Automobile Sealing Strip Wear Test Machine

Structural components

Friction head:

Made of wear-resistant materials, such as wear-resistant alloys, the shape and size can be customized according to test requirements, and the common size is 20×20mm.

Load device:

Generally made of high-strength steel, constant pressure is applied by adding weights, etc. to ensure stable friction conditions during testing.

Reciprocating motion mechanism: It is composed of precision-machined mechanical parts, such as motors, guide rails, transmission devices, etc., which simulate actual friction actions so that the friction head can perform continuous and stable reciprocating friction on the specimen.

Control system:

Equipped with a color touch screen, supporting Chinese and English switching, which can easily set parameters and monitor the test process. Some also have functions such as data recording, automatic shutdown, and printing test reports.

Application areas

Automobile manufacturing companies:

Conduct quality inspections on purchased sealing strips during the production process to ensure that the sealing strips used in their products meet quality requirements and improve the quality of the entire vehicle.

Sealing strip manufacturers: Used for product research and development and quality control, by testing the wear resistance of sealing strips produced by different formulas and processes, optimize production processes and product design, and improve product competitiveness.

Third-party testing agencies:

provide professional and impartial testing services to automobile manufacturers and sealing strip suppliers, issue authoritative testing reports, and provide objective basis for product quality.

Scientific research institutions:

used for related scientific research projects, research on the wear resistance of new sealing materials, explore methods and technologies to improve the wear resistance of sealing strips, and promote the development of automotive sealing technology.

Parameter

|

Test piece |

150-220mm. |

|

Friction medium |

Width: 20mm, thickness: 4mm, semi-fillet: 20 |

|

Weights |

750g |

|

Friction hammer load |

250g |

|

Speed |

0-100CPm/min. |

|

Counter |

0-999999. |

|

Size of the friction head |

20 20mm. |

|

Reciprocating stroke |

0-160mm. |

|

Power source |

AC220V,10A. |

|

Volume |

647427cm |

在线联系供应商

Other supplier products

| Photocatalysis Illumination Apparatus | Applicable standards: JIS r1702 / New ceramics - Antibacterial activity test and antibacterial effect of antibacterial processed products under li... | |

| Automotive Wires Liquid Resistance Tester | Standards: ISO 6722-1:2011: International standard for road vehicle electrical cables, specifying liquid immersion resistance. SAE J1128: Socie... | |

| Suga GX25 | GX25 is designed to artificially reproduce indoor deterioration factors such as sunlight,temperature and humidity.GX25 exposes materials to these... | |

| Paper Grammage Tester | Introduction: The circular square quantitative sampler (referred to as quantitative sampler) is a special sampler for the quantitative determinati... | |

| Car seat component clearance test bench | Applicable standards: Car seat component clearance test benches usually follow the following domestic and international standards: QC/T 805-200... |

Same products

| Air Intake Filter Test System | 卖方: Standard Groups | The Air Intake Filter Test System is designed for testing industrial air filters and engine air f... | |

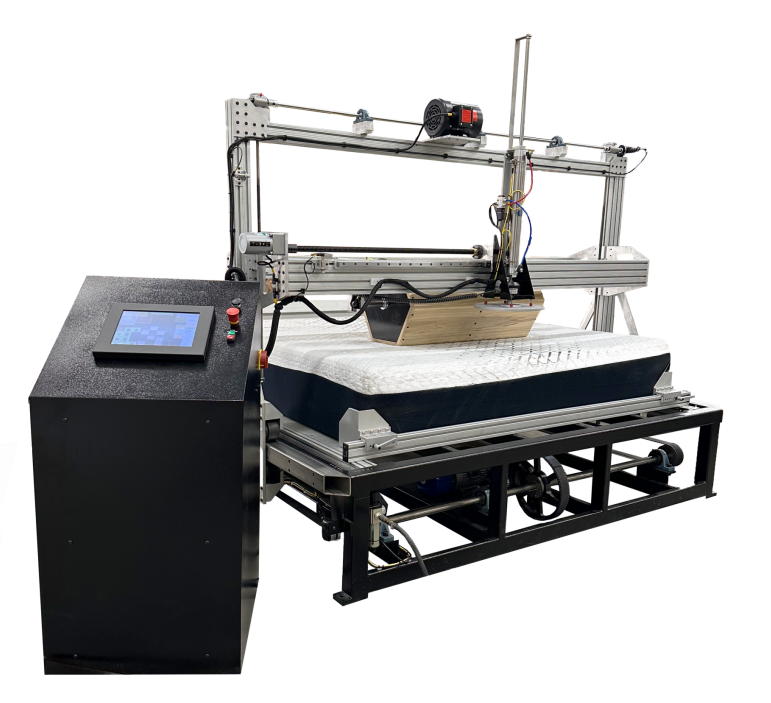

| Mattress Spring Fatigue Tester,ASTM D3574 ,how to test mattress for sagging | 卖方: Standard International Group (HK) Limited | The King Size Foam Fatigue Tester is a single-station pneumatic fatigue testing system designed f... | |

| Mattress Rollator,ASTM F1566 ,Mattress Durability Tester,Mattress Fatigue Tester | 卖方: Standard International Group (HK) Limited | The Mattress Rollator is a laboratory durability testing system designed to evaluate the long-ter... | |

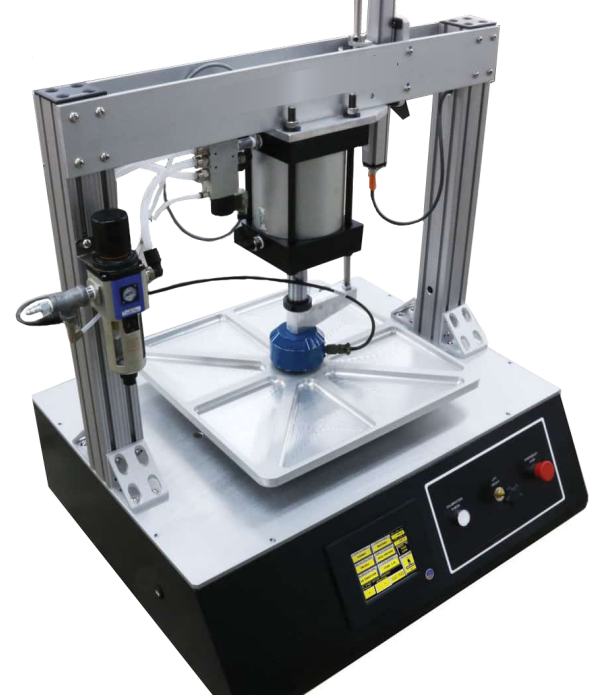

| HD2 Pneumatic Foam Fatigue Tester,ISO 3385,Foam Fatigue Testing Machine | 卖方: Standard International Group (HK) Limited | The HD2 Pneumatic Foam Fatigue Tester is a heavy-duty, single-station laboratory testing machine ... | |

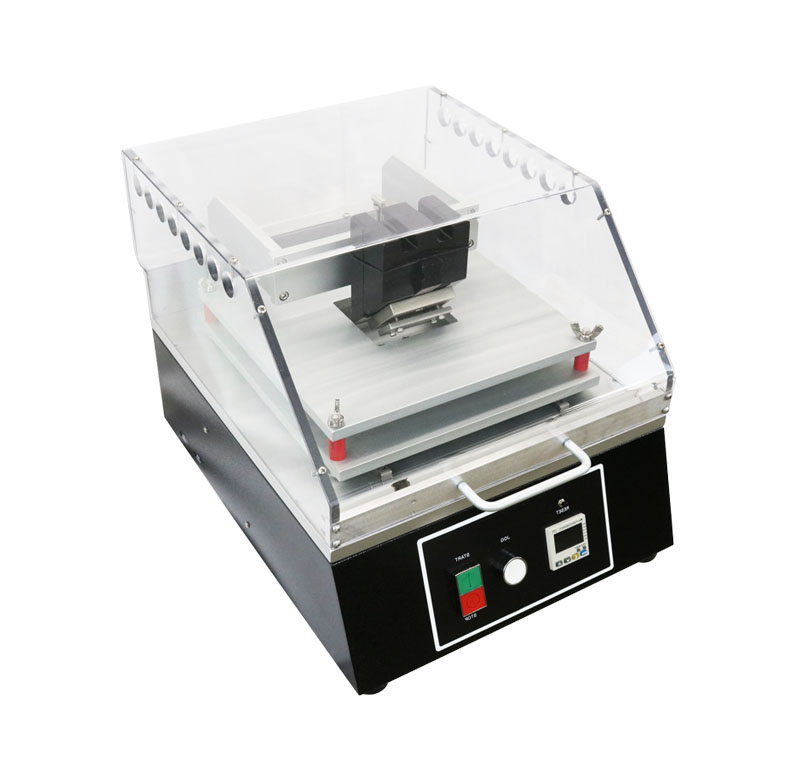

| VW Heel Abrasion Tester,ISO 4649 ,Heel Performance Testing Machine | 卖方: Standard International Group (HK) Limited | The VW Heel Abrasion Tester is designed to evaluate the wear resistance of floor covering materia... |