Charcoal Briquette Machine/Charcoal Briquettes Making Machine/Charcoal Briquetting Machine Supplier

Charcoal Briquette Machine, Charcoal Briquettes Making Machine, Charcoal Briquetting Machine Supplier

Usage of the Formed Charcoal Briquettes

The formed charcoal briquettes are extremely useful in industrial and civil applications. For example, they can be used as industrial fuel for smelting, casting, etc. as well as home fuel for heating. Thereby, this charcoal briquetting machine makes great contribution to improving the utilization ratio of charcoal dust. In addition, this charcoal briquetting equipment works with low energy and no pollution to the environment. It has won great popularity among users in Russia, America, India, Brazil, South Africa, etc. and created enormous benefit for them.

Handling Materials of Charcoal Briquette Machine

The ore powder ball press machine can press materials like quicklime powder, dolomite dust, copper concentrate, manganese mineral powder, laterite nickel ore, lead and zinc wastes, bauxite, nonferrous metal powder, refractory matter, ceramic materials, steel mill iron powder, converter sludge, oxide iron powder and iron sheet.

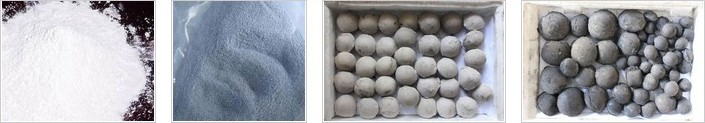

Charcoal Briquetting Process from Agro-forestry Waste

To make high quality charcoal briquettes, first of all, you must choose proper and reliable equipments from professional supplier and manufacturer. For large scale (one ton per hour and up) industrial charcoal briquetting, the following main equipments are needed: hammer mill or hammer crusher, pipe dryer, charcoal briquetting machine and carbonization furnace.

Generally, a complete charcoal briquetting process consists of the following parts:

1. Raw materials collecting is very simple because they are easy to get. Almost all kinds of agro-forestry waste can be used to make charcoal briquettes, like sawdust, crop straw, wood branches, rice hull, etc. Before briquetting, the raw materials need pre-processing so as to convenient for further processing. Here ourHammer mill is suitable for crushing different kinds of straw or wood log with size less than 200mm(diameter). After milled, the output diameter is 3-5mm, which is suitable for further briquetting.

2. Then we come to next step that is drying. As for raw materials, the moisture content is high usually more than 12%, so a sawdust dryer is necessary to help reduce the moisture content. In addition, a boiler is also needed to generates hot air and realize the purpose of drying.

3. Briquetting is the major process, and charcoal briquette machine is the core machinery. The basic principle of the briquetting machine is to compress the raw materials at high temperature and then press the material into square outside with middle empty and high density or prismatic briquette. In this process, the moisture content needs to reach 8%-12%. If the moisture content is high, the briquette may scatter; while the moisture is low, the briquette may have cracks.

4. The last step is carbonization. This process makes the wood briquette into charcoal briquette which is popular among BBQ lovers. Our furnace is of rational structure and only needs small heat consumption. The carbonized charcoal briquettes are high qualified and have longer burning time.

Charcoal Briquette Machine/Charcoal Briquettes Making Machine/Charcoal Briquetting Machine Supplier

Website:

在线联系供应商

Other supplier products

| Small Briquette Machine/Coal Briquetting Machine/Coal Briquette Machine Supplier | Small Briquette Machine, Coal Briquetting Machine, Coal Briquette Machine Supplier How to Get High Quality Final Briquettes With the purpose of en... | |

| 木屑制粒机/ FOTE新木屑制粒机/木屑制粒机 | Wood Sawdust Pellet Mill, Fote New Sawdust Pellet Mill, Sawdust Pellet Mill Sawdust Pellet Machine Description Sawdust pellet mill can press 2-8mm... | |

| Briquetting Machine/Briquetting Machine Manufacturer/Briquetting Machine | Briquetting Machine, Briquetting Machine Manufacturer, Briquetting Machine Description of Briquette Machine For Sale Briquetting Machine mainly us... | |

| Charcoal Briquette Machine/Charcoal Briquettes Making Machine/Charcoal Briquetting Machine Supplier | Charcoal Briquette Machine, Charcoal Briquettes Making Machine, Charcoal Briquetting Machine Supplier Usage of the Formed Charcoal Briquettes The ... | |

| Quicklime Briquette Press Machine/Quicklime Briquette Machine /Large Quick Lime Briquetting Machine | Quicklime Briquette Press Machine, Quicklime Briquette Machine , Large Quick Lime Briquetting Machine Development History of Quick Lime Dry Powder... |

Same products

| Blanket Flammability Test Machine | 卖方: Standard Groups | Bed Blanket Flammability Tester-It is mainly used for testing the flame retardant performance of ... | |

| High Temperature Oxygen Index Tester | 卖方: Standard Groups | The High-Temperature Oxygen Index (TOI) measuring instrument determines oxygen index at up to 125... | |

| Limiting Oxygen Index Tester | 卖方: Standard Groups | The Limiting Oxygen Index Tester measures the minimum oxygen concentration needed to sustain comb... | |

| Vertical Flammability Tester | 卖方: Standard Groups | Vertical Flammability Chamber for measuring the vertical flame spread for children’ sleepwe... | |

| 45 Degree Flammability Tester | 卖方: Standard Groups | Application 45 Degree Flammability Tester is used to determine the burning characteristics of te... |