Raw Materials

Metallurgical flux coating materialrefers to the material which can separate metal from mineral by forming a low melting point slag layer while interacting with the rocks and harmful impurities in the orehe. According to the properties ofelectrode fluxmaterial, it can be divided into alkaline flux (such as limestone, dolomite, etc.), acid flux (such as quartz, metal ore with high silicone element, etc.), Neutral flux (bauxite, bauxite, etc.) and flux (such as fluorite, cryolite, etc.). It is generally required to have highly effective components, low harmful impurities. And ore strength and block degree should meet the requirements of the smelting process. Flux has the stable chemical composition, good selectivity, quick reaction, safe use, low corrosion and low price.

Other supplier products

|

|

Sodium Fluosilicate/Hexafluorosilicate (SSF) |

Sodium Fluosilicate/Hexafluorosilicate (SSF)

General Description of Sodium Fluosilicate/Hexafluorosilicate (SSF)

Molecular Formula:Na2SiF6

UN NO.: ... |

|

|

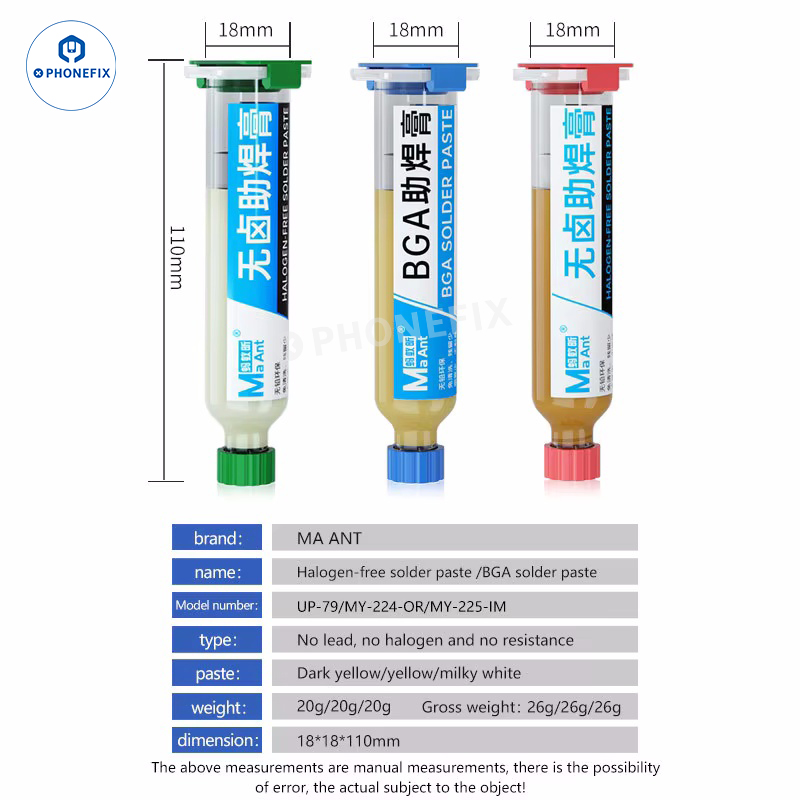

Recovery Flux |

Recovery Flux (SATA-PF-320)

General Description of Recovery Flux (SATA-PF-320)

SATA recovery flux is a kind of flux used flux for recovering the en... |

|

|

Mg Remover Flux |

General Introduction:

Magnesium plays a very important part in producing the required physical properties of many , its presence in others is not r... |

|

|

Sodium free refining flux |

General Description:

Aluminum alloys containing more than 2 % magnesium become brittle with sodium.

Sodium free refining fluxFeature: This flux is ... |

|

|

Raw Materials |

Metallurgical flux coating materialrefers to the material which can separate metal from mineral by forming a low melting point slag layer while int... |

供应产品

Same products