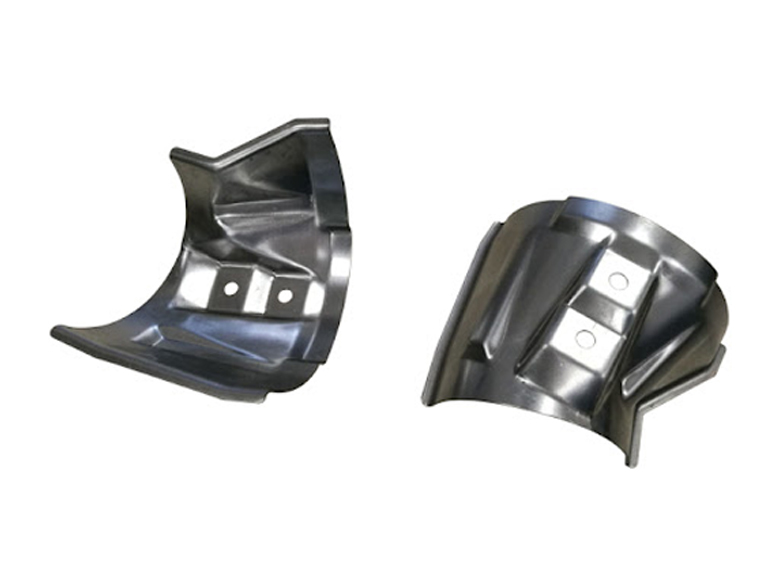

Stamped Sheet Metal Parts

Proto-mold purchased advanced large laser cutting machine 3 sets, Amada precision CNC bending machine 15 sets, heavy oil pressing machine 3 sets and riveting machine, hole pumping machine, tapping machine, drilling machine and other stamped sheet metal processing equipment.

Sheet oem metal stamping commonly used materials

galvanized steel plate SECC

The base material of SECC is general cold-rolled steel coil, which becomes electrogalvanizing product after continuous electrogalvanizing production line goes through degreasing, pickling, electroplating and various post-treatment processes. SECC not only has the mechanical properties and similar machinability of ordinary cold rolled steel sheet, but also has superior corrosion resistance and decorative appearance. In the electronic products, home appliances and furniture market has a great competitiveness and substitution. For example, SECC is commonly used in computer cases.

As one of stamped sheet metal parts manufacturers, we can offer sorts of metal sheet stamping parts for sale, if you have needs, please contact us.

China protomold company Proto Mold offers metal prototyping services for every industry, product prototype solutions for visual models and rapid prototype services for low volume & short-run production. And product prototype solutions include the Automotive, Medical, Aerospace, Robot. At Proto Mold, customers can manufacture your design with speed, agility, quality and proper protomold cost.

Other supplier products

|

|

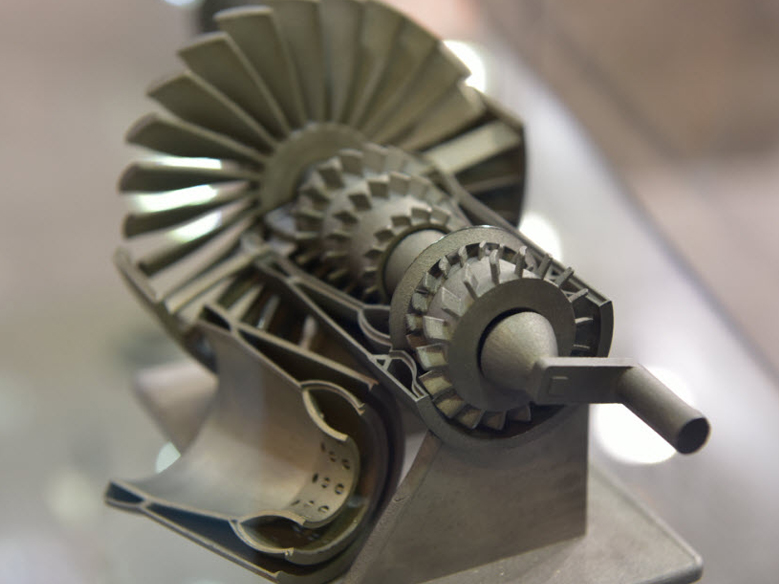

Stainless Steel Printing |

For parts with complex structure, stainless steel 3d printing service can realize integral printing forming, avoiding mass increase and potential q... |

|

|

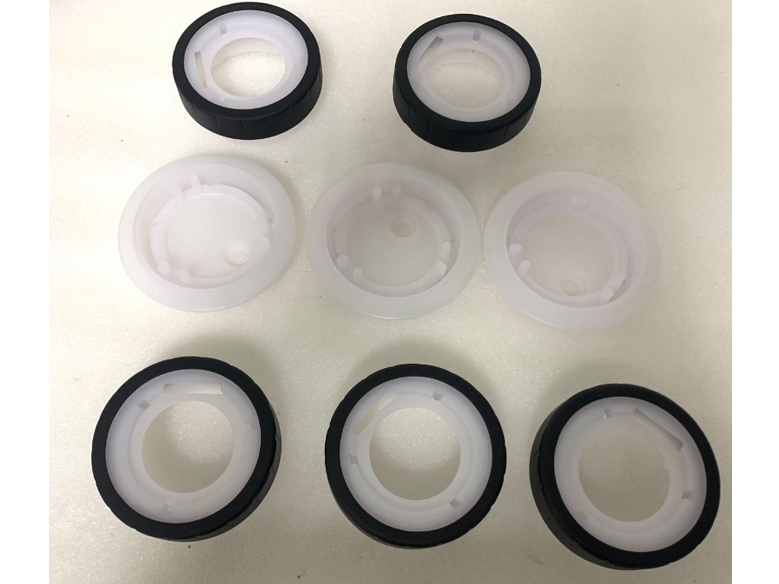

SLS Nylon Printing |

3D printed nylon parts can be used for product verification or directly used as functional products. The product is 3D printing with light weight a... |

|

|

Stamped Sheet Metal Parts |

Proto-mold purchased advanced large laser cutting machine 3 sets, Amada precision CNC bending machine 15 sets, heavy oil pressing machine 3 sets an... |

|

|

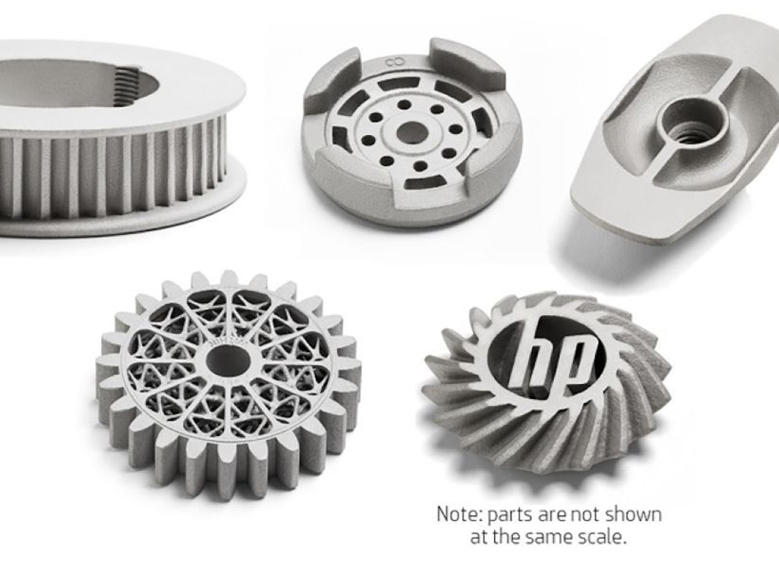

Titanium 3D Printing Service |

Titanium 3d printing servicefor Titanium alloy parts has very high strength, precise dimensions, and their mechanical properties are better than th... |

|

|

Stamped Sheet Metal Parts |

Stamped Sheet MetalParts

Proto-mold purchased advanced large laser cutting machine 3 sets, Amada precision CNC bending machine 15 sets, heavy oil ... |

供应产品

Same products