Points Related With the Work of Straw Pellet Mill

Different from the traditional way to make pellets, straw pellet mill is regarded as the most ideal way to make pellets. Raw materials, being delivered into the inner part of ring die, are suppressed by the press rollers and then discharged out as biomass pellets.Process to make pellets includes the work of drying, suppressing, cooling and packaging.

To finish the whole process, it needs to consume a lot of energy. Under the strong pressure varying from 50MPa to 100MPa, raw materials are suppressed into the pellets with temperature about 100-120℃.To improve theworking efficiency and output of straw pellet mill, it is better to control the humidity of raw material at about 12%.

If water content in raw material is higher or lower than 12%, work of straw pellet making machine will be seriously influenced. For many kinds of raw material, they should be dried first before the working process of straw pellet making machine.Temperature of hot pellets can reach to the degree varying from 95℃ to 110℃.

Pellets can be packaged if being cooled effectively. During the whole working process, key parts of straw pellet mill may be seriously worn out if not being maintained effectively.Known as theNO.1 brand of straw pellet machine, FTM China Machinery equips the straw pellet mill with a series of accessories for transportation, storage and supply.

By using the straw pellet mill, you will save a lot of trouble.Surprises for you on website!

Fote Heavy Machinery:

Fote Official Email:

在线联系供应商

Other supplier products

供应产品

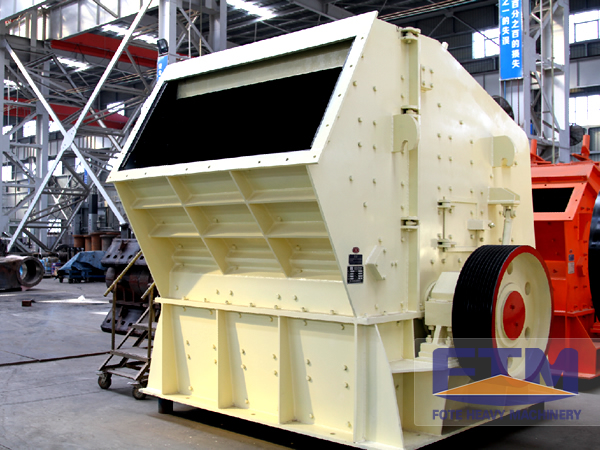

Selecting Principle for the FTM Stone Crusher

Stone crusher, mainly used for making the sand aggregates, can be used in fields like railway, building, water conservancy and mining, etc. The fol...

Different Stone Crushers in FTM Crusher Company

Based on the strong technological power and professional teams, FTM Crusher Company has produced many crushers like jaw crusher, impact crusher, ve...

Procedures to Debug the Die of Wood Pellet Press

As its name implies, wood pellet mill is a machine used to pelletize those agricultural and forestry wastes into pellets of great value. After adju...

How to Run Fote Coal Briquette Plant at Normal?

If you are troubled with the wastes like powders, scrap, waste residue such as pulverized coal, iron powder, coking coal, aluminum ash, iron filing...

Gypsum Briquetting Machine of Fote Heavy Machinery

Most people think that it is easy to make the desulfurization gypsum. Actually, it is not as simple as you image. It is technical to produce the de...

Same products

HSC Paper Sheeting Machine

卖方: Suzhou Paper Saw King Technology Co.,Ltd

HSC Paper Sheeting Machine

Product Description

HSC Paper Sheeting Machineincorporates an advanc...

Bottom Feed Slitting Rewinder

卖方: Suzhou Paper Saw King Technology Co.,Ltd

Bottom Feed Slitting Rewinder

Product Description

The bottom feed slitting rewinderreceives pap...

HX Tape Laminating Slitting Rewinder

卖方: Suzhou Paper Saw King Technology Co.,Ltd

HX Tape Laminating Slitting Rewinder

Product Description

The HX Tape Laminating Slitting Rewind...

Full Servo Band Saw Paper Slitter

卖方: Suzhou Paper Saw King Technology Co.,Ltd

Full Servo Band Saw Paper Slitter

Product Description

The Full Servo Band Saw Paper Roll Slitte...

Z1500 Circular Saw Paper Roll Slitter

卖方: Suzhou Paper Saw King Technology Co.,Ltd

Z1500 Circular Saw Paper Roll Slitter

Main Characteristics

Z1500 Circular Saw Paper Roll Slitte...