RTQT18 automatic block production line

RTQT18 automatic block production line

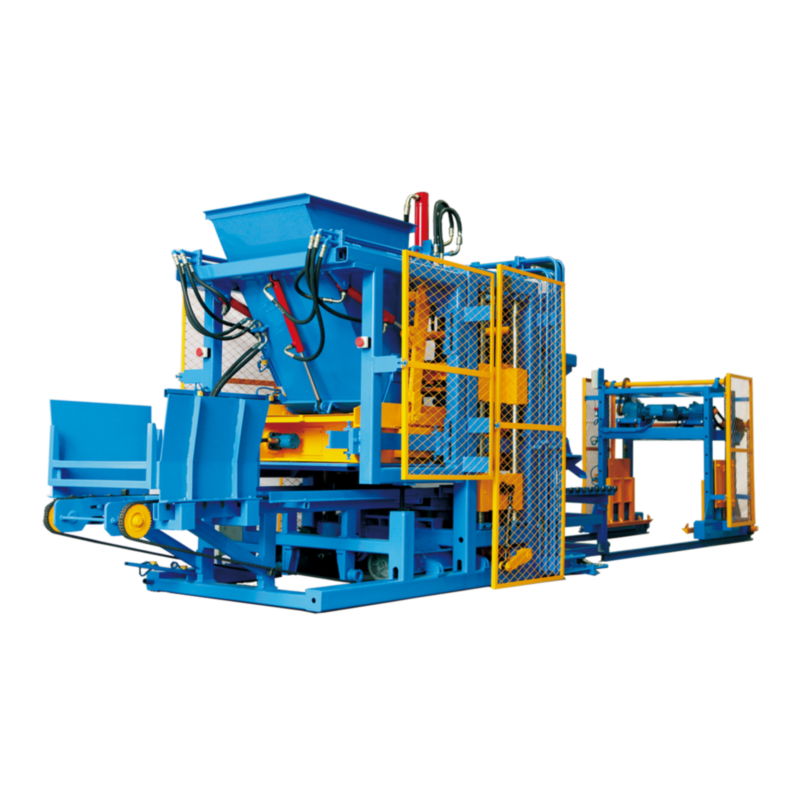

RTQT18 automatic block production line is designed, developed, processed and manufactured by REIT company on the basis of technology and process and in combination with the application of Chinese users. All key electronic control components, motor reducer, hydraulic pneumatic and other components are all foreign products, so as to ensure the high reliability of equipment operation. The equipment is more humanized in appearance design, structural design and convenient operation, which is more suitable for the use requirements of Chinese users. The performance of the cement block making machine for sale has reached the level of similar foreign products, which belongs to the general equipment for processing concrete products with excellent performance.

The core technology for stable operation of RTQT18 across the board:

The mixing system is fully automatic weighing, adopting the vertical planetary forced mixer which is most suitable for the production of dry and rigid concrete products, so that the mixing is even and fast.Microwave hygrometer ensures accurate water cement ratio.

Patented multi-axis high frequency vibration technology, with suspension vibration table to amplify the vibration power, so that the product uniform and dense. Demoulding brake device, pallet positioning device, from the details to ensure the quality of products. Hydraulic driven fast forced distribution device, durable.

The application of low speed cruise technology, motor temperature control, prolong the service life.

According to the program this device transfer the pallets with wet products and stack them automatically, two pallets once.

A frame with a gantry structure, a set of driving wheels and a set of driven wheels span the two sides of the frame body, and a liftable hanging lug is set on each of the two sides of the frame. The overall front and rear movement of the pallet truck and the lifting and lowering movement of the hanging ears are driven by the motor reducer and driven by the double-row roller chain. The hanging lug and its supporting body are hinged and can be flipped in one direction to adapt to the return process during automatic stacking. The mobile palletizer is controlled by the PLC program, which can automatically take the board according to the set parameters (number of stacks, the number of layers per stack), and automatically stack it from far to near. The stacked product stacks are transferred to the curing room by forklift trucks. The stacking level control is realized by a highly sensitive proximity switch with a prefabricated sensing block. Stacking layers and pick-and-place heights are precisely controlled by rotary encoders. In order to improve the working reliability of the equipment, a photoelectric switch is provided to detect the stacking position in time, and at the same time, it plays a role in safety protection of the equipment.

Unique 12-layer car design, the use of multiple positioning and frequency control technology combined, so that the transport process is smooth and accurate. Combined with safety technology such as self-lock and interlock, realize unattended production process.

The control system controls the entire production line, including: electric control cabinet and console. The whole control system adopts Siemens programmable logic controller (PLC) to complete the operation control of the complete set of equipment, which can realize automatic, semi-automatic and manual operation.

There is an operation terminal on the control panel, and the operator can conveniently set or change the operating parameters of the equipment on the operation console.

The control system has the function of storing a variety of different product data, and the stored data can be adjusted, modified and optimized arbitrarily, so as to reduce the debugging time after replacing the product.

Components use internationally renowned brand products, such as Siemens, Schneider, Toshiba and so on.

Provide English operating instructions and English interface of the control system.

在线联系供应商

Other supplier products

| Introduction for RTS6C block brick making machine with wholesale price | 1) STATIONARY BLOCK MACHINE REIT- RT6C RT6 CAPACITY/PER PALLET : - 6 HOLLOW BLOCKS 400×200×200MMPALLET SIZE : - 900×700×... | |

| REIT RT15A Completely Automatic Concrete Block Production Line | REIT RT15A Completely Automatic Concrete Block Production Line The automatic concrete block making machineis made by three main parts, including b... | |

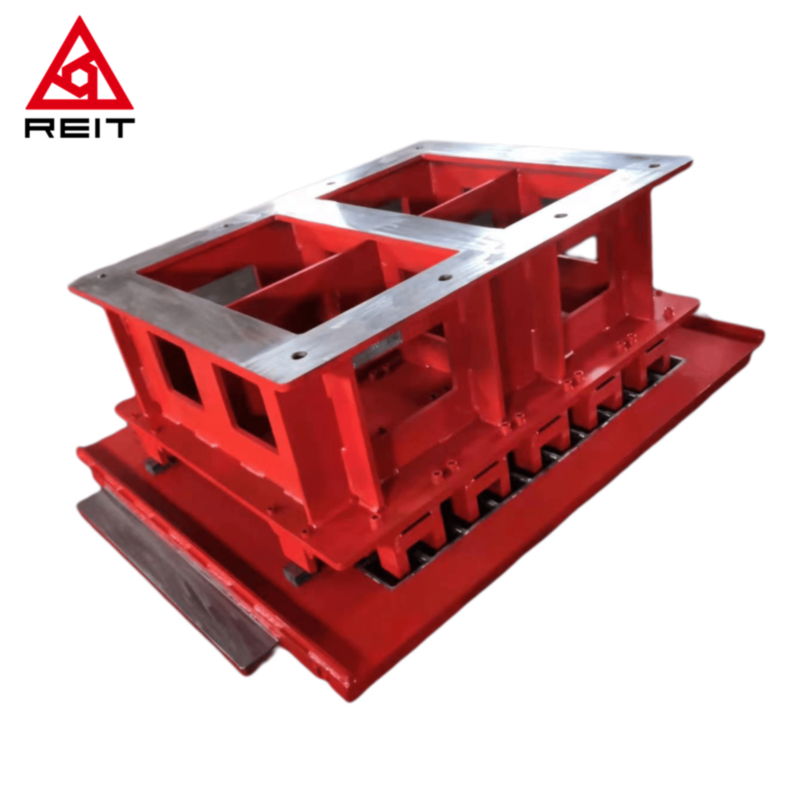

| Molds of Fly Ash / Paving Bricks & Blocks Making Machines | Molds of Fly Ash / Paving Bricks & Blocks Making Machines The block machine can produce various of bricks through changing molds. For each s... | |

| RTQT6 Fully Automatic Concrete Block Production Line | RTQT6 Fully Automatic Concrete Block Production Line The block making machine can be universally used for the manufacturing of pavers with and wit... | |

| Blender Grouped Equipment | Blender Grouped Equipment ★Concrete mixer A concrete mixer is a machine that mixes cement, sand and gravel aggregates and water into concrete mix... |

Same products

| Hydrolyzed Bovine Collagen | 卖方: Zhejiang Xinmei Biotechnology Co., Ltd. | hydrolyzed bovine collagen tabletscontains high doses of glycine, hydroxyproline, proline, and al... | |

| Introduction for RTS6C block brick making machine with wholesale price | 卖方: Beijing REIT Technology Development Co., Ltd | 1) STATIONARY BLOCK MACHINE REIT- RT6C RT6 CAPACITY/PER PALLET : - 6 HOLLOW BLOCKS 400×... | |

| RTQT12 Block Making Machine | 卖方: Beijing REIT Technology Development Co., Ltd | RTQT12 Block Making Machine RTQT12 automatic concrete block making machine can produce standard ... | |

| RTQT18 automatic block production line | 卖方: Beijing REIT Technology Development Co., Ltd | RTQT18 automatic block production line RTQT18 automatic block production line is designed, devel... | |

| REIT RT15A Completely Automatic Concrete Block Production Line | 卖方: Beijing REIT Technology Development Co., Ltd | REIT RT15A Completely Automatic Concrete Block Production Line The automatic concrete block maki... |