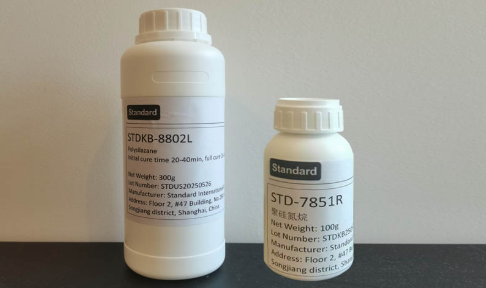

Colorless transparent liquid STD-8833

Basic Information

Colorless Transparent Liquid 8833 is a high - performance material widely used in various industrial applications due to its unique properties.

Chemical Properties

| Property | Value |

|---|

| Appearance |

Clear to pale yellow liquid |

| Flash Point |

<21℃ (68.9℉) |

| Viscosity |

50-200 mPa·s @20℃ (68℉) |

| Specific Gravity |

0.995-1.005 g/cm³ |

| Resin Content |

100% |

Application Matrix

| Application | Description |

|---|

| Coatings |

Used for protective and decorative coatings |

| Adhesives |

Provides strong bonding for various materials |

| Pre - ceramic polymers |

Acts as a precursor for ceramic materials |

| Polymer Matrix Composites (PMC) |

Enhances the properties of composite materials |

| Non - flammable composites |

Offers flame - retardant properties |

| Organic/Inorganic hybrids |

Combines the benefits of both organic and inorganic materials |

| Casting elastomers |

Used for casting flexible and elastic parts |

| Rigid castings |

Suitable for creating rigid and durable components |

Curing Performance Pre - Curing Properties

| Property | Value |

|---|

| Appearance |

Colorless transparent liquid |

| Post - Cure Density |

1.6 - 2.0 g/cm³ |

| Viscosity @20℃ |

50 - 200 cPs |

| Film Thickness |

0.5 - 20 μm |

Curing Methods

| Method | Time |

|---|

| 23℃/50% RH |

1 - 3 days |

| 100℃ |

2 hours |

| 200 - 300℃ |

10 - 30 minutes |

Curing Behavior

Performance depends on ambient temperature/humidity.

| Film Thickness (μm) | Application | Tack - Free (min) | Hardness (ASTM D3363) | Adhesion (ASTM D3359) |

|---|

| 7 - 15 |

Troweling |

25 - 30 |

6H |

5B |

| 25 - 35 |

Brushing |

25 - 30 |

7H |

5B |

| 24 - 37 |

Spraying |

25 - 30 |

7H |

5B |

Post - Curing Properties (30℃/55% RH on Q - panel steel)

| Property | Result |

|---|

| Tinplate Adhesion |

5B |

| Wafer Adhesion |

5B |

| Stainless Steel Adhesion |

5B |

| Aluminum Alloy Adhesion |

5B |

| Glass Adhesion |

5B |

| Ceramic Adhesion |

5B |

| Pencil Hardness |

5 - 7H |

| High - Temp Resistance |

800℃ |

| Salt Spray Resistance |

2.400hrs passed |

| QUV Aging |

3.000hrs passed |

Mechanical Properties

| Property | Value |

|---|

| Tensile Strength |

20 - 30 MPa |

| Elongation at Break |

10 - 20% |

| Flexural Modulus |

1.500 - 2.000 MPa |

| Impact Resistance |

2 - 3 kJ/m² |

Environmental Resistance

| Property | Value |

|---|

| UV Resistance |

3.000 hours exposure without significant degradation |

| Chemical Resistance |

Resistant to common solvents and acids |

| Water Resistance |

Immersion in water for 1.000 hours without significant change |

Other supplier products

|

|

Fabric Surface Combustion Performance Tester ISO 10047:1993 GB/T 8745-2001 |

Standards:

For different standards, different accessories are required . GB/T 8745-2001 Textile. Combustion performance. Determination of surface ... |

|

|

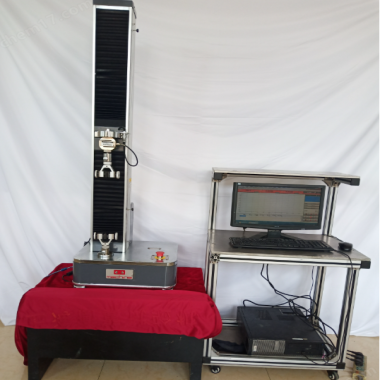

Automotive Bed Liner Strength Testing Machine |

Standard

ASTM D624(Standard Test Method for Tear Strength of Conventional Vulcanized Rubber and Thermoplastic Elastomers)

ISO 37(Rubber, Vulcaniz... |

|

|

Snap Button Tester |

Testing Standards:

ASTM D7142-2/F963, CFR 1500, EN 71 PART 1, GB 6675, ISO 8124, M&S P115A

Applications:

Snap Tester is used to evaluate t... |

|

|

Paper dust meter |

Product Information:

Paper dust meter is suitable for measuring the dust degree of paper or cardboard, books, toilet paper, tissue paper, etc.

... |

|

|

Sample cutter 100cm |

Sample cutter 100cm - Other test instrument - standard

Standards:

Applications:

The application of sharp cutter wide. Even difficult mat... |

供应产品

Same products

|

|

Easy-cleaning Silicone-Modified Waterborne UV Resin |

卖方: Guangzhou Human New Material Science and Technology Co., Ltd |

LUV533 is a high-performance, silicone-modified hexafunctional waterborne UV resinengineered to d... |

|

|

Water-based Soft-Touch Resin for Consumer Electronics |

卖方: Guangzhou Human New Material Science and Technology Co., Ltd |

Water-based Soft-Touch Resinis an advanced coating material formulated to deliver a luxurious, ve... |

|

|

Conformal Coatings |

卖方: Guangzhou Human New Material Science and Technology Co., Ltd |

The conformal coatingsprovide good adhesion to metal, PCB and other substrates after curing at ro... |

|

|

Metalized & Laser Transfer coating |

卖方: Guangzhou Human New Material Science and Technology Co., Ltd |

Metallized and laser transfer coatingsare designed with sustainability in mind, ensuring minimal ... |

|

|

Hydrophilic coatings for Air Conditioner |

卖方: Guangzhou Human New Material Science and Technology Co., Ltd |

A water-based coating combination applied on the surface of aluminum foil, which forms a layer wi... |