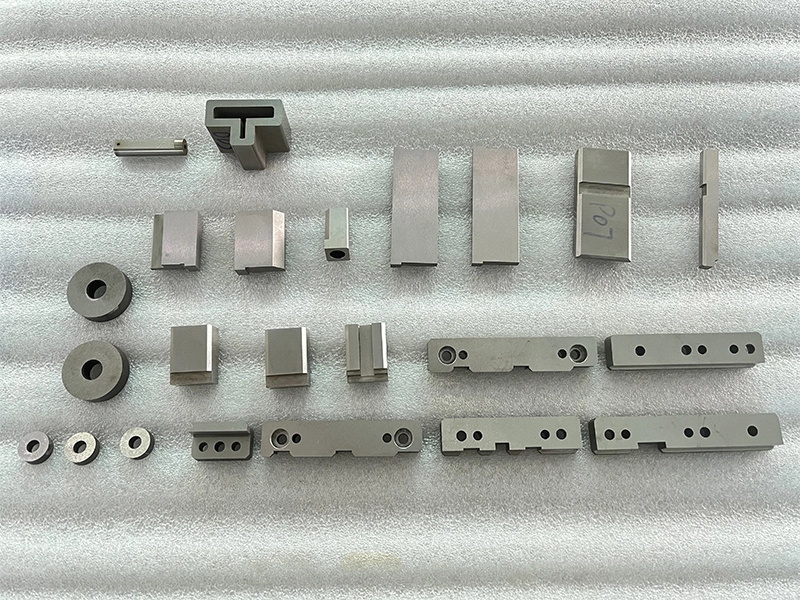

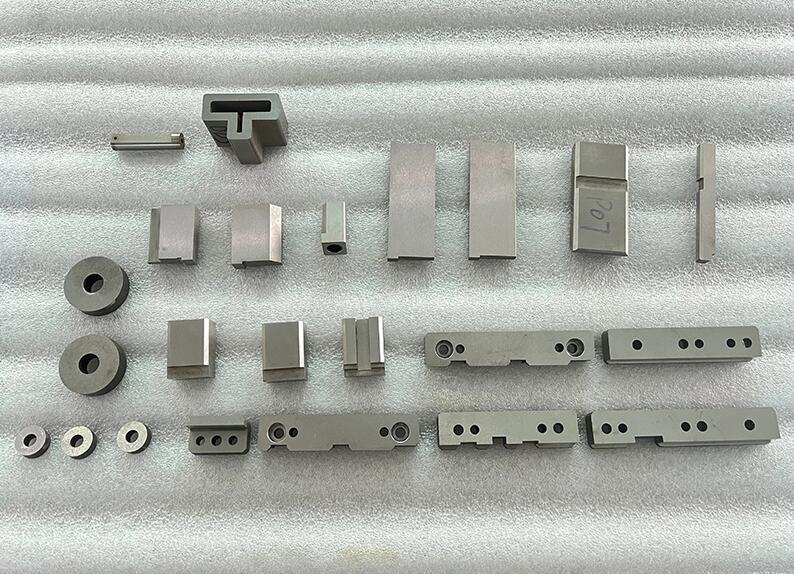

Copper Precision Spare Parts

Copper Precision Spare Parts

T1, T2 copper is mainly used as conductive, heat-conducting and corrosion-resistant components, such as wires, cables, conductive screws, shells and various conduits, etc. T3 copper is mainly used as structural materials, such as the production of electrical switches, washers, rivets, nozzles and various conduits, etc.; it is also commonly used in some less important conductive components. components.

What Materials are Available in CNC Copper?

Copper classification and characteristics

1. Pure copper in China commonly known as 'purple copper' in Japan and Taiwan commonly known as 'red copper' a common grades: T1, T2, T3, TU1, TU2 b characteristics: conductive with c common uses: electrical switches, motor coils, electronic parts.

2. Brass with zinc a Common grades: H59, H62, H65, H68, HPb59-1 Free-cutting brass b Characteristics Higher strength, wear resistance, water vapor corrosion resistance c Common uses Architectural hardware, heat exchanger tubes, pumps, power cylinders and bushings, munitions.

3. White brass: Nickel-containing Common grades: B19, B25, BFe10-1-1, BZn15-20, BA13-3 b characteristics: stable physical properties at room temperature c common use medical apparatus, precision instruments, thermocouples, watch parts, glasses frame

4. Bronze: a definition: the old name that tin bronze such as the ancient bell, tripod, wine ware New definition: purple, yellow, white copper other than the three categories of the collective name b according to the practical physical and chemical indicators such as hardness, strength, elasticity, high-temperature conductivity, thermal conductivity and so on the engineering composite index and have different formulations. c uses: tin-phosphor bronze, good elasticity, for lamps Spring piece, switch spring piece. Resistance welding electrode material roll welder, butt welder, touch welder, rivet welder. Chrome zirconium copper, beryllium cobalt copper.

About Copper CNC Machining Service

Using a computer-controlled machining tool, copper is shaped into a variety of components during the copper CNC machining process. Due to its precision and reproducibility, it is one of the most flexible and popular machining methods for copper objects. Both basic pieces with simple shapes and complicated parts with detailed shapes can be produced using this method. For applications requiring high levels of dimensional accuracy, close tolerances, and outstanding surface polish, copper machining / copper cnc machining / china copper cnc machining is appropriate.

As one of precision manufacturing companies, we can provide professional precision machining services for clients, anything you need, please contact us.

Other supplier products

|

|

Rubber Prototyping Parts |

Liquid silicone rubber (LSR) molding is a form of injection molding. The liquid silicone rubber is first injected into the mold, then the liquid is... |

|

|

Punches and Bushings Parts |

Punches and Bushings Parts

When punching holes with a concave die, the standard of hole diameter is based on the diameter of the convex die. For e... |

|

|

Alloy Precision Spare Parts |

Alloy Precision Spare Parts

Alloy titanium precision partsare components used to replace worn-out or damaged parts in a machine or apparatus. Thes... |

|

|

PEEK Non-standard Parts |

PEEK Non-standard Parts PEEK material is a new type of semi-crystalline aromatic plastic engineering plastics, with extremely good physical and mec... |

|

|

Precision Spare Parts |

We manufacture high-precision parts for customers around the world for virtually all advanced technology manufacturing industries, such as communic... |

供应产品

Same products