Mirror Aluminum Composite Panel

Mirror aluminum composite panel refers to the aluminum composite panel of which surface displays a mirror effect through rolling, grinding and other methods. Generally, the

mirror aluminum composite panel

in the foreign country adopts the rolling method, which is used for making the coil material and the sheet material.

The application of mirror aluminum composite panel is very extensive. It is widely used in lighting lamps, lanterns reflective panels, decorative lamps, and lanterns, solar reflective materials, interior decoration, wall decoration, household electrical appliance panels, electronic products shell, kitchen furniture, car inside and outside decoration, signs, logos, cases, bags, jewelry box, etc.

Mirror aluminum composite panel classification

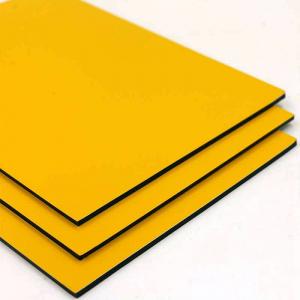

As the specifications of aluminum composite panel vary, it can be divided into many kinds. There are flat aluminum composite panel, mirror aluminum composite panel, single and double mirror aluminum and so on. It's not difficult to see that mirror aluminum composite panel can be widely applied. Its surface is very smooth. If it’s used to reflect an object, its brightness will be higher. Many people will choose this kind of material in adornment. It not only has a strong wear resistance and will not appear scratch in long-term use, but also won't appear rust.

The color of the mirrored aluminum composite panel:

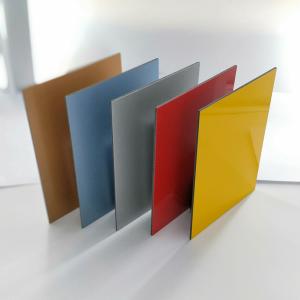

The color of the mirror aluminum composite panel can be divided into two categories: basic color and metallic color.

Base colors are: 790.36 Chinese red mirror aluminum composite panel, 790.32 orange mirror aluminum composite panel, 790.20 gold mirror aluminum composite panel, 790.50 green mirror aluminum composite panel, 790.40 blue aluminum composite panel, 790.62 cyan blue mirror aluminum composite panel, 790.42 ice blue mirror aluminum composite panel, 790.60 purple mirror aluminum composite panel, 790.18 smoked color mirror aluminum composite panel and 790.17 black mirror aluminum composite panel.

Metallic color are: 790.23 gold Titanium mirror aluminum composite panel, 790.26 champagne mirror aluminum composite panel, 790.35 Phantom copper mirror aluminum sheet, 790.30 rose gold mirror aluminum composite panel, 790.70 bronze mirror aluminum composite panel, 790.73 deep color bronze mirror aluminum composite panel and 790.16 stainless steel mirror aluminum sheet.

The advantage of mirror aluminum composite panel

Due to the special treatment of its surface during the production process, there is a protective material, so we will not have surface damaged even if we use it for a long time. These are some of its advantages, bringing us a lot of practical value. The price of mirror aluminum composite panel is also relatively low. Because it has the different function when adopted different materials, the price also varies. People can make choices according to the characteristics and operate techniques of them.

The production process of mirror aluminum composite panel

The surface treatment of the mirrored aluminum composite panel can produce the Fundamental influence on the display of panel performance. It also involves the use time of the mirror aluminum plate. So, what are the surface treatment processes of mirror aluminum composite panels?

1. Spraying:

The first step of the surface treatment of aluminum composite panel is spraying. According to the different requirements of the mirror polish, the designer will adopt different spray drying techniques. Only those aluminum plates with a uniform surface can be used as the material of the mirror aluminum plate.

2. Anti-oxidation polishing treatment:

Some users will encounter the problem of the mirror performance degradation. It's mainly caused by the nonstandard surface treatment. At the same time, the mirror coating of the aluminum composite panel is also very difficult to clean. In order to meet the user demand of different environment, the surface of mirror aluminum composite panel needs special anti-oxidation and polishing treatment.

The above is about the surface treatment process of the mirror aluminum plate. The surface treatment precision of the mirror aluminum plate has a fundamental influence on the comprehensive performance of the aluminum composite panel. The mirror aluminum composite panel with superior performance on the market have all been through retaliatory, scientific and rigorous surface treatment. The precision of aluminum composite panel processing can not only involve the decorative function of the product but also influence the market price of the product.

Tips:

The glue failure and falling off of the aluminum composite panel

The glue failure and falling off of aluminum composite panel is mainly caused by improper choose of the binder. As an ideal binder for outdoor aluminum composite panel engineering, silicone rubber has advantageous conditions. In the past, our country's silicone rubber mainly depended on imports, and the value of it was prohibitive to many people. Only the expensive curtain wall projects in the high-rise buildings can afford it. But Now, China's Zhengzhou, Guangdong, Hangzhou and other places have put different brands of silicone rubber into production, causing prices to plunge. Therefore, when purchasing aluminum composite panel, you should choose the manufacturer who uses the silicone rubber. The quick-drying adhesive used by some manufacturer will lead to the glue failure and falling off of aluminum composite panel if the panel is used in the outdoor places.

The deformation of the surface of the aluminum composite panel

It is not difficult to find out that there is the phenomenon of deformation and bubbling on the surface of ACP in many cities. The phenomenon is not only common in the small door decoration projects, but in large high-rise buildings. In the previous construction, we used to think it was the quality problem of the composite panel. But after the centralized analysis of our researcher, it was found that the main problem was on the base plate which is integrated with the aluminum composite panel. And then the cause comes to the quality of the aluminum composite panel. When purchasing the base plate, if you choose the high-density board, wood board or other flimsy panels, its service life is very short under rugged environment. Since the base material has been deformed, then the aluminum composite panel will certainly deform as the surface layer. It can be seen that the ideal outdoor base material should be the skeleton which is composed of anti-rust angle steel and square steel tube. If conditions permit, it would be ideal to use aluminum as a skeleton. The cost of the aluminum skeleton is not more than that of the wooden keel. While the project quality can be guaranteed.

在线联系供应商

Other supplier products

| Fireproof Aluminum Composite Panel | Aluminum composite panel refers to a new type of decorative materials which has a series of excellent performance. It has been widely applied in cu... | |

| PVDF Aluminum Composite Panel | The aluminum composite panel is a new type of material that has been surface-treated and coated with an aluminum plate as the surface and polyhexen... | |

| High Gloss Aluminum Composite Panel | Aluminum composite panel or aluminum-plastic panel is a kind of composite new material which has been through surface treatment and a series of tec... | |

| Company Profile | Zhejiang Jinxiang Panel Industry Co., Ltd.is located in the central area of Zhejiang province, which is adjacent to Yangtze River Delta, the most e... | |

| Mirror Aluminum Composite Panel | Mirror aluminum composite panel refers to the aluminum composite panel of which surface displays a mirror effect through rolling, grinding and othe... |

Same products

| Antimicrobial Lacquered Aluminum Foil for Insulation | 卖方: HIGH TECH VIP | Anti-microbial lacquered aluminum foilis specially developed for some buildings with high air qua... | |

| PUR PIR Sandwich Panel | 卖方: HIGH TECH VIP | PUR PIRSandwich boardsfor the construction industry are divided into a variety of insulating mate... | |

| Fumed Silica Vacuum Insulation Panels (VIP) | 卖方: HIGH TECH VIP | Fumed Silica Vacuum Insulation Panels (VIP)are high-performance thermal insulation materials prim... | |

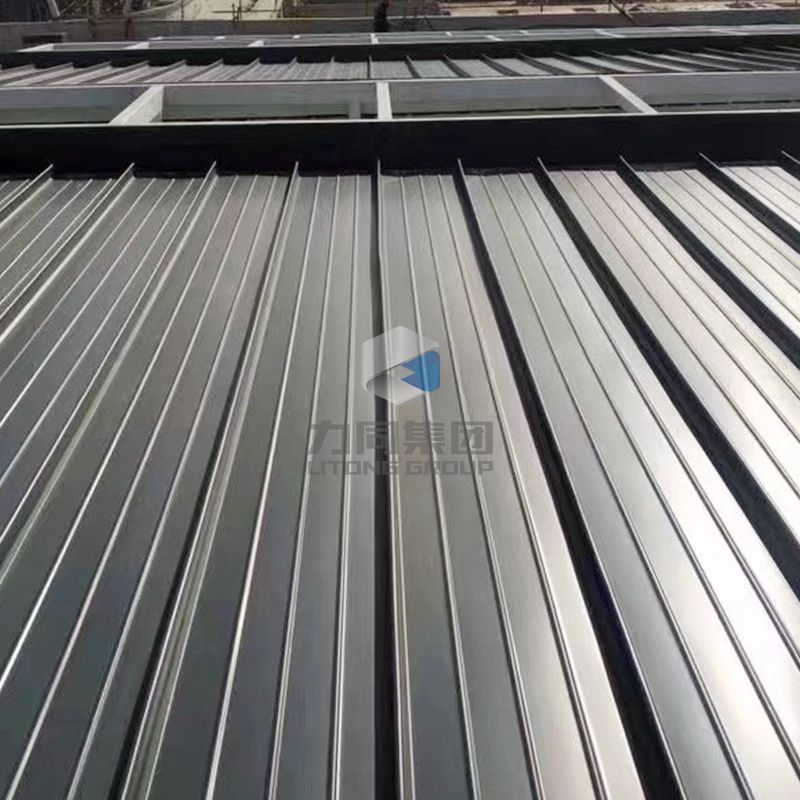

| Epoxy Coated Aluminium Coil Supplier | 卖方: LITONG ALUMINUM INDUSTRY (Wuxi) CO., LTD. | Epoxy Coated Aluminium Coil Supplier Epoxy coated Aluminium Coil is an aluminum substrate u... | |

| embossed aluminium coil | 卖方: LITONG ALUMINUM INDUSTRY (Wuxi) CO., LTD. | embossed aluminium coil Embossed Aluminum Coil is an aluminum sheet or coil with a pattern ... |