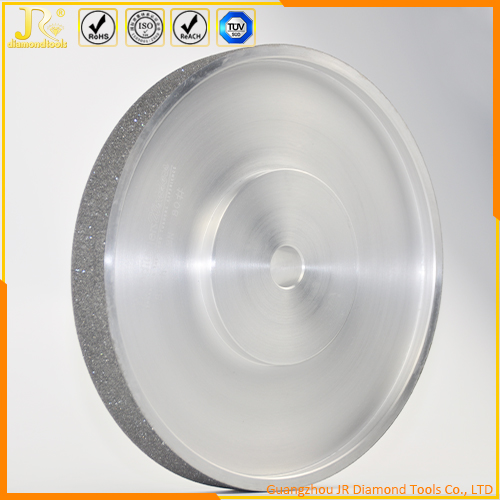

Electroplated Diamond / CBN Grinding Wheel

Electroplated grinding wheels with nickel bonding can achieve high stock removal rates and high-precision profiles on parts being ground. Depending on the wheel blank design, plating technique, and post-treatment of the single-layer grit structure, many different grinding wheels can be produced using this bond system. There is no need for dressing during the life of the wheel. This avoids downtime and eliminates the need for a dressing device.

Electroplated Diamond / CBN Wheel

Electroplated wheels are noted for relatively large grit protrusion and higher abrasive concentration. This results in very free cutting properties and in high stock removal capacity.Besides, these tools are noted for:1. Allow special shapes and profile tools to be made at short notice.2. Cause very little change on wheel shape after used, suitable for precision grinding.

Electroplated grinding wheels are and excellent option when an aggressive amount of stock removal is required.

A single, uniform layer of diamond or cubic-boron-nitride crystal is electroplated to a precision machined steel surface.

The electroplating process gives the most aggressive, open structure of all bonding methods. This bond type is primarily used in from grinding applications.

*All bonds can be fashioned into any standard or custom shape*

Benefits of Electroplated Wheels:

Aggressive / free cutting bond structure adapts to various spindle speeds

Ability to grind a particular shape or profile

Increased productivity

Improved grind ratios

Our diamond plated wheels offer many advantages over other options, including a more aggressive bond, lower initial costs, high performance and long-lasting durability for extended usage. Our custom enhanced plating guarantees superior performance, and ensures that our plated products are able to maintain both their original shape and dimensions for a longer working life. The result is a much freer and faster task action and completion.

Electroplated Diamond or Cubic Boron Nitride (CBN) products have a single layer of abrasive held by a tough, durable nickel alloy. Unlike sintered (metal bond) or resin bond Diamond or CBN products in which the abrasive diamond particles are buried in the bond and held together by a metal or resin binder, electroplated products allow the diamond particles to protrude from the surface for maximum abrasive particle exposure. Experience freer, faster cutting action with minimum heat generation.

Electroplated Diamond or CBN products are able to retain their original shape and dimensions throughout their working life. Electroplating allows abrasive particles to protrude from the bond matrix, providing a free, faster cutting action with minimum heat generation.

Electroplated Diamond Tools provide:

Free Cutting ActionBetter removal rates and less heat/thermal damage to the part when an aggressive amount of stock removal is required.

Excellent Form Holding CharacteristicsHolds tolerance and simple and intricate shape and forms for the entire life of the tool or wheel, from first grind to last.

Maximum Abrasive Particle ExposureGives the most aggressive, open structure of all bonding methods.

High Stock/Material Removal RatesWith faster stock removal and increased speed and feeds, lower your long-term cost with the potential reduction or elimination of time associated with setup, dressing, and tool changes.

ReusableStrip and replate services available with potential savings of 40% over new electroplated products.

Application and Processing Material for Electroplated Wheel

Jig grinding: Mostly used in fined ceramics processing and precision grinding for quartz. Customized items are also provided to cater your needs. Common grit size is #80~#325.

Touchscreen Processing: Drilling and chamfering for the glass panel of the smart and tablet computer. We could also combine different grit sizes in the same diamond mounted point.

Grinding for Cutting tools: Normal end-mill grinder and drill grinder go with electroplated wheel. Carbide can be ground by diamond wheel and High Speed Steel could be ground by CBN wheel.

Precision grinding: Electroplating can produce wheel of different shapes without deforming it. Therefore, it is suitable for precision grinding or rimming aluminum oxide wheel.

在线联系供应商

Other supplier products

| Saucer type grinding wheel | 12V9 diamond grinding wheel used for sharpening and finishing of cutting tools back surface. *The abrasive layer of the grinding wheel can be made... | |

| CBN Grinding Wheel | Cubic Boron Nitride(CBN) grinding wheels are a revelation for the sharpening of HSS turning tools. CBN abrasive is a similar product to synthetic i... | |

| Vitrified diamond grinding wheels | Vitrified diamond grinding wheels are a kind of circular bonded abrasive with through-hole in the center which made of diamond powder and vitrified... | |

| Vitrified CBN Grinding Wheel for Camshaft | Description:Vitrified bond CBN Grinding Wheel is suitable for grinding the cam lobes of automobile camshafts.The wheel speed is 80m/s-160m/s,Design... | |

| 12A1 vitrified bond diamond and CBN grinding wheel | Introduction: Vitrified bond diamond grinding wheels possess pretty high abrasive resistance,especially in polishing hard and brittle work-piece. ... |

Same products

| HM Pumex Grinding Machine | 卖方: Shenzhen JuYongNeng Technology Co., Ltd | HM Pumex Grinding Machine Product Description Name TSP HM3/6-75 S/Z... | |

| XZZ Z1 Pro 电动研磨笔 IC 抛光工具 | 卖方: 深圳维客修科技有限公司 | XZZ Z1 Pro 电动抛光笔,配备多种磨头,满足不同类型的手机主板 CPU IC 研磨和维修需求。2025 XINZHIZAO XZZ USB 充电式抛光研磨笔,适用于手机维修。 XZZ ... | |

| Scraper Grinding Machine | 卖方: Kunshan Dekaisheng Edge Mold Co.,Ltd | Usage: Our commpany develops and produces fully automatic and speed adjustable blade grinder with... | |

| IC抛光用小型电动研磨笔 | 卖方: PHONEFIX technology Co.,Ltd | 描述E288-02小型手持研磨机迷你主板CPU IC抛光笔雕刻工具。电动研磨笔适用于手机维修,IC CPU抛光,玉石玛瑙,核雕,木雕,研磨铝板,印刷电路板和环氧板以及手机液晶屏残留OCA胶去除。... | |

| 250mm 10 Inch Diamond Grinding Plates For Concrete | 卖方: Xiamen ChinShine Industry and Trade Corporation | ChinShine designed this new style China diamond grinding shoe was perfect for grinding concrete, ... |