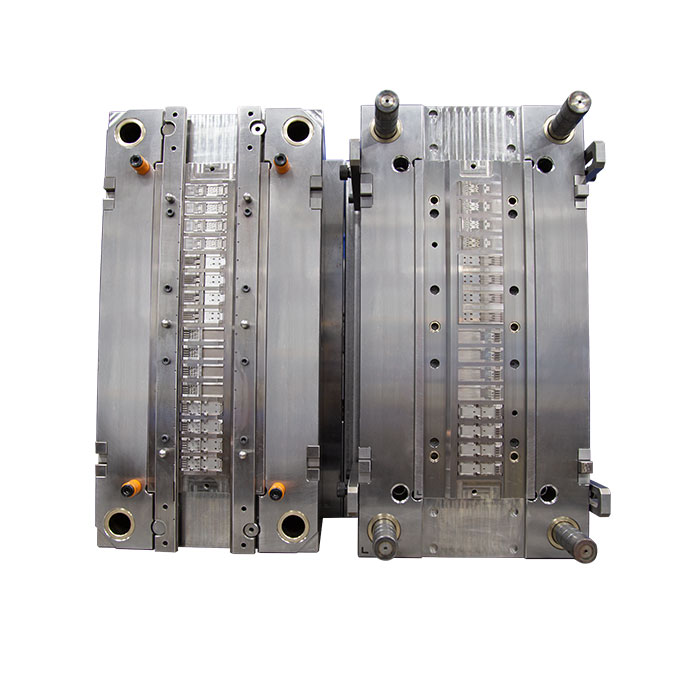

Automotive Mold

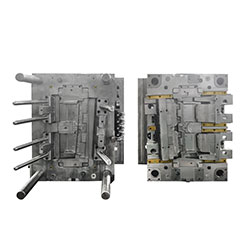

Large drop of automotive moldtop and bottom; The mold manufacturing technology is complicated; The injection system is many and complicated; The mold cost is ver high.

AUTOMOTIVE MOLD TYPES

Automotive AC Air Outlet

The air outlets of automotive AC are generally assembled by multiple parts, classified according to their functions and purposes: there are exterior molds, functional molds, or both exterior and functional molds.

Automotive Mold Manufacturers

With over 15 years of experience in automotive mold development and production, USM will make mold flow analysis from the DFM report step to ensure that the pressure will be controlled at a reasonable range during injection, and there are no weld marks and other defects on the part surface.

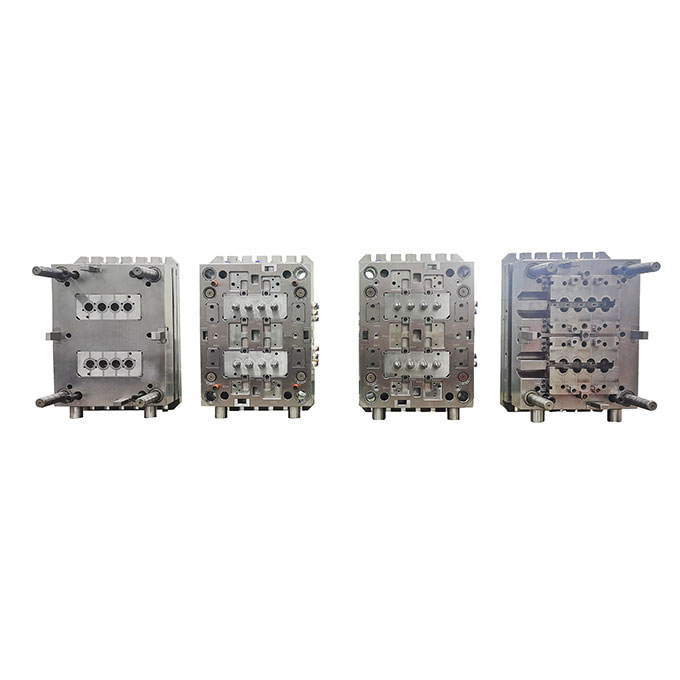

Automotive Grille Mold

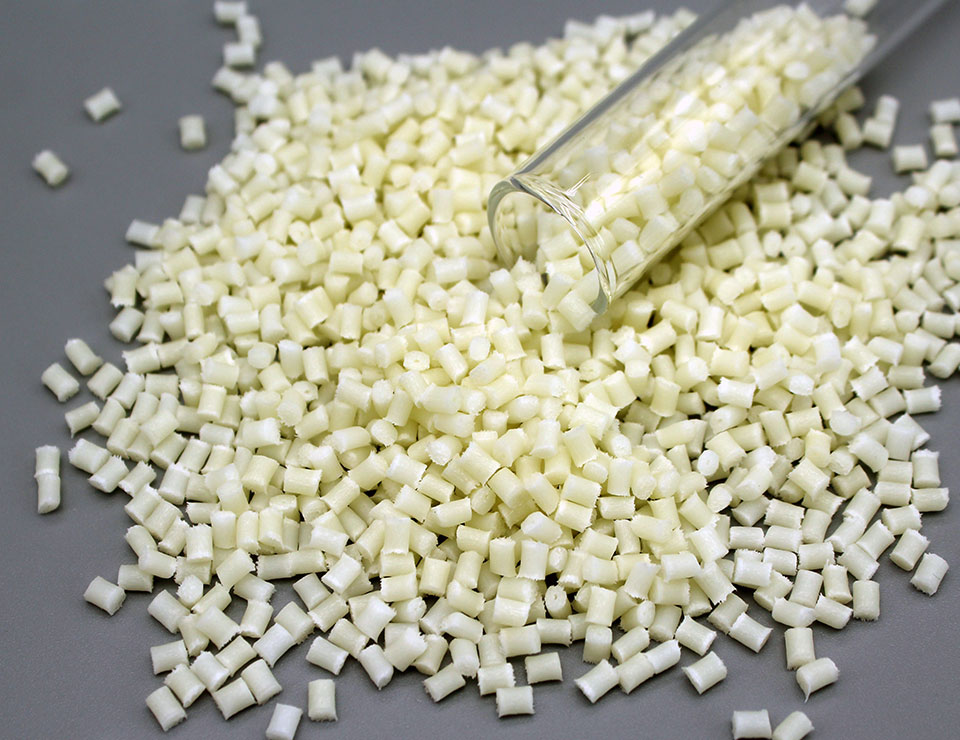

The part surface of the air intake grille generally has several treatment methods such as leather texture, sandblasting, paint spraying, and electroplating, the materials usually are PP, ABS, ASA, etc., and the surface of the bumper decorative grille is generally treated with leather texture and sandblasting, mainly PP material.

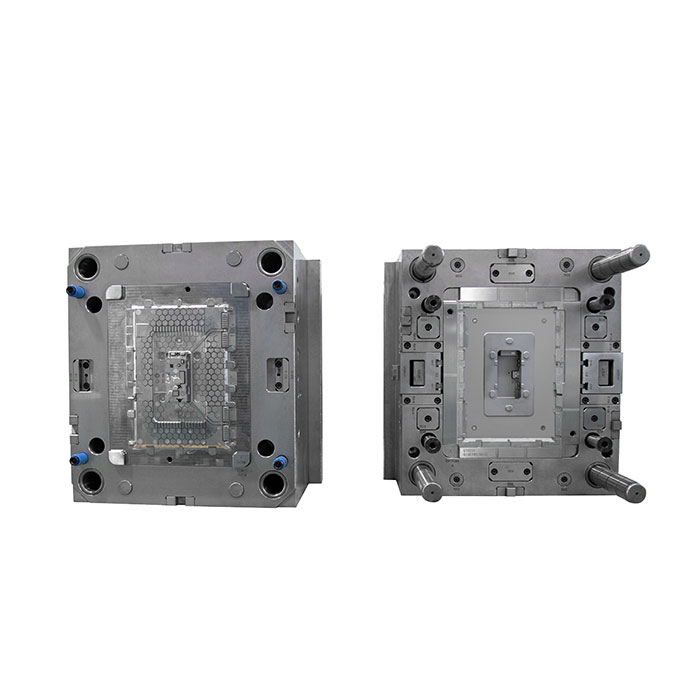

Automotive Door Mold

The plastic application in automotive is divided into interior parts, exterior parts, and functional parts. According to different material properties, plastics are usually divided into three types: general plastics, engineering plastics, and special plastics.

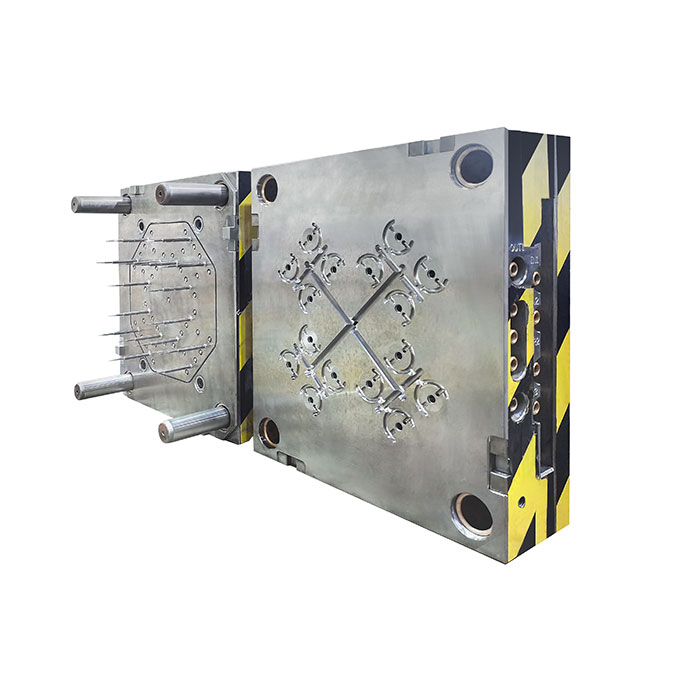

Auto Parts Mould

The automotive console is an external part in automotive interior parts, and no weld line on the part surface, the console's gating system generally uses a valve gate of hot runner system, the gate position usually has a direct injection gate on the non-critical surface which is to save plastic material, the shut-off area will be injected on side of the non-critical surface, or the middle area will be injected to the non-critical surface by the banana gate.

Automotive Molds Characteristics

If you want to know more about automotive mold technology, please visit our website.

As one of custom plastic mold manufacturers, we serve different industries, especially in the fields of water-assisted injection mold,gas injection mold, two-color mold (2k molds),multi cavity moldand pre-deformed mold with professional experience make us stand out in this industry.

Send product request

Other supplier products

| Auto Parts Mould | Auto Parts Mould Automotive Parts Moldfeatures: More kinds of molded automotive parts, please visit our website. As one of injection m... | |

| Drip Tip Mold | 810Drip Tip Mold 2k Electronic Cigarette Drip Tip Moldadvantages: plastic injection moldingcycle is short, suitable for large-volume prod... | |

| Voice Operated Switch Mold | Switch Plate Mold The function of the smart home system is extensible, so it can meet the demands of different users. For example, the user's smar... | |

| Medical Pipette Tip Mold | Medical Pipette Tips USM as a medical plastic mouldingsupplier provides products including medical device plastic parts, suction tips, blood colle... | |

| Metal Insert Mold | Metal Insert Molding Choosing suitable material and molding conditions, not only for products that are easily deformed and damaged (such as glass,... |

Same products

| Medical Plastic Parts | Seller: Packson Mold Co.,Ltd | Project Management To be a qualified medical plastic components manufacturer, the most advanced ... | |

| PA66 GF15 Heat Stabilized (A2006C, A2016C) for Engineering Plastics | Seller: Suzhou Anmei Material Technology Co., Ltd | PA 66 GF 15is a 15% glass fiber reinforced, heat-resistance, polyamide 66 resin for injection mol... | |

| PA66 GF | Seller: Suzhou Anmei Material Technology Co., Ltd | Anmei focuses on the production of modified engineering plastics. We have polyamide pa6 6gfmodif... | |

| Nylon6 PA6 | Seller: Suzhou Anmei Material Technology Co., Ltd | Other than fiber-reinforced pa6 polyamide, the unreinforced nylon type 6 produced by Anmei, one o... | |

| Nylon 66 Pa66 With High Tensile Strength (A2307X01, A2317X01) for Engineering Plastics | Seller: Suzhou Anmei Material Technology Co., Ltd | Using Polyamide 66 as the basic resin, the tensile strength of nylon 66 is obtained by blending a... |