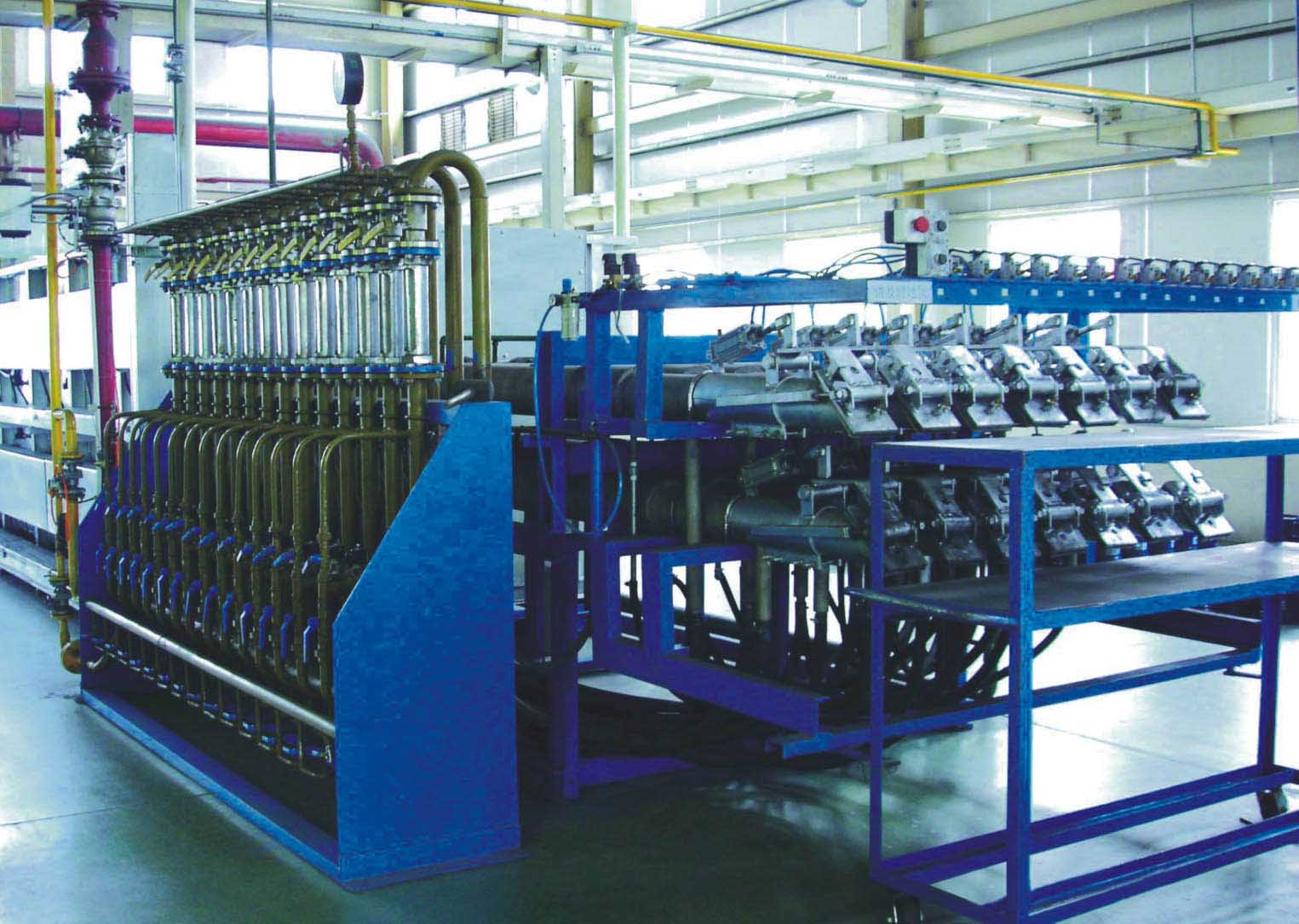

China Vacuum Sinter Furnace Manufacture

Description

Vacuum sinter furnace is mainly applied for sintering processes of tungsten alloy, magnetic, heavy alloy, moly alloy, cemented carbide, etc.

Technical Features

1. The furnace uses special hot zone structure and heating element design, which features temperature uniformity.

2. It adopts advanced refractory structure and materials, which features good insulation performance and less heat absorption. It can save more than 20% energy compare previous design.

3. The touch screen operation and PLC central control are adopted to make the operation simple and reliable.

4. Vacuum sinter furnace has functions of slow vacuum, vacuum sinter, minor positive pressure sinter and partial pressure sinter.

5. The vacuum sintering furnace has the functions of over temperature and over pressure fault alarm, mechanical automatic pressure protection and interlocking, which forms a highly safe furnace.

6. It has remote control operation, remote malfunction diagnosis and remote program update functions.

Other supplier products

|

|

全自动十八管还原炉 |

要用于金属粉末(如钨、钼等)的还原。 |

|

|

粉末冶金产品烧结炉制造商 |

该网带式烧结炉主要用于粉末冶金铁铜基零件的高温烧结,如含油轴承、齿轮、离合器片、轴瓦和衬套等零件的烧结处理。 |

|

|

China Vacuum Sinter Furnace Manufacture |

DescriptionVacuum sinter furnace is mainly applied for sintering processes of tungsten alloy, magnetic, heavy alloy, moly alloy, cemented carbide, ... |

|

|

真空时效炉 |

该真空时效炉主要用于工具钢、模具钢、高速钢、超高强度钢等材料的真空气体淬火后、固溶处理后的真空回火及有色金属的再结晶退火及真空时效等。 |

|

|

多管炉厂商 |

主要用于金属粉末(如钨、钼等)的还原。 |

供应产品

Same products