Forging Process

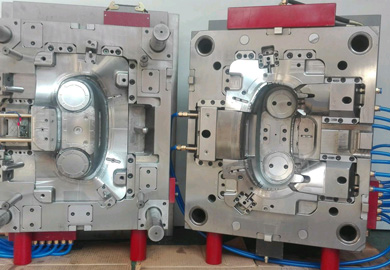

Create Die Mold

Create a die mold is the first step for the metal forging process, it is critical and essential step for the die mold forging process.

We have a die mold maker who had been working with us for near 20 years, with rich experience, who can design the mold according to customers’ drawings, samples very quickly and with very high quality.

Material Cutting and Heating

Base on the drawings or samples, our engineers will calculate the bar material diameter and length we need, then we will select the correct bar material and cut it in suitable billets.

The billets will be sent to the high frequency furnace for hearting to about 1000°C, then start the press.

Press

The heated billet with 1000° C will be put at the middle of the dies, close the dies, the material will be shaped as the customers requirement. When open the dies, we get a raw parts with the fin around.

Cutting the Fin

The raw parts with the fin will put in a cutting mold to remove the fin, after the fin removed, we get the raw forgings, the forging process is completely.

Heating Treatment

To get better strength or machining hardness, eliminate forging stress and improve metal cutting performance. we need put the forging in heat treatment furnace. Heat the parts near or above its critical temperature, held for a certain time, then cooling the metal in some medium like air, water or molten salts.

The heat treatment process includes annealing, case hardening, tempering, normalizing and quenching, nitriding, cyaniding etc.

Sand Blasting

To remove the oxide layer of the forging and get a uniformed surface, we will place the parts in sand blast machine. After sand blasting, the surface is quite uniform.

Machining

To get accurate dimensions, the machining process is needed. In my factory, with more than 40set machining, we can machine the forgings in turning, drilling, milling, grinding, that means, you just need provide the drawings or samples, we will make finished parts according to your request.

Quality Inspection

Every parts in my factory must be inspected the quality before leading to my customers. This is very important to process, we have various inspection tools and experienced inspectors in my factory. The defected parts is not allowed to ship to any customer.

Packing

Are you looking for custom forged parts? JC forging is a professional manufacturer of precision forging parts. Just contact us! We are experienced in export package, we will follow customers request to pack the parts, the plywood box or carton, pallets all available.

在线联系供应商

Other supplier products

| 5.Small Excavator Series Cylinders | What is mini excavator hydraulic cylinder? These cylinders are mainly for small excavators, including stick cylinders, boom cylinders, bucket cylin... | |

| Forged Trunnion | Product: forged trunnion Application: hydraulic cylinder, truck Place of origin: Hebei, China (Mainland) Material: C45, 20, ASTM A216 70-36 grade W... | |

| Products | Industry leaders in a variety of demanding markets continue to choose Walker Forge as a full-service partner for forgings delivered ready for duty ... | |

| Hydraulic Motor | The hydraulic motor is an actuator of the hydraulic system that converts the liquid pressure energy which provided by the hydraulic pump into the m... | |

| BM6 High Pressure Motor | What is BM6 high pressure hydraulic motor? BM6 hydraulic motor is a face-end flow, pressure-compensated motor, mainly composed of output shaft, fr... |

Same products

| Uratech : High-Quality CNC Tool Storage for CAPTO C3 holders | 卖方: Uratech USA Inc | Uratech: High-Quality CNC Tool Storage for CAPTO C3 holders When it comes to CNC tool storage, q... | |

| Mobile Counterattack All-In-One Machine | 卖方: Shanghai Dongmeng Road and Bridge Machinery Co., Ltd. | Stone Crushing Machine Factory Machinery Weight: 54-63t Max Feeding size(mm): ≤600mm | |

| Coaxial Wire Stripping Machine Automatic Rotary Stripping Machine Cable Harness Stripping Machine | 卖方: 816004 | 可编程同轴剥线机 概念:4806 是一款半自动同轴剥线机,适用于加工同轴、三轴、多芯和单芯电线。它采用最新的电子元件、用户友好的显示屏、精准的机械稳定性和卓越的剥线质量。该机器配备程序数据库和... | |

| Vinyl Exam Gloves | 卖方: 00000 | Vinyl Exam Gloves Powder Free Vinyl Exam Gloves are designed to provide a safe and economi... | |

| JN-IV850高效立式加工中心 | 卖方: 江南数控机床有限公司 | 加工灵活性,铣削、钻孔、攻丝等多种加工操作 高精度,高效率 发那科系统、三菱系统、西门子828D系统三种选择,标配原厂电机; 针对产品加工,可选择皮带式或直联式 |