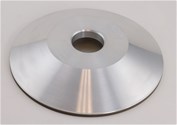

CBN Grinding Wheel

Cubic Boron Nitride(CBN) grinding wheels are a revelation for the sharpening of HSS turning tools. CBN abrasive is a similar product to synthetic industrial diamonds, but a CBN wheel is far better suited for sharpening high speed steels and will withstand the friction from grinding with much less heat produced than with a diamond wheel. They produce hardly any sparks, cut quickly and efficiently and will last for many years. Plus, because it will withstand the friction the wheel doesn't wear and therefore the jig will not need to be reset. No dressing is required and they leave a nice fine and even sharp edge.

What is a CBN Grinding Wheel?

ACBN wheelis made from cubic boron nitride. This material is one of the hardest materials available, second only to diamonds. The main feature of the material is that it features a high abrasion resistance and thermal conductivity that maintains its sharp cutting edges. It’s a great choice when doing advanced products that require a high attention to details.

Why Use This Type of Wheel?

CBN wheels are important for grinding HSS. This is because it's a better material for sharpening and for durability, one of the best available. Diamond is harder than CBN, but over time many people have discovered that diamond is not a suitable abrasive grain and isn’t a good choice when grinding on high speed dry wheels. Choosing to buy grinding wheels with cubic boron nitrate will offer you the durability you need, while giving you the finished product you desire.

Grain Size Selection Of CBNGrinding Wheel:

|

Grain Size |

Machining Type |

Application |

|

(80#, D181), (100#, D151),(200#,D76),(230#,D64) |

Rough |

Regrinding A Blade Edge Profiling And Sharpening Of Much Worn Inserts |

|

(1000#,D15),(1200#,D15B) |

Universal |

Standard Grain Size-Can Also Getting A High Sharpening Efficiency, Good Quality Machined Surfaces . |

|

(1500#, D15A),(2000#,D10) |

Finish |

Finishing Grinding – Getting A Very Good Quality Of Machined Surfaces. |

|

(4000#, D3) ,(5000#,D2) |

Super Finish |

Super Finish Grinding – Getting A Brilliant Quality Of Machined Surfaces. |

Benefits of CBN Grinding Wheels

These types of wheels have an almost indefinite life span when they are properly cared for. Many have chosen to use these wheels instead of the normal granular wheel because of their durability. The strong nature of the wheels comes from the bonding that takes place between the grains and the supporting steel hub. Thanks to this bonding feature, the wheels can be used dry without any coolant. Only a small amount of pressure is needed to sharpen a tool. The grind is very fine and there are almost no sparks when used for sharpening, unlike similar grinding wheels. The wheel remains cooler than a conventional wheel as well, making it nearly impossible to burn the tools.

在线联系供应商

Other supplier products

| Saucer type grinding wheel | 12V9 diamond grinding wheel used for sharpening and finishing of cutting tools back surface. *The abrasive layer of the grinding wheel can be made... | |

| resinoid bonded grinding wheels | The industrial Revolution was a catalyst in the rapid and gigantic growth of the auto and heavy machinery industries. As more and more "difficult-t... | |

| cnc grinding wheel | JR diamond toolsis an experienced manufacturer of High QualityDiamond and CBN grinding wheels.JR diamond tools companysupplies the wheels for sever... | |

| Diamond and CBN Face Grinding Wheels | Diamond and CBN Face Grinding Wheels for Roughing and Finishing Face grinding in through-feed processes with diamond and CBN grains has firmly e... | |

| Vitrified CBN Grinding Wheel for Camshaft | Description:Vitrified bond CBN Grinding Wheel is suitable for grinding the cam lobes of automobile camshafts.The wheel speed is 80m/s-160m/s,Design... |

Same products

| Motorcycle Body and Frame Plastic Mold | 卖方: Taizhou Huangyan Jingnan Moulding Co., Ltd. | As a key component mold professionally manufactured by Jingnan Mould, motorcycle body frame plast... | |

| For 2017 Audi A7 Rear Bumper Mould | 卖方: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Mould Name Audi A7 Car Bumper Mould Material PP+EPDM(Contraction: 1, 5%) Bumper Size 1800*510*460... | |

| For Mercedes-Benz-C-206 Modified Bumper Mould | 卖方: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Taizhou Huangyan Chenpeng Mold Co., Ltd. is a professionalwholesale Mercedes-Benz-C-206 Modified ... | |

| Front Bumper Lower Lip Mould | 卖方: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Introducing the for 2021 Honda CRV Front Bumper Lower Lip Mould: Elevate Your Driving Experienc... | |

| Bottle cap mold | 卖方: Taizhou Huangyan Yongsheng Mould Co., Ltd. | Taizhou Yongsheng Mould Co., Ltd. can produce cap moulds ()within 64 cavities. The hot runner or ... |