Band saw cutter using fly cutter type

Cross cutter with bang saw or disc saw

The cross cutter saw will receive a continuous processed panel from the laminator system. The saw consists of the following major items:

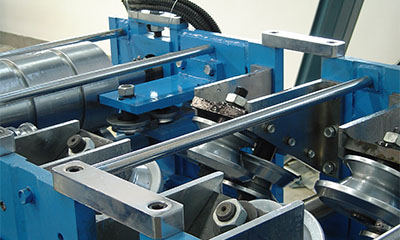

Main internal cutting frame/harp with cross travel driven by a 3 phase motor through a high quality linear guide way.

Outside main carriage with panel clamping during cutting.

Mechanical tensioning of band saw blade

Floor frame with mechanical driven return

Main control console with PLC and electrical controls

Variable speed cross cut via variable frequency drive controls

PLC and computer software batching system control.

The band saw should be located in an enclosure to minimize the affects of noise on personal nearby. This enclosure is customer supplied and manufactured from production panels from the machine

Saw operation is as follow:

On activation of a cut cycle, rubber coated clamp on the panel and travel with it while the band saw performs the cutting cycle. The band saw will then travel across the panel and cut entirely through both steel skin and the core.

The band saw could controls the speed at the joint edges of the panel, slowing the cross cut travel as it cuts through the joint areas

Once cutting is complete, the band saw will revolving after cutting for next cutting. The cutting saw can revolve, so cutting in two directions is realizable. After cutting it release the clamps and return to the home position, ready for the next cutting cycle

The main carriage will then return to the home position for the next cutting cycle

The cutting cycle can be initiated manually or by automatic length-cutting in conjunction with the central line system

This machinery is designed to cut panel during production of up to 1250 mm wide and up to 250mm thick.

Cutting machine can move 2500mm longitudinally along product line;

Band saw of the cutting machine can move transversely 1900mm, Cutting machine moves longitudinally and transversely along the slide way.

Cut length capability

Maximum cut length is only subject to transportation limitations

The dust hoods come with two openings provided on the cross-cut saw assembly. There is one catcher hood provided on the end of cross-cut saw. The dust collection system (used to pull the dust away and dispose of it) will be the responsibility of the customer.

Conveyor from band saw to cooling system machine

The band-saw out-feed conveyor is a powered roller conveyor approximately 15 meter long and approximately 1320 mm wide.

Other supplier products

供应产品

Same products