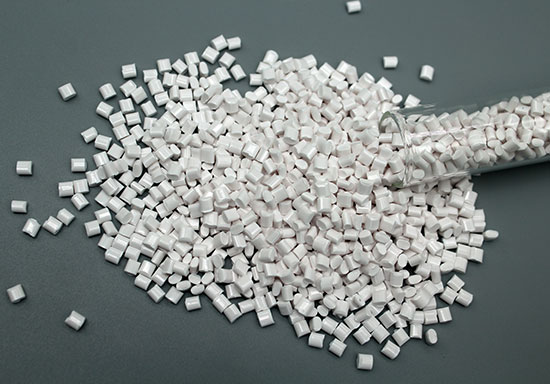

PA6 GF15 With High Tensile Strength (A1307C, A1317C) for Engineering Plastics

PA6 15GFwith high tensile strength is made by 15% glass fiber reinforced, toughened, polyamide 6 resin for injection molding.

Typical Application of PA6 GF15 with high tensile strength (A1307C)

PA6 with 15% glass fiber toughened plastics, due to its excellent properties, good appearance and easy processing characteristics, which has been successfully applied to the electrical field such as switches, controllers, the auto field such as heat dissipation barriers, accumulator shells, coolant pots, and the mechanical filed such as electric drill and motor housing, pump impeller, pulley, tool handle and bearing.

Other Details of PA6 GF15 with high tensile strength (A1307C)

Physical Property

|

Ash |

(15.0% 1 ISO3451/1) |

|

Conditioned |

600°C*2h |

|

Density |

(1180Kg/m3 1 ISO1183) |

|

Conditioned |

23°C |

|

Shrinkage Parallel Flow |

(0.5-0.7 % 1 ISO294-4) |

|

Shrinkage Vertical Flow |

(0.7-1.1% I ISO294-4) |

Mechanical Properties

|

Tensile strength(115.0MPa 1 ISO527) Conditioned |

5mm/ min |

|

Tensile Strain at Break(2.0% I ISO527) Conditioned |

|

|

Notched Impact Strength(125 0MPa I ISO527) Conditioned |

2mm/min |

|

Flexural Strength(175MPa 1ISO178) Conditioned |

2mm/min |

|

Flexural Modulus(5250 MPa I ISO178) Conditioned |

5mm/ min |

Thermal Property

|

Melting Point |

(220°C I ISO11357) |

|

Hot Deformation Temperature |

(175*C I ISO75) |

|

Conditioned |

|

|

Flammability Class |

(HB 1UL94) |

|

Conditioned |

mm |

Injection Molding Conditions

|

Drying Temperature |

130°C |

|

Drying Time |

3h |

|

Cylinder Temperature |

240-260°C |

|

Nozzle Temperature |

240-260*C |

|

Tooling Temperature |

80*C |

* Molding conditions arejustfor reference, please make an adjustment based on the actual situation!

Suzhou ANMEIMaterial Technology Co., Ltd. – the professional supplier of engineering plastic and the color masterbatchwas founded in 2013, which is located in Tongli - the millennium ancient town, 50km far away from Shanghai, the location is very convenient for transportation.

As a modified plastics inc, we will do our best to meet all the needs of customers.

在线联系供应商

Other supplier products

| Anmei-ABS Engineering Plastic | ABS resin is a terpolymer composed of acrylonitrile, butadiene and styrene. ABS has the rigidity, chemical resistance and heat resistance of polyac... | |

| ABS Engineering Plastic in Anmei | ABS resin is a terpolymer composed of acrylonitrile, butadiene and styrene. ABS has the rigidity, chemical resistance and heat resistance of polyac... | |

| Color Masterbatch for Engineering Plastics | Color Masterbatch for Engineering Plastics As an engineering plastic company, Anmei serves customers with tailored-making solutions from standard ... | |

| PA66 GF30 Halogenated FR (A2014F, A2114F) for Engineering Plastics | PA66GF30FR is a Nylon 66 with 30% glass-fibers and flame retardant halogenated. Typical Application of PA66 GF30 Halogenated FR (A2014F) The ad... | |

| Anmei-PA66 GF for Engineering Plastics | Anmeifocuses on the production of modified engineering plastics. We have polyamide PA66 modified products with propertiesof heat-resistant, rein... |

Same products

| Two-Shot Injection Molds | 卖方: WIT MOLD LIMITED | Two-Shot Injection Molds Advantages of two-shot injection molding The benefits of Double Inject... | |

| precision injection molding | 卖方: WIT MOLD LIMITED | precision injection molding Precision injection moldingis a method demanding unparalleled accura... | |

| Custom Plastic Molds molding | 卖方: WIT MOLD LIMITED | Custom Plastic Molds molding Plastic Molds molding servicesprovide many extremely versatile part... | |

| Negative Pressure Physiotherapy Tank Molds | 卖方: Zhuozhou Yihua Mould Factory | The negative pressure tank is a disposable consumable for male negative pressure treatment. This ... | |

| PLC Casing Molds | 卖方: Zhuozhou Yihua Mould Factory | The PLC housingbelongs to a kind of rail electrical module. It not only needs to achieve the fit ... |