Electric Stacker DB12RA1、DB15RA1

Electric StackerDB12RA1、DB15RA1

Electric Stacker

ac motor forklift,Stacking equipment

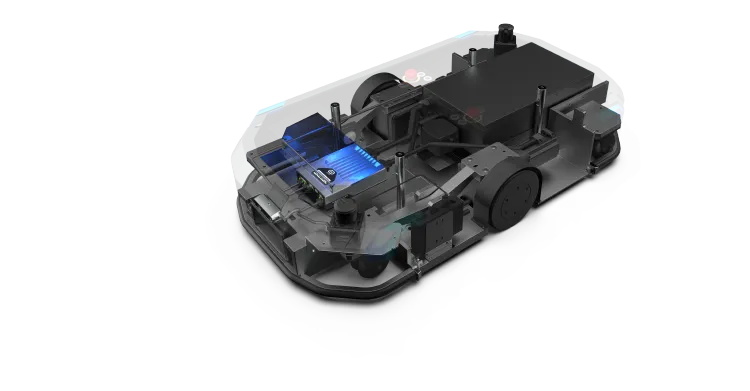

DB12RA1、DB15RA1 adopted CAN bus technology simplifies circuit and increases reliability. Vertical driving wheel ensures convenient maintenance and small turning radius. Water proof and dust-proof motor structure, keeps the braking and motor more durable and reliable.AC Motor eliminates replacement of carbon brush. Side way battery is easy to maintain.

The pallet stacker is simple in structure, flexible in operation, good in fretting, and high in explosion-proof safety performance. Suitable for operations in narrow passages and limited spaces, it is an ideal stack equipment device for overhead storage and pallet loading and unloading. Can be widely used in petroleum, chemical, pharmaceutical, textile, military, paint, pigment, coal and other industries, as well as ports, railways, freight yards, warehouses and other places containing explosive mixtures, and can enter the cabin, car and container for palletized goods Handling, stacking and handling operations. It can greatly improve work efficiency, reduce the labor intensity of workers, and win opportunities for enterprises to compete in the market. DB10M adopts fully sealed and maintenance-free large-capacity battery; ultra-small turning radius, suitable for working in tight spaces; adjustable balance wheel for increased walking stability; permanent magnet brushless motor, no carbon brush, maintenance-free; built-in .The charger is designed to make it easier and faster for customers to use. It is very convenient to replace the wheel and motor with the horizontal structure of the drive wheel. DB12RA1、DB15RA1 adopted CAN bus technology simplifies circuit and increases reliability. Vertical driving wheel ensures convenient maintenance and small turning radius. Water proof and dust-proof motor structure, keeps the braking and motor more durable and reliable.AC Motor eliminates replacement of carbon brush. Side way battery is easy to maintain.

MACHINE PARAMETERS

|

IDENTIFICATON |

DB12-RA1 |

DB15-RA1 |

|

|

Drive |

-- |

Electric(storage battery) |

Electric(storage battery) |

|

Operator type |

-- |

Pedestrian |

Pedestrian |

|

Load capacity |

Q(KG) |

1200 |

1500 |

|

Load centre distance |

c(mm) |

600 |

600 |

|

Load distance |

x(mm) |

697 |

697 |

|

Wheelbase |

Y(mm) |

1330 |

1405 |

|

WEIGH |

|||

|

Service weight(including battery) |

kg |

660/710/740/760 |

780/830/840/850 |

|

Axle loading, loaded, front/rear |

Kg |

1060/870 |

1280/1070 |

|

Axle loading, unloaded, front/rear |

kg |

560/170 |

650/200 |

|

WHEEL CHASSIS |

|||

|

Tires type |

- |

polyurethane |

polyurethane |

|

Wheel size, front |

- |

φ250*70 |

φ250*70 |

|

Wheel size, rear |

- |

φ80*70 |

φ80*70 |

|

Additional wheels |

- |

φ150*60 |

φ150*60 |

|

Wheels number front/rear(x=driven wheels) |

- |

1x+2/4 |

1x+2/4 |

|

Track width front |

b10(mm) |

586 |

586 |

|

Track width rear |

b11(mm) |

410/525 |

410/525 |

|

DIMENTION |

|||

|

Closed mast height |

h1(mm) |

2087/1837/2087/2237 |

2087/1837/2087/2237 |

|

Lift height |

h3(mm) |

1600/2500/3000/3887 |

1600/2500/3000/3300 |

|

Height, mast extended |

h4 (mm) |

2090/3060/3560 |

2087/3087/3587/3887 |

|

Height of tiller, in drive position, Min/,Max |

h14 (mm) |

1150/1450 |

1150/1450 |

|

Height, fork lowered |

h13(mm) |

90 |

90 |

|

Overall length |

L1(mm) |

1995 |

2025 |

|

Length to face of forks |

L2(mm) |

840 |

920 |

|

Overall width |

b1(mm) |

850 |

850 |

|

Fork dimensions |

s/e/l(mm) |

60/170/1070(1150) |

60/170/1070(1150) |

|

Width across forks |

b5(mm) |

580/695 |

580/695 |

|

Ground clearance, Centre of wheelbase |

m2(mm) |

28 |

28 |

|

Aisle width for pallets 1000*1200 crossways |

Ast(mm) |

2470 |

2550 |

|

Aisle width for pallets 800*1200 crossways |

Ast(mm) |

2440 |

2520 |

|

Turning radius |

Wa(mm) |

1575 |

1655 |

|

PERFORMANCE |

|||

|

Travel speed, loaded/unloaded |

Km/h |

||

|

Lift speed, loaded/unloaded |

m/s |

||

|

Lowering speed loaded/unloaded |

m/s |

||

|

Max gradeability, loaded/unloaded |

m/s |

6/15 |

6/15 |

|

Service brake |

% |

Electromagnetic brake |

Electromagnetic brake |

|

Motor |

|||

|

Drive motor power |

kw |

||

|

Lift motor power |

kw |

||

|

Battery voltage/rated capacity |

V/Ah |

24/120 |

24/200 |

|

Battery weight |

kg |

90 |

160 |

|

Others |

|||

|

Type of drive control |

- |

DC |

AC |

|

Sound level at the driver' sear according to DN12053 |

dB(A) |

70 |

70 |

在线联系供应商

Other supplier products

| Electric Reach Truck YB16R | Electric Reach TruckYB16R good quality forklift YB16Ris equipped Suspension system, imported drive unit floating design, safe and comfortable c... | |

| Electric Tractor QB30F-S、QB50F-S | Electric Tractor QB30F-S、QB50F-S QB30F-S、QB50F-S greatly reduce the center of gravity by low battery design; Steering bridge has automatic afterta... | |

| Electric Stacker DB12RA1、DB15RA1 | Electric StackerDB12RA1、DB15RA1 Electric Stacker ac motor forklift,Stacking equipment DB12RA1、DB15RA1 adopted CAN bus technology simplifies circ... | |

| Four Wheels Electric Forklift | Four Wheels Electric Forklift Forklift for port FB20H、FB25H electric forklifts also have the following characteristics when working: AC traction... | |

| Electric Stacker DB10M | Electric StackerDB10M Electric Stacker pallet truck 1500kg DB10M Using the sealed brushless motor, brushless, maintenance-free. Internally insta... |

Same products

| Small Stacker Autonomous Forklift | 卖方: Shanghai Seer Intelligent Technology Corporation | Small Stacker Autonomous Forklift Robot downloadDOWNLOAD Narrow Aisles Exclusive, Versatile a... | |

| See the latest cases | 卖方: Shanghai Seer Intelligent Technology Corporation | Build My Botarrow-icon Mobile Robot Controllers Mobile Robot Controllers Peripheral Component... | |

| Small Stacker Autonomous Forklift | 卖方: Shanghai Seer Intelligent Technology Corporation | Small Stacker Autonomous Forklift Narrow Aisles Exclusive, Versatile and Universal Built-in... | |

| Mobile Robot Controllers | 卖方: Shanghai Seer Intelligent Technology Corporation | SRC-2000-F(S) This product is dedicated to the general laser SLAM navigation controller in the... | |

| Standardize software and hardware | 卖方: Shanghai Seer Intelligent Technology Corporation | Standardize software and hardware SRC controller combined with the unified AMR OS (Robokit) and ... |