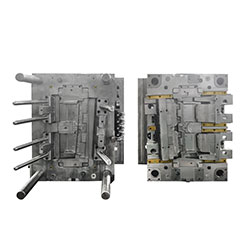

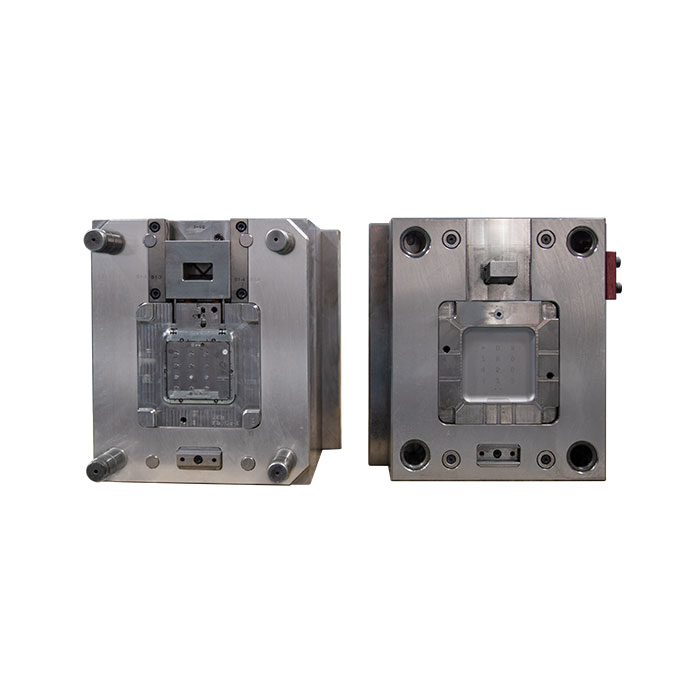

Automotive Mold

Large drop of automotive moldtop and bottom; The mold manufacturing technology is complicated; The injection system is many and complicated; The mold cost is ver high.

AUTOMOTIVE MOLD TYPES

Automotive AC Air Outlet

The air outlets of automotive AC are generally assembled by multiple parts, classified according to their functions and purposes: there are exterior molds, functional molds, or both exterior and functional molds.

Automotive Mold Manufacturers

With over 15 years of experience in automotive mold development and production, USM will make mold flow analysis from the DFM report step to ensure that the pressure will be controlled at a reasonable range during injection, and there are no weld marks and other defects on the part surface.

Automotive Grille Mold

The part surface of the air intake grille generally has several treatment methods such as leather texture, sandblasting, paint spraying, and electroplating, the materials usually are PP, ABS, ASA, etc., and the surface of the bumper decorative grille is generally treated with leather texture and sandblasting, mainly PP material.

Automotive Door Mold

The plastic application in automotive is divided into interior parts, exterior parts, and functional parts. According to different material properties, plastics are usually divided into three types: general plastics, engineering plastics, and special plastics.

Auto Parts Mould

The automotive console is an external part in automotive interior parts, and no weld line on the part surface, the console's gating system generally uses a valve gate of hot runner system, the gate position usually has a direct injection gate on the non-critical surface which is to save plastic material, the shut-off area will be injected on side of the non-critical surface, or the middle area will be injected to the non-critical surface by the banana gate.

Automotive Molds Characteristics

If you want to know more about automotive mold technology, please visit our website.

As one of custom plastic mold manufacturers, we serve different industries, especially in the fields of water-assisted injection mold,gas injection mold, two-color mold (2k molds),multi cavity moldand pre-deformed mold with professional experience make us stand out in this industry.

在线联系供应商

Other supplier products

| Engine Coolant Pipe | Engine Coolant Pipe Gas-assisted injection moldequipment mainly includes nitrogen generators, superchargers, gas-assisted controllers, nitrogen ... | |

| Gas & Water Assisted Injection Mold | Gas Assist Injection Molding Design Guide Since the thermal conductivity and heat capacity of water are much bigger than nitrogen, so the inject... | |

| Medical Plastic Injection Mold | Medical Plastic Injection Mold For medical device injection molding companies, it means that medical supervisors are required to supervise and man... | |

| Medical Plastic Injection Mold | For medical device injection molding companies, it means that medical supervisors are required to supervise and manage the materials used to manufa... | |

| 2K Mold | 2KMolds The rotary mold is composed of two-cavity and core sides, the two core sides are the same, only the cavity sides is different which the ... |

Same products

| Two-Shot Injection Molds | 卖方: WIT MOLD LIMITED | Two-Shot Injection Molds Advantages of two-shot injection molding The benefits of Double Inject... | |

| precision injection molding | 卖方: WIT MOLD LIMITED | precision injection molding Precision injection moldingis a method demanding unparalleled accura... | |

| Custom Plastic Molds molding | 卖方: WIT MOLD LIMITED | Custom Plastic Molds molding Plastic Molds molding servicesprovide many extremely versatile part... | |

| Negative Pressure Physiotherapy Tank Molds | 卖方: Zhuozhou Yihua Mould Factory | The negative pressure tank is a disposable consumable for male negative pressure treatment. This ... | |

| PLC Casing Molds | 卖方: Zhuozhou Yihua Mould Factory | The PLC housingbelongs to a kind of rail electrical module. It not only needs to achieve the fit ... |