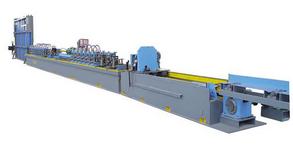

Decorative Stainless Steel Pipe Making Machine

1)BG25 Decorative Pipe Making Machine

Summary

This stainless steel pipe making machine adopts mechanical transmission roll frame structure for producing stainless steel pipes with outside diameter range of Φ8 to Φ25.4mm, thickness range of δ0.3 to 1.0mm. Main components of the steel pipe making machine include: uncoiler, forming mill, TIG welding machine, outside burrs remover, sizing and straightening equipment, fixed cutting and finished pipes collecting machine.

Producing Capacity of the Decorative Pipe Making MachineRaw material specification

|

Item |

Details |

Remark |

|

|

1 |

Coil Material |

304L, 316L series stainless steel |

|

|

2 |

Coil Thickness |

δ0.3~1.0mm |

|

|

3 |

Coil |

25~80mm |

|

|

4 |

Coil O.D. |

Φ800mm~Φ1500mm |

|

|

5 |

Coil I.D. |

Φ450mm~Φ550mm |

|

|

6 |

Coil Max. Weight |

≤1000kg |

Finished pipe specification

|

Item |

Details |

Remark |

|

|

1 |

Pipe O.D. |

Φ8mm~Φ25.4mm |

|

|

2 |

Pipe Thickness |

δ0.3mm~1.0mm |

|

|

3 |

Milling Speed |

1M/min~6M/min |

|

|

4 |

Finished Pipe O.D. Precision |

±0.05mm |

|

|

5 |

Finished Pipe Length. Precision |

±1mm |

|

|

6 |

Milling Center |

900mm |

|

|

7 |

Machine Dimension |

25m×2m (L×W) |

Working Process of the Decorative Pipe Making MachineRaw material (Steel coil) → Uncoiling → Forming → TIG welding → Outside burrs polishing → Sizing and straightening → Fixed

2)BG76 Decorative Pipe Machine

Summary

This stainless steel pipe making machine adopts mechanical transmission roll frame structure for producing stainless steel pipes with outside diameter range of Φ19 to Φ76mm, thickness range of δ0.5 to 2.0mm. Main components of the steel pipe making machine include: uncoiler, forming mill, TIG welding machine, outside burrs remover, sizing and straightening equipment, fixed cutting and finished pipes collecting machine.

Producing Capacity of the Decorative Pipe Making MachineRaw material specification

|

Item |

Details |

Remark |

|

|

1 |

Coil Material |

304L, 316L series stainless steel |

|

|

2 |

Coil Thickness |

δ0.5~2.0mm |

|

|

3 |

Coil |

60~240mm |

|

|

4 |

Coil O.D. |

Φ800mm~Φ1500mm |

|

|

5 |

Coil I.D. |

Φ450mm~Φ550mm |

|

|

6 |

Coil Max. Weight |

≤3000kg |

Finished pipe specification

|

Item |

Details |

Remark |

|

|

1 |

Pipe O.D. |

Φ19mm~Φ76mm |

|

|

2 |

Pipe Thickness |

δ0.5mm~2.0mm |

|

|

3 |

Milling Speed |

1M/min~5M/min |

|

|

4 |

Finished Pipe O.D. Precision |

±0.25mm |

|

|

5 |

Finished Pipe Length. Precision |

±3mm |

|

|

6 |

Milling Center |

900mm |

|

|

7 |

Machine Dimension |

31m×2m (L×W) |

Working Process of the Decorative Pipe Making MachineRaw material (Steel coil) → Uncoiling → Forming → TIG welding → Outside burrs polishing → Sizing and straightening → Fixed length cutting → Finished pipe collecting

3)BG114 Decorative Pipe Machine

This SS tube mill for decorative pipes adopts mechanical transmission roll frame structure for producing stainless steel pipes with outside diameter range of Φ48 to Φ114.3mm, thickness range of δ0.5 to 2.0mm. Main components of the decorative pipe making machine include: uncoiler, forming mill, TIG welding machine, outside burrs remover, sizing and straightening equipment, fixed cutting and finished pipes collecting machine.

Producing Capacity of the Decorative Pipe Making MachineRaw material specification

|

Item |

Details |

Remark |

|

|

1 |

Coil Material |

304L, 316L series stainless steel |

|

|

2 |

Coil Thickness |

δ0.8~2.0mm |

|

|

3 |

Coil |

150~360mm |

|

|

4 |

Coil O.D. |

Φ800mm~Φ1500mm |

|

|

5 |

Coil I.D. |

Φ450mm~Φ550mm |

|

|

6 |

Coil Max. Weight |

≤4500kg |

Finished pipe specification

|

Item |

Details |

Remark |

|

|

1 |

Pipe O.D. |

Φ48mm~Φ114.3mm |

|

|

2 |

Pipe Thickness |

δ0.8mm~2.0mm |

|

|

3 |

Milling Speed |

||

|

4 |

Finished Pipe O.D. Precision |

±0.5mm |

|

|

5 |

Finished Pipe Length. Precision |

±3mm |

|

|

6 |

Milling Center |

900mm |

|

|

7 |

Machine Dimension |

34m×2.5m (L×W) |

Working Process of the Decorative Pipe Making MachineRaw material (Steel coil) → Uncoiling → Forming → TIG welding → Outside burrs polishing → Sizing and straightening → Fixed length cutting → Finished pipe collecting

在线联系供应商

Other supplier products

| Completed Spiral Welded Tube Mill | DescriptionThe max 3000-120 inch series of machine is used to produce the low-pressure transporting pipe and structure pipes. The spiral welded p... | |

| Industrial Stainless Steel Pipe Making Machine | This SS tube mill for industrial pipes adopts mechanical transmission roll frame structure for producing stainless steel pipes with outside diame... | |

| Spiral Welded Pipe Hydrotester | DescriptionHydrostatic testing machine for spiral welded pipe is mainly used to have a pressure test on spiral welded pipe or straight seam welde... | |

| Straight Seam Welded Pipe Hydrotester | DescriptionHydrostatic testing machine for straight seam welded pipe is mainly used to have a pressure test on the straight seam welded pipe. T... | |

| Carbon Steel Welded Pipe Production Line | DescriptionWe can design and manufacture different series of welded pipe roll forming machine (welded pipe mill) for producing high quality strai... |

Same products

| 1435mm 数显轨距尺 | 卖方: 武汉联科瑞际轨道设备有限公司 | 铁路数显轨距尺主要用于铁路线路轨距、超高、查照间隔、护背距离 的测量。可供工务维修、大修、工程测量及其他有关部门线路作业时使用。 该仪器测量速度快、使用方便,白天、夜间均可使用,是工务、工程部门... | |

| NE-1525 Featuring Automatic Reset Battery Hydraulic Pipe Plumbing Tool | 卖方: Zhejiang Huaqi Information Technology Co., LTD | ● The automatic reset battery hydraulic pipe crimping tool is an industry- solution designed for ... | |

| DC series high efficiency european jaw crusher | 卖方: Shanghai Dongmeng Road and Bridge Machinery Co., Ltd. | Jaw crusher is widely used in ore crushing, construction aggregate production, construction waste... | |

| Internal Combustion rail drilling machine for rail construction | 卖方: 834406 | NZG-31型汽油机轨道钻孔机 该机器是铁路维护、施工和紧急维修作业中不可或缺的工具。采用空心钻头,具有快开功能的螺母夹紧机构,夹紧速度快,定位准确,钻孔快,操作简单,使用... | |

| Brown Fused Alumina For Abrasive | 卖方: ZHENGZHOU HAOYUN NEW MATERIAL TECHNOLOGY CO., LTD. | Cooled and smelted under an electric arc at a high temperature above 2000 degrees, brown fused al... |