Cement Rotary Kiln

Since 1950s, CIC rotary kiln manufacturerhad started manufacturing of pyro processing equipment. These series of pyro processing rotating kiln equipment were used in various fields, that enforce us to overcome many difficulties. Nowadays, our rotary kiln in cement industry meets the incineration requirements of this equipment for various materials. The complete sets of the pyro processing heavy equipment and machinery CIC rotary kiln manufacturer can provide includes the dry, semi-dry and wet-processed cement rotary lime kiln, self-return soda steam calciner, metallurgy rotary kiln, environmental dryer and cooler, etc which are widely used in the industries of cement producing, metallurgy, chemical, environment protecting and ,etc.

Design of Rotating Kiln

Shell: Kilned carbon steel and alloy steel shell by automatic welding.

Supporting Device: Advanced spindle with automatic temperature measuring device and electronic heater unit.

Tyre and Roller: Made of ZG35CrMo steel and 42CrMo steel.

Driving Device: Rotary lime kiln is equipped with the reducer with the hard tooth surface and flexible diaphragm coupling, by continuous current dynamo or variable-frequency and variable-speed motor.

Kiln Seal Device: Different types of the seal are designed to match the needs.

Low-speed driving device is equipped.

Available for hazardous waste incineration such as chemical waste incinerator and industrial waste incinerator. In addition, fertilizer coolerand fertilizer granulator are also in the custom options.

What are the Design Parameters of Rotating Kiln?

Raw material

Inlet and outlet temperature

Size of rotary kiln

Processing capacity

Scope of supply

How to Stabilize Kiln Temperature in Summer and Keep the Production?

The heat transfer modes of high-temperature gas in a kiln to kiln skin are radiation heat transfer and convection heat transfer;

There is only conduction heat transfer among kiln skin, kiln brick and kiln shell;

There is only convective heat transfer between the outer wall of the kiln and the surrounding environment;

The kiln skin is in close contact with the refractory brick, that is, the temperature of the kiln skin at the contact position is the same as that of the brick;

The firebrick is in close contact with the rotating kiln body, that is, the temperature of the firebrick at the contact part is the same as that of the kiln body;

The inner surface temperature of the cement rotary kilnis the same as the outer surface temperature (the thickness of the kiln is ignored).

Technical Parameters of Rotating Kiln

Technical Parameters of Steam Calcination Kiln for Sodium Bicarbonate with Inner Recycling Of Soda

|

Specification |

Capacity |

Design Pressure(Mpa) |

Design Temperature(℃) |

Work Pressure(Mpa) |

Work Temperature(℃) |

||||

|

m |

t/d |

Tube |

Shell |

Tube |

Shell |

Tube |

Shell |

Tube |

Shell |

|

φ2.5×27 |

400 |

Normal Pressure |

270 |

200 |

Normal Pressure |

238 |

200 |

||

|

φ2.8×27 |

520 |

Normal Pressure |

270 |

200 |

Normal Pressure |

238 |

200 |

||

|

φ3×30 |

660 |

Normal Pressure |

270 |

200 |

Normal Pressure |

238 |

200 |

||

|

φ3.2×32 |

800 |

Normal Pressure |

270 |

200 |

Normal Pressure |

238 |

200 |

||

Technical Parameters of Steam Calcination Kiln for Sodium Bicarbonate with Inner Recycling Of Soda

|

Specification |

Heat Exchange Area |

Installation Inclination |

Main Motor Power |

Speed Rate |

Main Drive |

Slow Speed Drive |

Net Wt. |

Max Wt。 With Filler |

Product Features |

|

m |

M2 |

% |

kw |

r/min |

r/min |

r/min |

kg |

kg |

|

|

φ2.5×27 |

≥2500 |

2 |

160 |

980 |

7 |

198000 |

250000 |

Light Soda Ash |

|

|

φ2.8×27 |

≥3100 |

2 |

160 |

1480 |

228000 |

270000 |

Light Soda Ash |

||

|

φ3×30 |

≥3600 |

2 |

220 |

1480 |

300800 |

350000 |

Light Soda Ash |

||

|

φ3.2×32 |

≥4000 |

2 |

310 |

1480 |

350000 |

395000 |

Light Soda Ash |

Technical Parameters of Steam Calcination Kiln for Sodium Bicarbonate with Inner Recycling Of Soda

|

Specification (m) |

Basic Parameters (Speed Rater/min) |

Inclination (%) |

Capacity (T/d) |

Main Motor Power(kw) |

Thrust Type |

Support Type |

Weight (t) |

Remarks |

|

|

1 |

Φ3.2×50 |

1000 |

160 |

Hydraulic Type |

Sliding Type |

||||

|

2 |

Φ3.5×52.5 |

1500 |

180 |

||||||

|

3 |

Φ4×56 |

2000 |

250 |

489 |

|||||

|

4 |

Φ4×60 |

2500 |

315 |

523 |

|||||

|

5 |

Φ4.3×64 |

3200 |

420 |

Excluding seals of kiln head and kiln rear |

|||||

|

6 |

Φ4.8×72 |

5000 |

630 |

Excluding kiln head cover |

|||||

|

7 |

Φ4.8×74 |

4 |

5000 |

630 |

864 |

||||

|

8 |

Φ5.2×61 |

5500 |

800 |

859 |

|||||

|

9 |

Φ5×80 |

max 3.5 |

4 |

6000 |

800 |

||||

|

10 |

Φ5.6×87 |

max 4.23 |

4 |

8000 |

800 |

1201 |

Cooperating with Burleigh Hughes |

||

|

11 |

Φ6×90 |

max 3.5 |

4 |

10000 |

845×2 |

||||

|

12 |

Φ6×95 |

max 5 |

4 |

10000 |

950×2 |

Cooperating with Smith |

CIC Reference List for Rotating Kiln

|

Client |

Size |

Qty |

Capacity of Cement Plant |

|

|

1 |

Conch Cement Group (Tong Ling) |

Ф6.3×98m |

1 |

12000t/d |

|

2 |

Conch Cement Group (Tong Ling) |

Ф6×95m |

2 |

10000t/d |

|

3 |

Conch Cement Group (Zong Yang) |

Ф6×95m |

1 |

10000t/d |

|

4 |

Conch Cement Group (Xu Zhou) |

Ф6×90m |

1 |

10000t/d |

|

5 |

Tian Rui Cement Group (Yingyang) |

Ф6.2×92m |

2 |

10000t/d |

|

6 |

Shanshui Group |

Ф6.2×92m |

1 |

10000t/d |

|

7 |

Sinoma International(Saudi Arabia) |

Ф6.2×92m |

3 |

10000t/d Parts |

|

8 |

Sinoma International(UAE) |

Ф6.2×98m |

1 |

10000t/d Parts |

|

9 |

Zhonglian Cement Group |

Ф6.2×90m |

1 |

10000t/d |

|

10 |

Conch Cement Group (Chi Zhou) |

Ф5.6×87m |

1 |

8000t/d |

|

11 |

ASTurkey |

Ф5.6×87m |

1 |

8000t/d |

|

12 |

Anhui Wanwei Co Ltd |

Ф5.0×80m |

1 |

6000t/d |

|

13 |

Nanyang Hangtian Cement Co Ltd |

Ф5.2×78m |

1 |

6000t/d |

|

14 |

Nanjing Kaisheng Engineering Comany(Turkey) |

Ф5.2×74m |

1 |

6000t/d |

|

15 |

Nanjing Kansheng Engineering Comany(Vietnam) |

Ф5.2×82m |

1 |

6000t/d |

|

16 |

Jiangsu Helin Cement Co Ltd |

Ф5×74m |

1 |

6000t/d |

|

17 |

Hongshi Cement Group |

Ф5×74m |

2 |

5000t/d |

There are many heavy equipment companies, but we are one of the best choices for you.

在线联系供应商

Other supplier products

| Calcium Carbide Furnace Tap Hole Machine | Dig furnace robot arm control has a walking mechanism, multi-station operator, hydraulic, electronic control, and other components. The operation i... | |

| CIC Mining And Cement Equipment | CIC's heavy equipment and machineryinclude not only market-leading standardized products, but also customized products and related services accordi... | |

| Calcium Carbide Furnace Tap Hole Machine | Dig furnace robot arm controlhas a walking mechanism, multi-station operator, hydraulic, electronic control, and other components. The operation is... | |

| Rotary Kiln | CIC’s equipment includes leading standardized heavy equipment and machinery products and related heavy machinery services, which can be sold ... | |

| Dry Ball Mill | Dry ball millis suitable for all kinds of metal and nonmetal ores, including materials that will react with water, such as cement, marble, and othe... |

Same products

| High Alumina Cement | 卖方: OREWORLD TRADE(TANGSHAN) CO., LTD. | What is High Alumina Cement High Alumina Cement (HAC, sometimes known as calcium aluminate cemen... | |

| Calcium Aluminate Cement | 卖方: OREWORLD TRADE(TANGSHAN) CO., LTD. | Description of Calcium AluminateCement Calcium aluminate cement, alumina cements or high alumina... | |

| CSA Cement | 卖方: OREWORLD TRADE(TANGSHAN) CO., LTD. | What Is CSA Cement? CSA (Calcium Sulfoaluminate Cement) cement is a special cement used in many ... | |

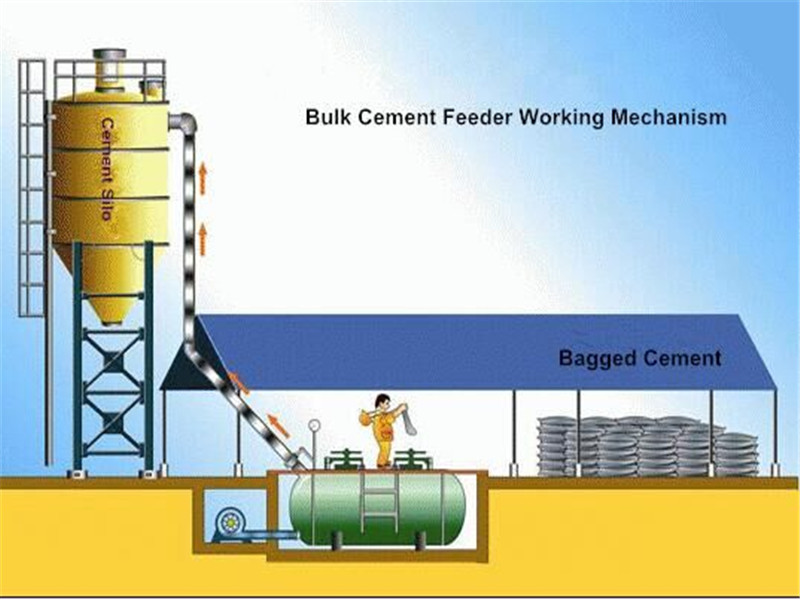

| bag cement feeding system | 卖方: Henan Shengmao Machinery Co., Ltd | Normally, we use bulk cement tanker to deliver cement to the concrete batching plant. On the bu... | |

| CSA Binder | 卖方: OREWORLD TRADE(TANGSHAN) CO., LTD. | CSA Binder Introduction: Calcium Sulfoaluminate binder is pure CSA clinker that grinded withou... |