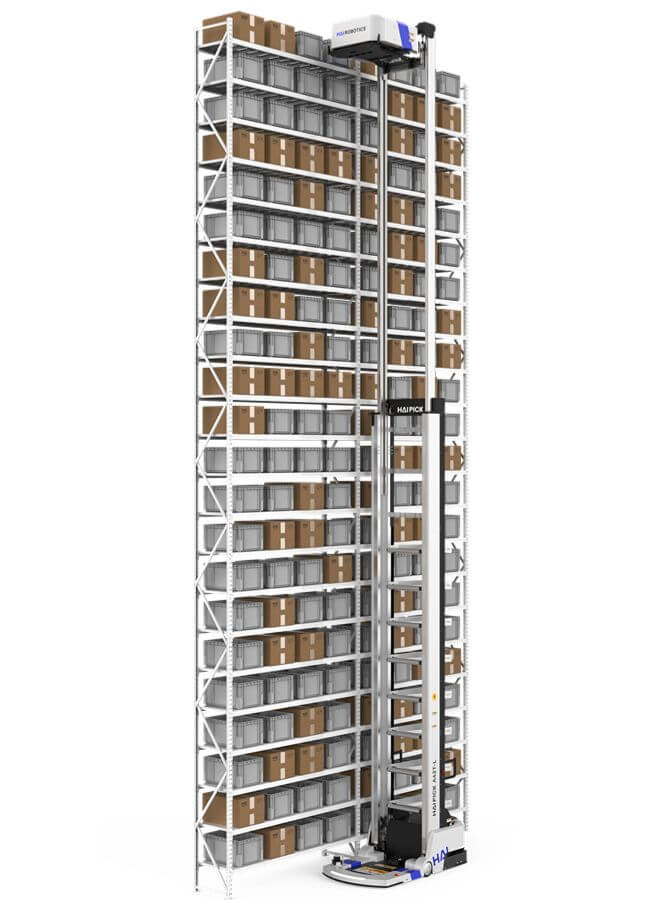

HaiPick A42

Multi-Layer ACR

HaiPick A42

The A42-series offers picking and storage of cases up to a height of 5.2m (17.1 feet). The series consists of four models which handle a wide range of case dimensions and types. Compatible plastic tote and carton box in different sizes.

High Efficiency: With multiple storage trays, our automated warehouse picking robot can handle up to 9 cases simultaneously. This greatly improves warehouse picking efficiency.

Flexible Payload Dimensions: The robot supports separate and mixed picking of plastic totes and carton boxes. The robot can handle a wide range of case dimensions and types.

Flexible and Scalable: Users can re-use existing racks and totes if they fit all requirements. Our automated warehouse picking system can also be easily deployed in a small part of the warehouse and scaled up to a bigger installation as the user's business grows.

Efficient Deployment: Our robotic warehouse automation system can help you rapidly automate your warehouse without impacting any running operations.

Product Safety: CE+NRTL certified.

Seeing is Believing

Video: Explore How HaiPick A42 Warehouse Robot Picker Works

The HaiPick A42 utilizes advanced robotics technology to streamline the storage and picking process in warehouses and distribution centers. This innovative robot is designed to navigate through narrow aisles and pick up items with ease, making it an ideal solution for businesses that require efficient and cost-effective robotics in warehousing solutions. Not to mention, our Haipick A42 robots work seamlessly with our robotic workstations, resulting in significant efficiency gains. To explore how the HaiPick A42 warehouse storage robots work, you can watch videos that showcase the robot in action.

Product Features

01 Autonomous & Intelligent Functions

Autonomous picking, handling, navigation, charging

02 Ultra-wide Picking Range

Covers a broader storage space range

03 Fast & Stable

Stable straight move speed and high stop accuracy in travel direction

04 Multi-case Handling

Each robot can store up to multiple cases at the same time

05 Wireless Communication

Supports Wi-Fi to ensure smooth operation

06 Multiple Safety Protection

Obstacle detection, active obstacle avoidance, anti-collision alarm, and emergency stop

07 Mixed Picking

Compatible with cartons/totes, multi-size cases

08 Flexible & Customizable

Supports different customization requirements including height and color

09 The Ideal Solution

Tailored specially to meet different application scenarios to deliver the best solution

Other supplier products

|

|

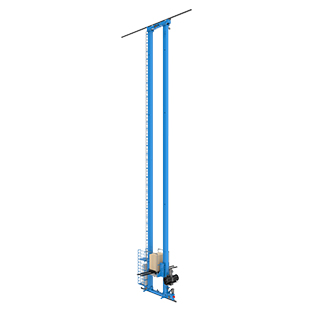

Telescopic Lift ACR |

HaiPick A42T

The HaiPick A42T Telescopic Lift ACR is the world's first ACR that can pick and store plastic totes and carton boxes at a dizzying he... |

|

|

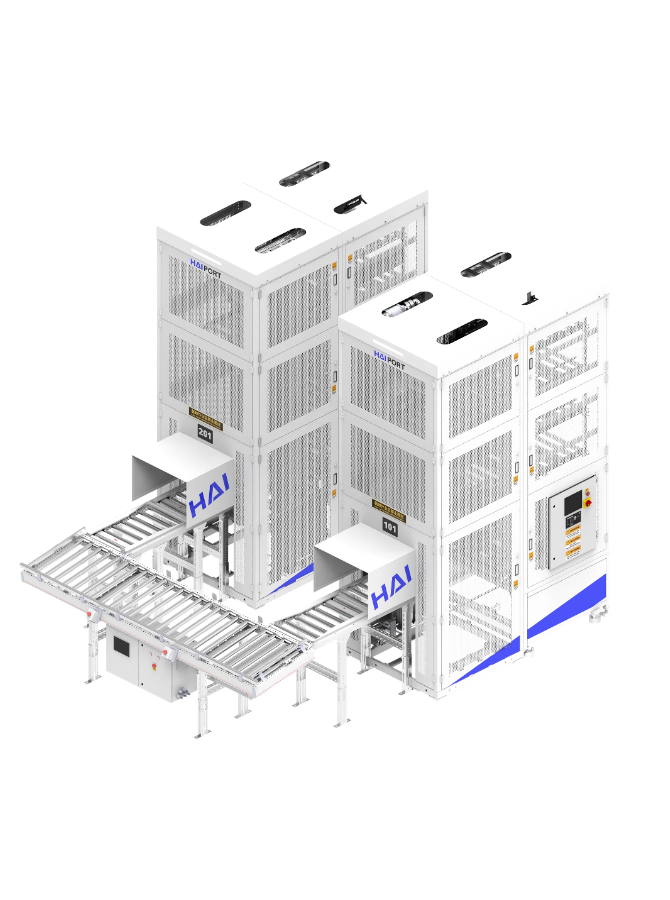

HaiStation |

In the complete Goods to Person solution, HaiPick robots are dedicated to improving transport efficiency from warehouse to workstation. Hai Robotic... |

|

|

Multi-Layer ACR |

HaiPick A42

The A42-series offers picking and storage of cases up to a height of 5.2m (17.1 feet). The series consists of four models which handle... |

|

|

Apparel Warehouse: Bosideng Moves from Manual to Automation with ACR System |

World's No. 1 down garment producer Bosideng has joined forces with Hai Robotics to transform its apparel warehouse from manual to automated. The a... |

|

|

HAIQ Software Platform |

The HAIQ Software Platform is a warehouse management system developed by HAI ROBOTICS based on warehouse automation & robotics. The system intr... |

供应产品

Same products