Automatic door operators

(a)Muitiple choice automatic sliding doors suitable for both internal and external environments.

(b)Anti-pinch function makes the operator more safe and more reliable.

(c)Door will be able to operate about 2000 times(open and close) during a power failure.

(d)Five different functions with remote control function keypad: Always open, half open, exit only, lock, normal open.

(e)Good solution for accessories, for example, finger printer, remote control, push button, access keypad, security sensor, fire alarm, digital wireless video entry and so on.

(f)Microwave motion detectors and safety beam protects the passengers from bumping the door, safe and reliable.

(g)A wide range of functions and options ensures that automatic doors can operate smoothly according to individual needs in various environments.

(h)Advanced smart door technology with microprocessor intelligent control, makes it suitable for all purposes.

(i)The 24V DC brushless gearmotor enables intensive usage with a very low degree of noise.

(j)Can be connected with all kinds of access control devices, make the system more safe and reliable.

2) Technical Specification ofautomatic sliding door mechanism VZ-155:

|

Gate sliding modes |

Single-opening |

Double-opening |

|

Gate leaf weight |

≤1*155 kg |

≤2*145 kg |

|

Gate leaf width |

600-1200mm |

500-1100mm |

|

Opening speed |

150-600mm/s(Adjustable) |

150-550mm/s(Adjustable) |

|

Closing speed |

120-550mm/s(Adjustable) |

120-500mm/s(Adjustable) |

|

Motor |

24V 60/100W brushless DC motor |

|

|

Hold open time |

0-9second(Adjustable) |

|

|

Special Function |

Security ,Hermetic |

|

|

Voltage |

AC220V50Hz-60Hz |

|

|

Operating Temperature |

-20°C~60°C |

|

3) Main components ofautomatic sliding door mechanism VZ-155:

|

Motor |

1 |

|

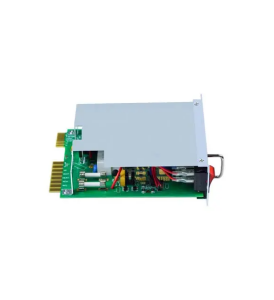

Controller |

1 |

|

Microwave motion sensor |

2 |

|

Driven wheel / Idler pulley |

1 |

|

Connector |

1 |

|

Hangers |

4 |

|

Link span(left) |

1 |

|

Link span(right) |

1 |

|

Stopper |

2 (left/right) |

|

Belt tensioner |

1 |

|

Fastenings |

1 set |

|

Aluminium beam |

2×2.1m |

|

Installation Manual&Warranty Card |

1set |

在线联系供应商

Other supplier products

| Automatic revolving door system | General introduction ofautomatic revolving door system: Product series:A wide range of automatic revolving doors for both high and low volume usage... | |

| photocell automatic sliding glass door | Specifications ofphotocell automatic sliding glass door ** ISO9001&CE certificated ** With high silicon rubber aluminum wheel hanger roller ** ... | |

| 3/4 wing automatic revolving doors | Overall features and functions of VZ-R-3/4 wing automatic revolving doors: (a)Driving system :German motor and deceleration system. (b)PLC and conv... | |

| automatic swing gate motor | Modelname: Automaticswinggatemotor,swinggateoperator,automaticdoormotor,automaticdooroperators, homeswinggateoperator,homeswinggateopener,autoswing... | |

| Automatic sliding gate motor | Model SG370 Power input AC220V±10/110V±10 (50-60Hz) Motor power 370W Maximum gate weight 500KGS Motor voltage 24V DC Gat... |

Same products

| RESSA RMD-RPB02 Mortised Automatic Door Sweep | 卖方: 黑龙江锐萨科技开发有限公司 | When the door is opened, the internal seals of RESSA automatic door sweep will automatically rise... | |

| RESSA RMD-RPB01 Mortised Automatic Door Sweep | 卖方: 黑龙江锐萨科技开发有限公司 | When the door is opened, the internal seals of RESSA automatic door sweep will automatically rise... | |

| HRTC-B1 Control Modules | 卖方: Tinko Instrument (Suzhou) Co., Ltd. | Tinko HRTC-B1 plc temperature moduleis a LED display with dual row and dual colors module. It is ... | |

| Hot Runner Control Modules | 卖方: Tinko Instrument (Suzhou) Co., Ltd. | As basic unit of hot runner control system, hot runner control module consistent temperature cont... | |

| Hot Runner Controller | 卖方: Tinko Instrument (Suzhou) Co., Ltd. | Hot runner temperature controller systemsplay a particularly important role in injection molding ... |