Load Binder

Load binder is an essential tension device to tight and secure load during transport. It is normally used together with binder chain to provide tie down and securement, protect load from dropping during dynamic movement on trucks, trailers, vans or any other transport facilities. There are lever type load binder used for straight line pull and ratchet type load binder that can give more controlled and effort-saving pull.

How is a load binder constructed?

Lever type load binder is made with a simple structure, a hinged lever and a tension hook on each end.

Ratchet type load binder is structured with ratchet gear, ratchet pawl, ratchet lever, two tension hooks with screw bolt that can be threaded in/out for take-up.

How does a load binder work?

When operate a lever type load binder, simply pull on one end of the tension hook, the lever will be hinged to take-up the slack. After 180-degree rotation of the lever around the hinge, the load binder will be locked to secure the loads.

To operate small ratchet chain binder, shaking the ratchet lever, the gears and screw will work together to increase the tension force manually and gradually.

What is the advantage of load binder?

Lever type load binder is very simple and easy for installation. It provides quick secure and release of the tension force. Super less moving parts also need very little maintenance.

small chain bindersneed very small effort to give huge tension force. It reduce the undue stress or stain on operator's body. It allows slow, but steady loading and unloading of the tension force, enable more controlled securement.

Precautions for safety use of load binder

Inspect before use. Replace worn and deformed binders.

Lubricate pivot and swivel points for optimum performance.

Always wear gloves to maintain a good grip on the binder handle.

Do not exceed working load limit

Do not operate with anyone on load. Keep out of path of moving handle

Never use cheater bars on the handle in an attempt to increase the tie down tension. Cheater bars can put excessive force on the tie down.

Always apply lever binder in a straight line hook-to-hook manner without bending and such that handle goes down when securing load.

Tighten binders before moving and re-check frequently.

Secure handle down with a positive retaining method.

Release handle / load with extreme care. Make sure everyone is clear. Lever binder handle can snap back over center. Use open palm under handle and push up.

For more detailed and professional advice aboutprecautions for safety use of load binder, you can contact Titansuhelifting equipment factory for Documents.

For more information about manual chain hoistand types of chain binders, please feel free to contact us!

There are many load binder suppliers, but we are one of the best choices for you.

在线联系供应商

Other supplier products

| Heavy Duty Stainless Steel Chain | Stainless steel chain quick linkchains are welded link chains. Made by stainless steel AISI304, AISI316 or AISI 316L, the chain surface is generall... | |

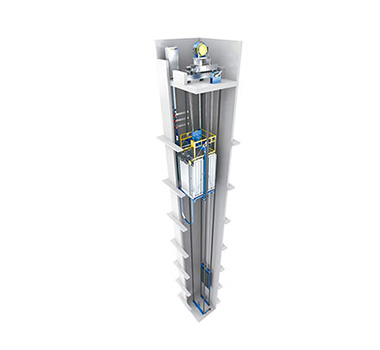

| Passenger Elevator | Passenger freight elevators are designed and rated for carring people between floors of buildings. These elevators are especially common in apartme... | |

| Aluminum Gantry Crane | As a professionalmaterial handling equipment factory, TITANSUHE's aluminium gantrycrane is made of Aluminum steel with knockdown design. All-foldin... | |

| Cargo Buckle Ratchet Straps China | As an indispensable tool in logistic industry, cargo belt straps are designed for cargo control purpose to tighten and securing cargo/equipment on ... | |

| Types of Wire Rope Pullers Cable Grips | Category and Working Principle Wire cable grip puller, wire rope cable puller including hand puller, ratchet puller, double hook tightener and cabl... |

Same products

| Load Binder | 卖方: CHONGQING TITAN SUHE TECH CO., LTD | Load binder is an essential tension device to tight and secure load during transport. It is norma... |