Injection Molding Surface Finish

Injection Molding Surface Finish

Do not use the finest whetstone, sandpaper, or abrasive polishing paste at the beginning of mold polishing, as you can't throw away the rough lines. The living surface polished in that way looks very shiny, but when you take a side view, the rough lines appear. Therefore, it is necessary to polish from coarse whetstone, sandpaper or abrasive polishing paste, then change to finer whetstone, sandpaper or abrasive polishing paste for polishing, and finally polish with the finest abrasive polishing paste. This seems to be cumbersome and there are many processes. In fact, it is not slow. One process after another, the rough processing lines in the front are polished off, and then the following plastic injection molding chinaprocess step is carried out without rework, and the plastic injection molding surface finishcan meet the requirements with one step.

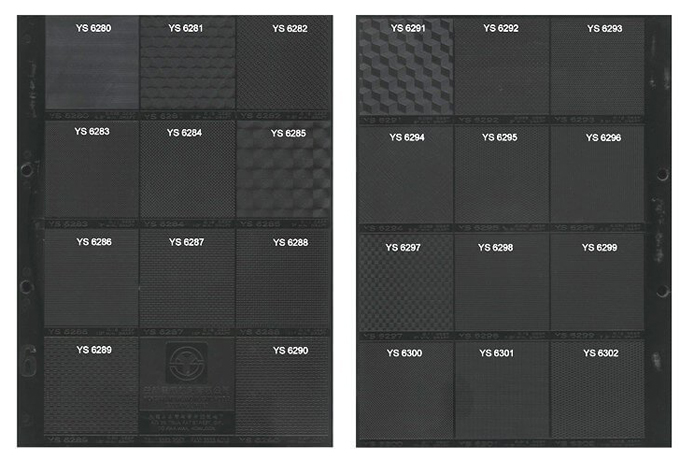

Textured Finish

Industrial injection molding finishingis to create various patterns on the surface of different metal products through the action of chemical potions, such as sand patterns, stripes, images, wood patterns, leather patterns and silk patterns. Different technical processes produce different texture styles.

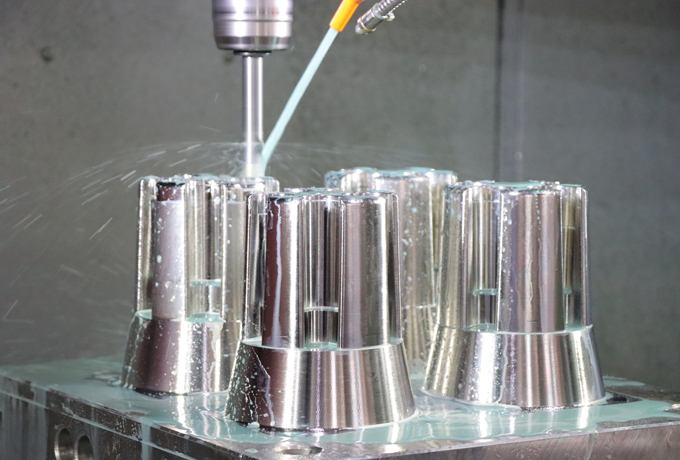

Polishing

Injection mold polishing has two purposes; one is to increase the smoothness of the mold, so that the surface of the product from the mold is smooth, beautiful and beautiful, and the other is to make the mold easy to demold, so that the plastic will not be stuck on the mold and cannot be taken off.

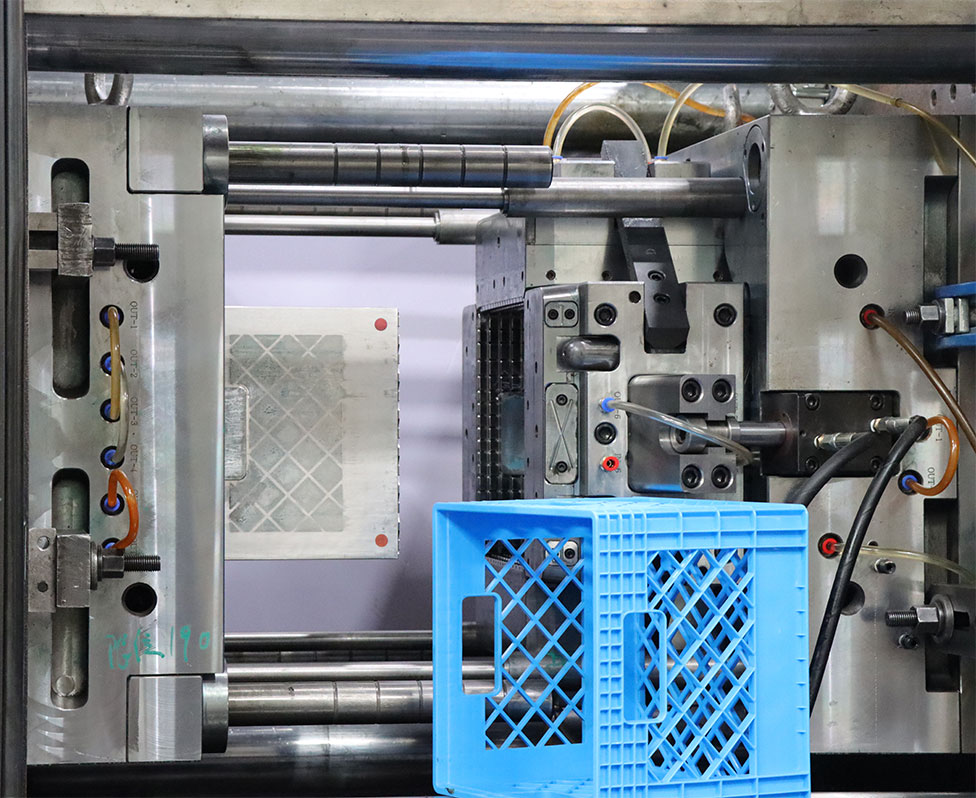

Sandblasting

Sandblasting is to shoot quartz sand to the surface of the mold through an air gun with a certain pressure, thereby forming a layer of frosted surface on the surface of the plastic mold design. When a plastic mold injects a product, it will form a matte effect on the surface of the product. Generally, sandblasting is divided into two types: fine sand and coarse sand. For sandblasting, the surface of the plastic part is easy to wear off.

We can provide different plastic surface finish typesfor sale, if you have needs to buy injection molding finishes, please contact us.

As a reliable plastic injection molding company, we will do our best to meet all the needs of customers.

在线联系供应商

Other supplier products

| Injection Mold Design Engineering | Injection Mold Design Engineering Injection mold engineeringis a procedure at the first stage of injection molding process, which develops the inj... | |

| Medical Injection Molding | Keyplast has efficient team with many years' experience of injection moulding, while medical industry is one of our mainly focused industries. With... | |

| Plastic Injection Mould Tooling | Plastic molds are tools that are matched with plastic mold makingmachines in the plastic processing industry to give plastic products a complete co... | |

| Injection Molding Surface Finish | Injection Molding Surface Finish Do not use the finest whetstone, sandpaper, or abrasive polishing paste at the beginning of mold polishing, as yo... | |

| Types Of Plastic Injection Mold Polishing | Types Of Plastic Injection Mold Polishing Introduction to the plastic injection mold polishing These days, industrial products are developing in ... |

Same products

| Two-Shot Injection Molds | 卖方: WIT MOLD LIMITED | Two-Shot Injection Molds Advantages of two-shot injection molding The benefits of Double Inject... | |

| precision injection molding | 卖方: WIT MOLD LIMITED | precision injection molding Precision injection moldingis a method demanding unparalleled accura... | |

| Custom Plastic Molds molding | 卖方: WIT MOLD LIMITED | Custom Plastic Molds molding Plastic Molds molding servicesprovide many extremely versatile part... | |

| Negative Pressure Physiotherapy Tank Molds | 卖方: Zhuozhou Yihua Mould Factory | The negative pressure tank is a disposable consumable for male negative pressure treatment. This ... | |

| PLC Casing Molds | 卖方: Zhuozhou Yihua Mould Factory | The PLC housingbelongs to a kind of rail electrical module. It not only needs to achieve the fit ... |