. We have successfully assembled cabinets for numerous clients, including those in the help, controller, and aircraft industries.

If you are seeking a high-quality sheet metal Electronics Enclosure, HSJ is undoubtedly the right choice for you. We offer a complete range of services, including design, processing, finishing, quality control, and customer service, all aimed at ensuring your satisfaction. We are committed to meeting your requirements and achieving your goals.

Application of Custom Sheet Metal Enclosure

Custom sheet metal electronic enclosures, can be used for a wide range of applications across various industries. Here are some examples:

Electronics: Sheet metal electronics enclosure can be used to house electronic equipment such as servers, routers, and switches. They provide protection from environmental factors such as dust, moisture, and electromagnetic interference.

Telecommunications: Telecommunications companies use custom electronic enclosures to house equipment such as power supplies, battery backup systems, and communication equipment. These enclosures protect the equipment from weather and vandalism.

Medical: Medical equipment such as diagnostic machines and laboratory equipment can be housed in sheet metal electronic enclosures for protection from external elements.

Industrial: Sheet metal enclosures can be used to protect industrial equipment from harsh environments such as dust, heat, and chemicals. They can also be used to house control panels and electrical equipment.

Military and Aerospace: Custom sheet metal electronic enclosures are commonly used in military and aerospace applications to protect sensitive equipment from harsh environments and electromagnetic interference.

In summary, custom sheet metal enclosures can be used in a wide range of industries and applications to provide protection for valuable equipment and devices.

HSJ is a professional China sheet metal fabrication services supplier. With years of experience, we specialize in making custom sheet metal electronic enclosures for different applications of various industries according to our customer's unique needs. We have custom electronic enclosures, custom aluminum enclosures electronics, and custom PCB enclosures for you, which are widely used in LED lighting, electronics telecommunication, home appliances, furniture, auto Industries, etc.

If you are looking for a reliable supplier of custom electronic cases, don't hesitate to contact us!

As a professional china sheet metal manufacturer,we provide custom metal fabrication services,aluminum enclosure custom, secc sgccand etc. Want to know more? Please contact us.

There are many aerospace sheet metal manufacturers, but we are one of the best choices for you.

在线联系供应商

Other supplier products

| Precision Metal Stamping | Precision Metal Stamping Material: sus/aluminum/iron Surface treatment: powder coating Process: stamping Precision metal stamping mak... | |

| SECC Stamping & Forming Shell | SECC Stamping & Forming Shell Material: SECC (Electrolytic plate) 2.0mm Surface treatment: powder plating + silk-screen printing (we also... | |

| Machined Enclosures | Machined Enclosure Material: Carbon Steel/Stainless Steel/aluminum Surface treatment: Paint, powder coat, polish, silk-screen printing, a... | |

| Custom Aluminum Parts | Custom Parts Fabrication Material : aluminum (AS PICTURES) Process : CNC machine + deburrs Type : Broaching, Drilling, Etching / Chemical... | |

| Stamping Computer Enclosures | Surface treatment: in the photo we not show the surface treatment but we could offer the powder coating and anodizing and silk print and color pla... |

Same products

| Metal Insulated Composite Panel Systems | 卖方: Zhejiang Leboom Energy Conservation Technology Co., Ltd | Metal Insulated Composite Panel Systems The system is composed of fire-resistant composite metal... | |

| AluzincMg-Al-Zn Alloy Composite Panel Systems | 卖方: Zhejiang Leboom Energy Conservation Technology Co., Ltd | AluzincMg-Al-Zn Alloy Composite Panel Systems Introducing magnesium aluminum zinc composite pane... | |

| Aluminium Insulated Composite Panel Systems | 卖方: Zhejiang Leboom Energy Conservation Technology Co., Ltd | Aluminium Insulated Composite Panel Systems This system features composite panels manufactured i... | |

| 3D Aluminium Composite Panel Systems | 卖方: Zhejiang Leboom Energy Conservation Technology Co., Ltd | 3D Aluminium Composite Panel Systems The 3D Aluminium Composite Panelutilizes aluminum alloy she... | |

| Calcium Silicate Board Integrated Exterior Wall Insulation | 卖方: Zhejiang Leboom Energy Conservation Technology Co., Ltd | Calcium Silicate Board Integrated Exterior Wall Insulation and Decoration Panel Leboomoffers hig... |