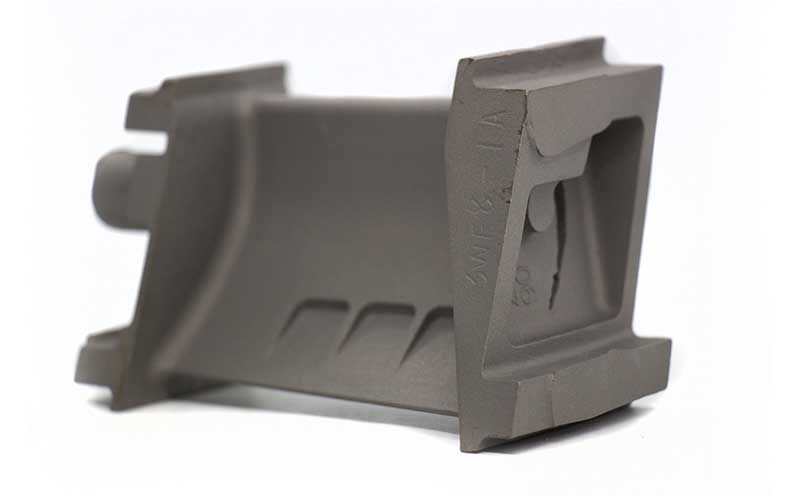

(Metal) Sand Casting

WALKSON is a steel sand casting foundry based in china, our melting furnace includes Electric Arc Furnaces(EAF) and Argon Oxygen Decarburization furnace(AOD), 6 meters diameter Quench tank which include the high-speed agitation system to improve the casting mechanical property (Charpy test and tensile result), except the advanced equipment. WALKSON, as a sand casting company in China, have an experienced engineering team to support our castings. With the professional technical support , Walkson success to earn a lot of customers from all over the world, help us to win-win together with our customers.

WALKSON can manufacture steel castings weight from 50kg-150000kg, rich experience on precision sand casting and heavy engineering components manufacture from method design to casting finish final machinings, such as Dragline walking frame, Dragline walking cam, drums, big sheaves and undercarriage components including tumbler, idler, trackpads(track shoes), high manganese wear parts, crusher parts, valve parts, pump parts, etc., our chemistry analysis(Gas level of Oxygen, Nitrogen, and Hydrogen optional), mechanical property testing(Tensile, Yield, Elongation, ROA, Impact @ambient or -196℃),standard comply with ASTM E1806, ASTM E23, ASTM E112, EN10045, EN10002, non-destruction test methods include Ultrasonic test(UT), Liquid Penetration test(PT), Magnetic particle test(MT), Radiographic inspection(RT), standard comply with ASTM E709, ASTM E165, ASTM E186, ASTM E446, EN1369, EN12680, EN12681etc., casting tolerance standard to comply with ISO 8062, surface finish standard SCRATA, MSS SP55, etc.

Our machining equipment is on top 3 level in china, we have:

- CNC machining center length(10.8m)×width(4.3m)×high(2.5m) 1 set

- CNC machining center length(6m)×width(3.5m)×high(1.8m) 1 set

- CNC floor milling and boring machine length(10m)×width(5m) 1 set

- CNC floor boring machine length(15m)×width(4.5m) 1 set

- CNC Vertical Lathe high(3.2m) ×diameter(5m

Alkline Phnolic Resin Sand Casting

Alkline Phnolic Resin sand can produce good surface finish, high dimensional standard steel castings which widely used in the sand casting foundries, suitable for manufacturing from 100kg casting to 20-ton casting, 30ton casting, max weight 80ton casting per pc.

Furan Sand Casting

Furan sand casting with good surface finish, high dimensional standard steel castings which widely used in the sand casting foundries, suitable for manufacturing from 200kg casting to 20-ton casting, 30ton casting, max weight 80ton casting per pc.

Water Glass Sand Casting

Water galss sand casting with good surface finish, high dimensional standard steel castings which widely used in the sand casting foundries, suitable for manufacturing from 200kg casting to 20-ton casting, 30ton casting, max weight 80ton casting per pc.

Vacuum Sand Casting

Vacuum sand casting is a casting process in which metals are melted, poured and crystallized in a vacuum chamber. Vacuum casting can minimize the gas content in metal and prevent metal oxidation.

Gravity Sand Casting

Gravity sand casting Gravity casting refers to the process that molten metal is injected into the mold under the gravity of the earth. With good surface finish, high dimensional standard steel castings which widely used in the sand foundries.

Iron Sand Casting

Iron sand casting can produce good surface finish, high dimensional standard steel castings which widely used in sand casting foundries.

Aluminum Sand Casting

Aluminum sand casting is a kind of pure aluminum or aluminum alloy equipment which is produced by casting. Generally, the liquid aluminum or aluminum alloy heated by sand mold or metal mold is poured into the mold cavity, and the aluminum parts or aluminum alloy parts with various shapes and sizes are usually called aluminum die castings.

Brass Sand Casting

Brass sand casting is a method which melt the brass and add other alloy into the melt metal, pouring the metal into the mold to making brass casting and brass alloy casting. Widely used in the world and all kinds of fields.

Steel Sand Casting

Steel sand casting is a method which melt the scrap and add other alloy into the melt metal, pouring the metal into the mold to making steel casting and alloy steel casting.

Stainless Steel Sand Casting

Stainless Steel sand casting is a method which melt the scrap and add other alloy into the melt metal, pouring the metal into the mold to making stainless steel casting. Cast stainless steel is a kind of cast steel which can resist environmental corrosion.

WALKSON Steel Casting Advantage

WALKSON steel casting foundry had been working on steel casting for decades, we manufacture low alloy steel casting, stainless steel casting, etc..

Firstly, WALKSON have advantaged equipment for sand mould casting process. We have 2 sets EAF(Electric Arc Furnace) and one set AOD(Argon Oxygen Decarburization Furnace) for our metal refining, which can produce higher purity of molten steel, secondary the EAF(electric arc furnace uses scrap steel as the main raw material, so the electric arc furnace steelmaking can reuse the alloy elements in the scrap steel, this 2 area will absolutely ensure WALKSON steel casting have high-level quality castings and reduce the sand casting cost to buy high-quality scrap metal which benefits our customers on the cost but the quality is on the top level of our casting. With the electric arc furnace and argon oxygen decarburization furnace, we are on the top level in china's sand casting foundry.

Secondary our steel casting Heat treatment furnace and quench tank (with the stirring system) which can ensure our steel casting manufacturing process can reach high stand mechanical property, include Charpy test, tensile test, and hardness test, with this equipment, our sand casting factory can produce high-level steel castings and improve the casting life a lot.

Thirdly, we are certificated with ISO9001, ISO14000, ISO18000, and invest a lot of environmental protection equipment to our sand casting foundry which approved by the government which ensures we will never stop manufacturer all the year, banish our customer's worries that many sand casting foundry will shut down a few months in a year which will keep our delivery time on time.

Lastly, our people are professional in technical and quality control, and are familiar with types of sand casting process. We control every process, from molding, melting, pouring, knockout, HT(heat treatment, include annealing, quench, temper), UT, MT, Final machining, we always have our QC people onsite witness and technical support ensure 100% good quality steel castings are manufactured and delivered to our customer.

With the advantaged equipment, different sand casting types, top-level casting quality and 98% delivery on time, WALKSON will be your first choice.

START NOW

Email us with any questions or inquiries or use our contact data. We would be happy to answer your questions.

What's New in Walkson

what kind of sand is used for metal casting? sand casting is which of the following types of casting process? WALKSONis a professional sand casting factory, we provide sand casting china, sand casting report pdfand etc. Want to know sand casting working principle, sand casting sand typesor sand mould casting process? Please contact us.

在线联系供应商

Other supplier products

| Shredder Hammer Tips/ Knife Edges | Our shredder hammertips are bi-metallic composites having 700BHN hardness and available in various sizes and shapes. Our products are widely use... | |

| Manganese Liners | Manganese Liners Crusher is the main equipment in crushing process of various kinds of ore and bulk material, which is widely used in mining, metal... | |

| Dragline Walking Frame | Dragline walking frame or walking arm, together with walking cam and cam shaft / propel shaft are the most important parts for dragline walking mec... | |

| Bubble Shaft | WALKSONcan provide forged shafts, forged Crankshafts and forged stepped/bubble shafts of carbon steel, alloy steel, stainless steel, titanium, nick... | |

| Bucket Wear Products | Bucket WearProducts WALKSON provides professional wear solution and a whole set of wear-resistant products. The products including: Chokey wear... |

Same products

| 便携式木枕木 钻孔机 | 卖方: 武汉联科瑞际轨道设备有限公司 | ||

| Установки нанесения двухкомпанентного клея Установка для нанесения клея | 卖方: 824681 | Большой ЖК-экран CAD-файл может быть импортирован и превращен в шаблоны выдачи, а также загружен... | |

| Inconel alloy Superalloy CNC Machining Services | 卖方: 新航金属制品有限公司 | 英科乃尔合金高温合金 CNC 加工服务简介 英科乃尔合金是一类高性能镍基高温合金,以其出色的强度、抗氧化性和耐高温环境能力而闻名。这些材料广泛应用于航空航天、发电和化学加工行业,这些行业的部件必... | |

| Titanium Alloy 3D Printing Prototyping Service | 卖方: 新航金属制品有限公司 | 钛合金 3D 打印原型服务简介 钛合金因其出色的强度重量比、出色的耐腐蚀性和在高温环境下的出色性能而受到广泛认可。这些特性使其成为航空航天、医疗、汽车和船舶行业中性能和耐用性至关重要的关键应用的... | |

| Eaton Fuller 4300902 Tapered Roller Bearings 53.98×95.2x34mm | 卖方: 海双机械有限公司 | Bearing Technical DataModel:4300902Structure:Tapered Roller BearingsInner diameter(mm):53.9... |